Sterile filter without exhaust device and use method

An exhaust device and filter technology, applied in membrane filters, chemical instruments and methods, fixed filter element filters, etc. Simple, avoid leakage, reduce the effect of manual operation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

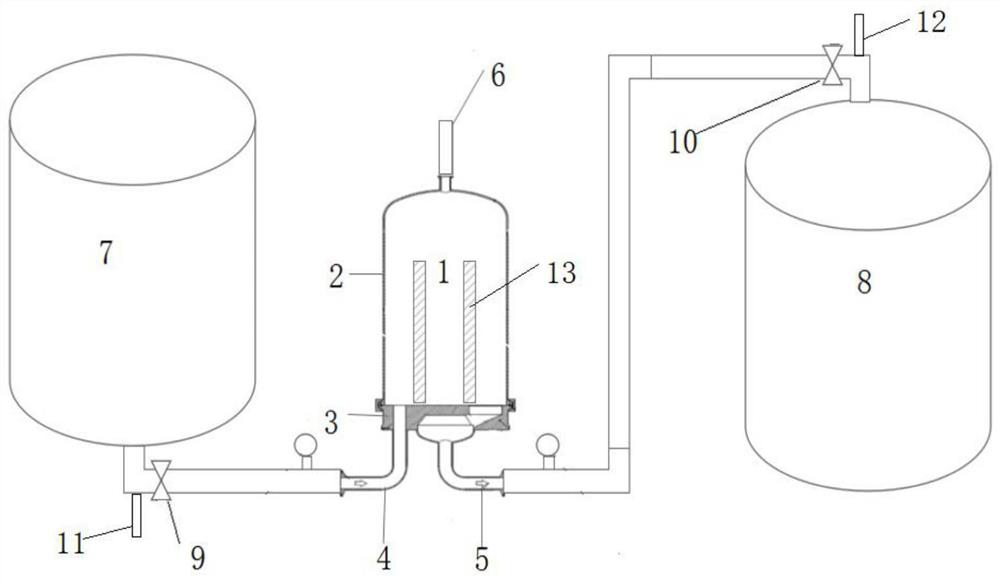

[0040] Utilize the sterile filter without exhaust device of the present application to carry out clarification and filtration to 100L of new coronavirus (SARS-CoV-2) harvest liquid. Three clarification filter elements 13 with a length of 50.8 cm and a pore size of 0.8 μm are installed inside the sterile filter 1 .

[0041] Close the liquid inlet valve 9 and the liquid outlet valve 10 to sterilize the storage tank 7 and the collection tank 8 respectively. After the sterilization is completed, all the new coronavirus harvesting liquid is passed into the storage tank 7. And ensure that the pressure P1 of the storage tank 7 is 0.04MPa, and the pressure P2 of the collection tank 8 is maintained at 0.02MPa. The sterile filter 1, the liquid inlet pipe 4 and the liquid outlet pipe 5 are sterilized online. Start the automatic sterilization program for online sterilization, and the sterilization temperature is 121°C. The sterile filter 1 is in a sealed state at the end of the sterili...

Embodiment 2

[0045] The 2000L rabies virus harvest liquid was clarified and filtered by utilizing the sterile filter without exhaust device of the present application. Fifteen clarification filter elements 13 with a length of 50.8 cm and a pore size of 0.8 μm are installed inside the sterile filter 1 . Start the automatic sterilization program for online sterilization, and the sterilization temperature is 121°C. Concrete operation is with embodiment 1. In this implementation, the pressure in the storage tank 7 is P1 is 0.05MPa, and the pressure in the collection tank 8 is P2 is 0.03MPa. The pressure P3 inside the sterile filter 1 is -0.15MPa after the sterilization is completed and the temperature is lowered to room temperature.

Embodiment 3

[0047] The 1000L 3mol / L NaCl solution was sterilized and filtered using the sterile filter without an exhaust device of the present application. Five filter elements 13 with a length of 25.4 cm and a pore size of 0.45±0.2 μm are installed inside the sterile filter 1 , and an automatic sterilization program is started for on-line sterilization at a sterilization temperature of 121° C. Concrete operation is with embodiment 1. In this implementation, the pressure in the storage tank 7 is P1 which is 0.02MPa, and the pressure in the collection tank 8 is P2 which is 0.01MPa. The pressure P3 inside the sterile filter 1 is -0.10MPa after the sterilization is completed and the temperature is lowered to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com