Mask production equipment and production process thereof

A technology of production equipment and production process, applied in the field of mask production equipment and its production process, can solve the problems of easy dispersal, extrusion and compaction of masks, affecting the use of masks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

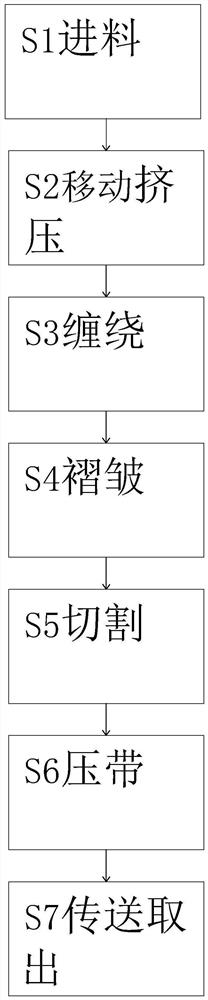

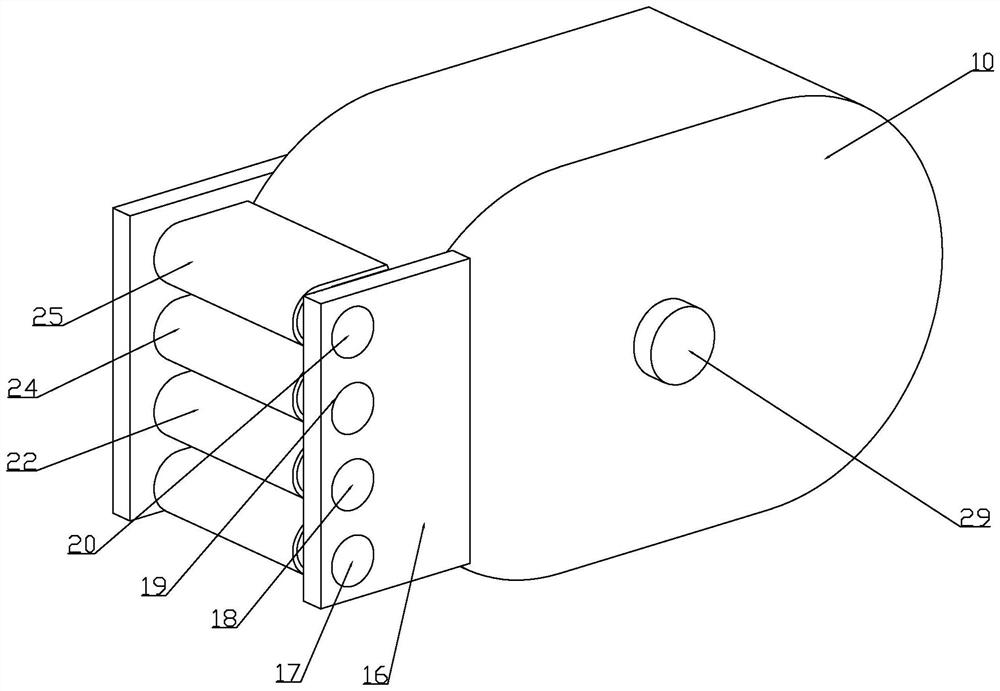

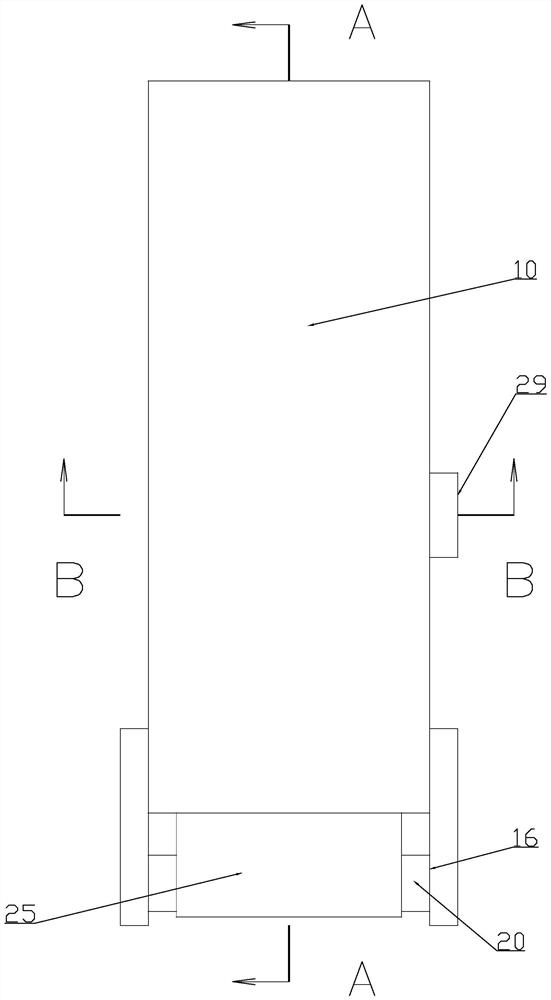

[0029] combine Figure 1-10 , a mask production equipment and production process thereof, comprising a processing box 10, a winding part 12, the winding part 12 is located in the middle of the inside of the processing box 10, and the outer side of the processing box 10 is fixed with a motor 29, and the motor 29 is directed to the processing box 10 The inner direction is fixedly provided with a linkage column 30, and the linkage column 30 is rotatably connected in the processing box 10. The outer circumference of the linkage column 30 is rotated and provided with a processing cylinder 31, and the processing cylinder 31 is fixed in the processing box 10. The lower end of the processing cylinder 31 is rotated. There is a tele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com