Non-premixed air classification low-NOx combustor

An air classification and burner technology, applied in the direction of gas fuel burner, burner, combustion type, etc., can solve the problem that the emission value of ordinary gas-fired boilers cannot meet the emission requirements, so as to reduce the residence time, improve the mixing degree, and reduce the The effect of NOx combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

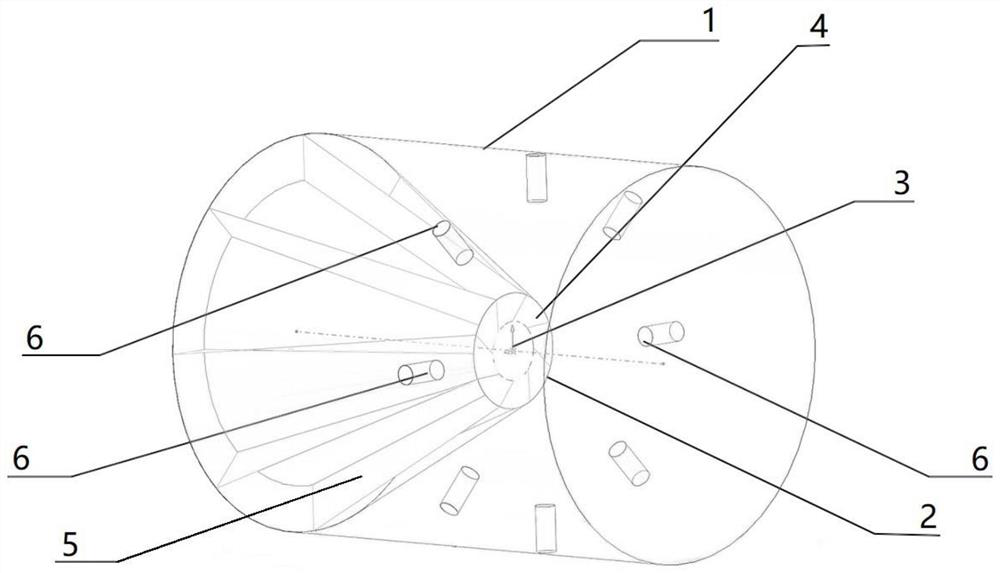

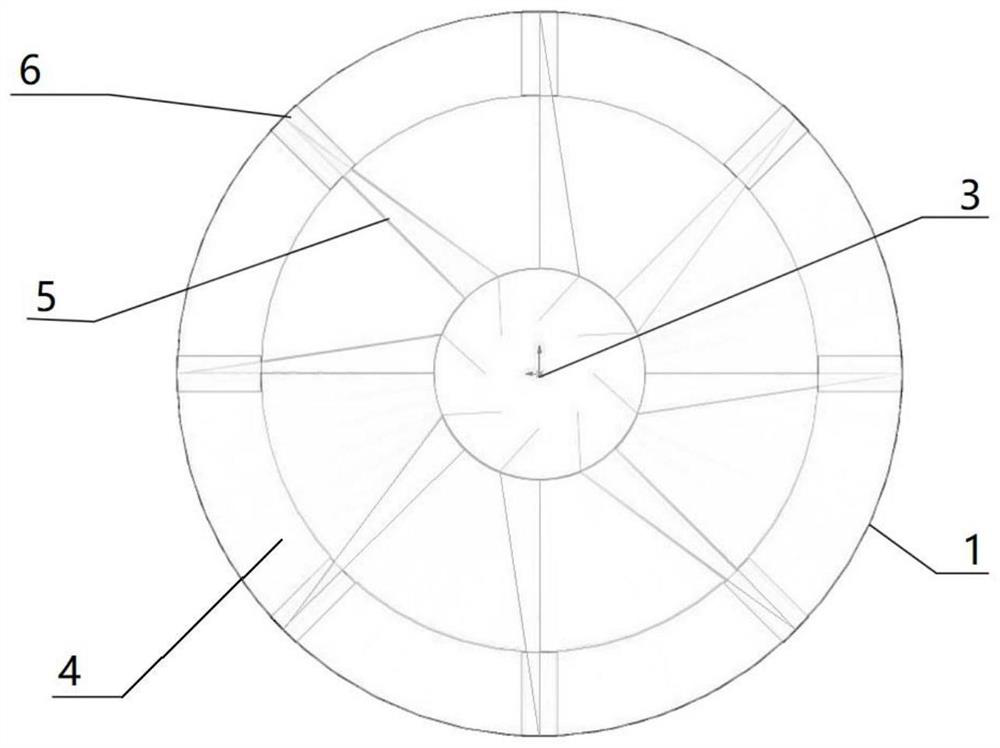

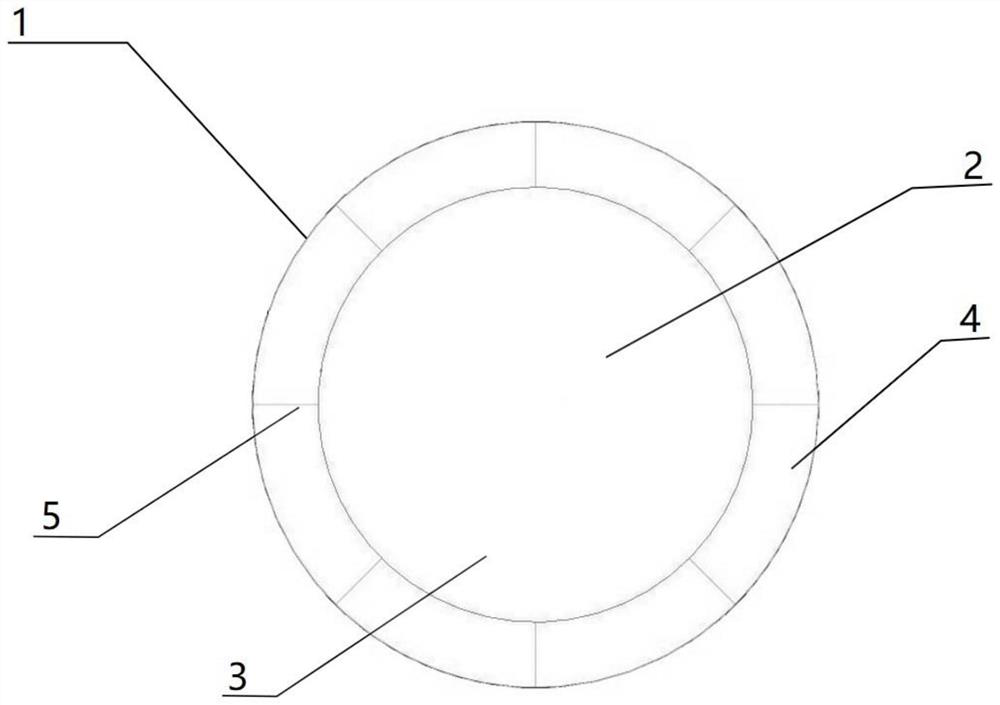

[0039] A non-premixed air staged low NOx burner 1 such as Figure 1-8 As shown, it includes a non-premixed passage 2 arranged inside the burner 1 and a secondary air passage 6 arranged on the side wall of the burner 1; the non-premixed passage 2 includes a gas passage 4 and an air passage 3; the air passage 3 and the The non-premixed channel 2 is coaxially arranged, the gas channel 4 is the annular gap between the air channel 3 and the non-premixed channel 2; there are several secondary air channels 6, which are arranged at the outlet of the non-premixed channel 2 along the circumferential direction On the side wall of the burner 1 at the front end.

[0040] More specifically, in this example:

[0041] The amount of air entering the burner 1 through the air passage 3 is 80% of the theoretical air amount of the complete combustion of the gas, so that the flame temperature generated by the combustion of the gas is lower, thereby reducing the emission of thermal NOx; at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com