Liquid density sorting machine and application method thereof as well as waste plastic crushing, cleaning and sorting equipment and application method thereof

A liquid density and sorting machine technology, applied in the field of cleaning, separation process equipment, and high-efficiency crushing, can solve the problems of not mentioning the removal of impurities such as soil, limited cleaning function, etc., to achieve convenient operation, simple structure, and reduce debris. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

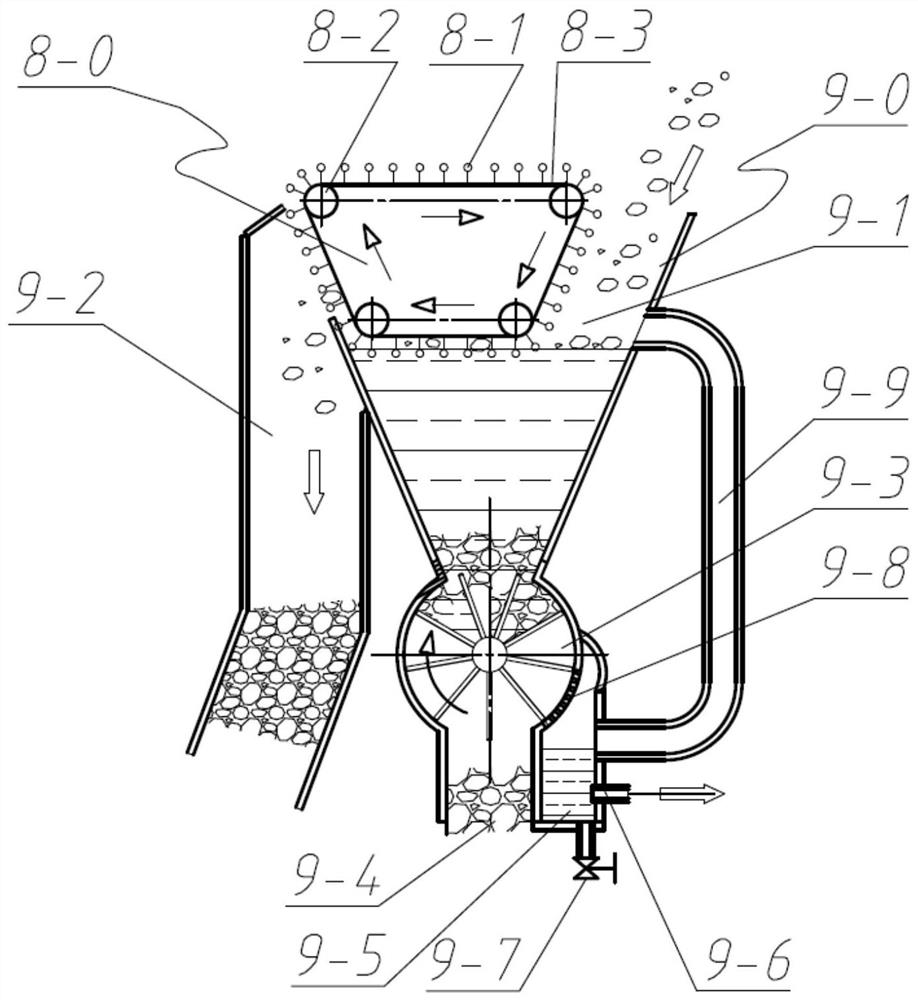

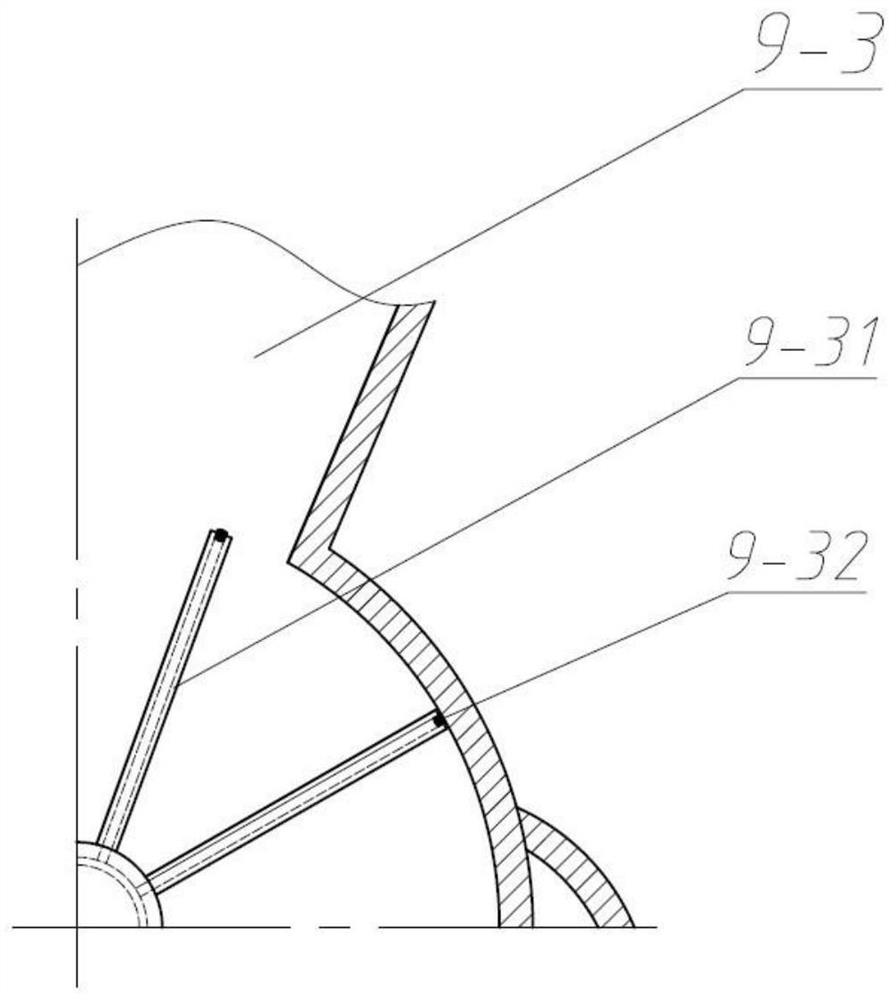

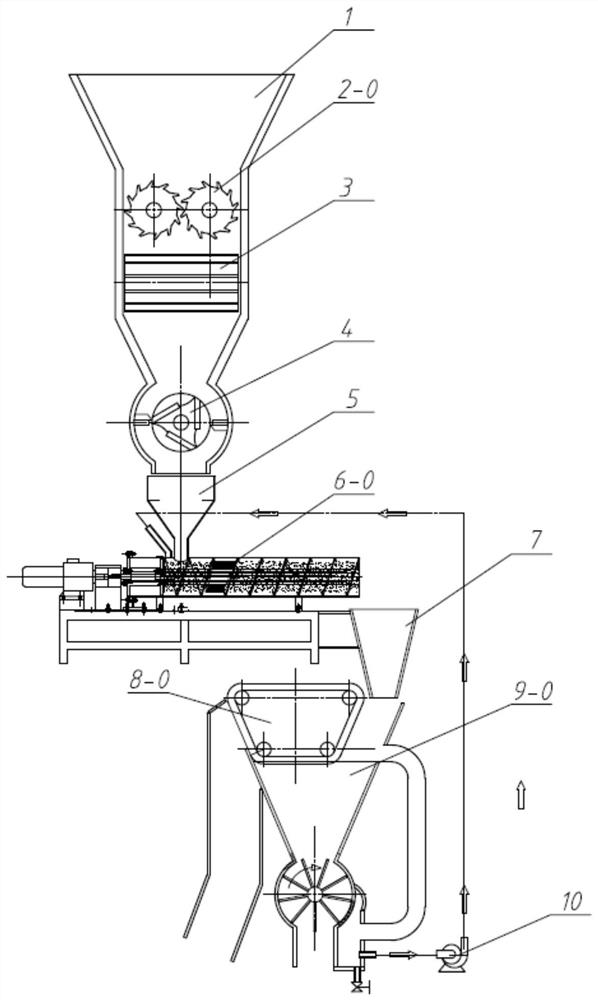

[0078] Example 1 illustrates the structure and effect of the liquid density separator and waste plastic cleaning and sorting equipment provided by the invention.

[0079] Adopt attached Figure 3 The waste plastic cleaning and sorting equipment shown in the figure carries out the crushing, cleaning and separation tests of waste plastics. The size of the first double shaft shredder is 400 × 400mm, 300mm high, 200mm diameter of tearing wheel; The structure of the second biaxial shredder is the same as that of the first biaxial shredder, and the rotating shaft of the second biaxial shredder and the rotating shaft of the first biaxial shredder are staggered by 90 ° from the top.

[0080] The rotary knife chopper has a diameter of 250mm and a length of 250mm, and the three rotary knives are evenly distributed.

[0081] The structure of the spiral hair roller cleaning machine is shown in the attachment Figure 5 As shown, the total length is 1500mm, the length of rotating shaft is 1200mm,...

Embodiment 2

[0096] Example 2 illustrates the structure and effect of the liquid density separator and waste plastic cleaning and sorting equipment provided by the invention.

[0097] The liquid density sorter and waste plastic cleaning and sorting equipment in example 1 are used for the experiment. In example 1, during the working process, the rotating speed of the first biaxial shredder and the second biaxial shredder is 250r / min. The rotating speed of the rotary knife chopper is 480r / min, and the rotating speed of the spiral hair stick cleaning machine is 60R / min.

[0098] The difference is that the waste plastic raw materials used are the separation of PVC pipe, PET bottle, PPR pipe and PS fast food box, in which the mass composition of PVC pipe and PET bottle accounts for 32.7wt%, PPR pipe and PP fast food box 39.4wt%, and the content of impurities such as soil is about 27.9wt%.

[0099] The treatment capacity of waste plastics (including impurities, filtered out with 30 mesh filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thread pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com