Experimental device for observing cold shock cracking coal body in whole process

An experimental device, cold shock technology, applied in the direction of measuring devices, fuel oil testing, material inspection products, etc., can solve the problems of insufficient technology, lack of observation instruments for coal energy, structural changes, etc., and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

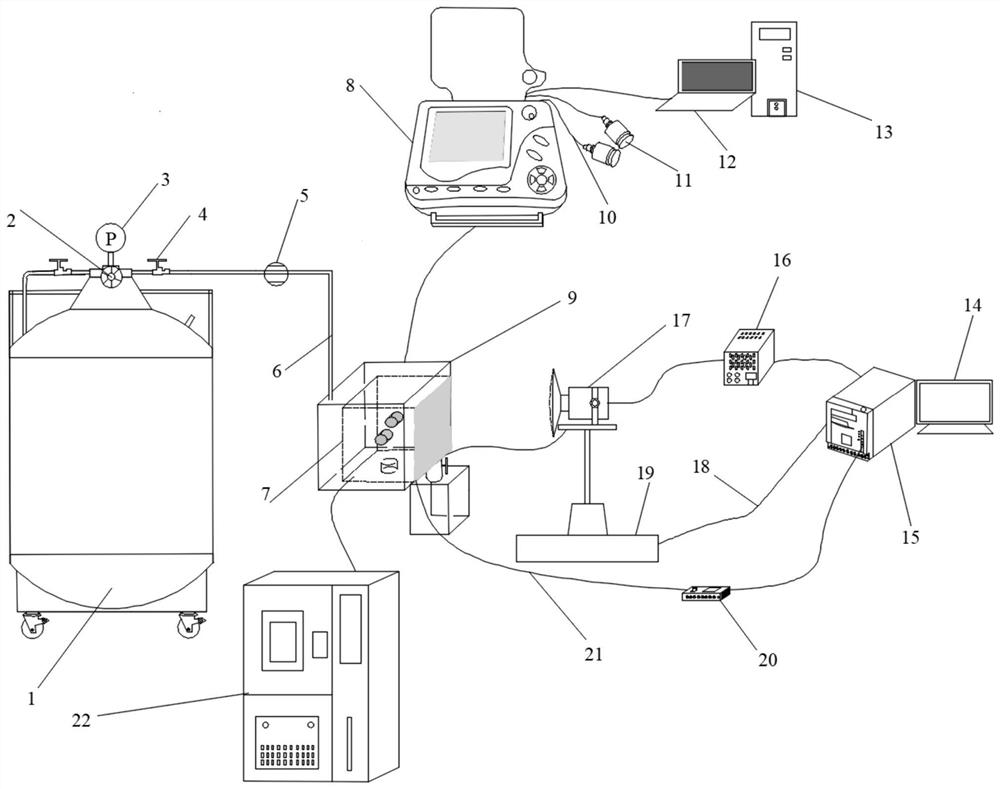

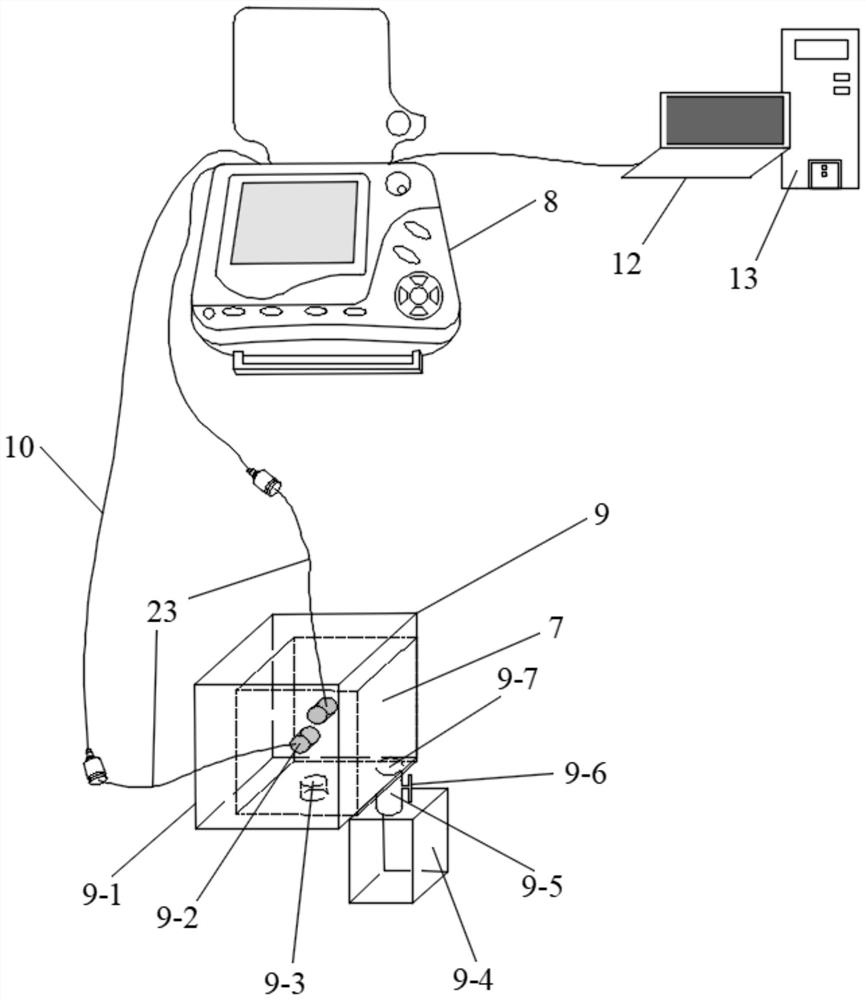

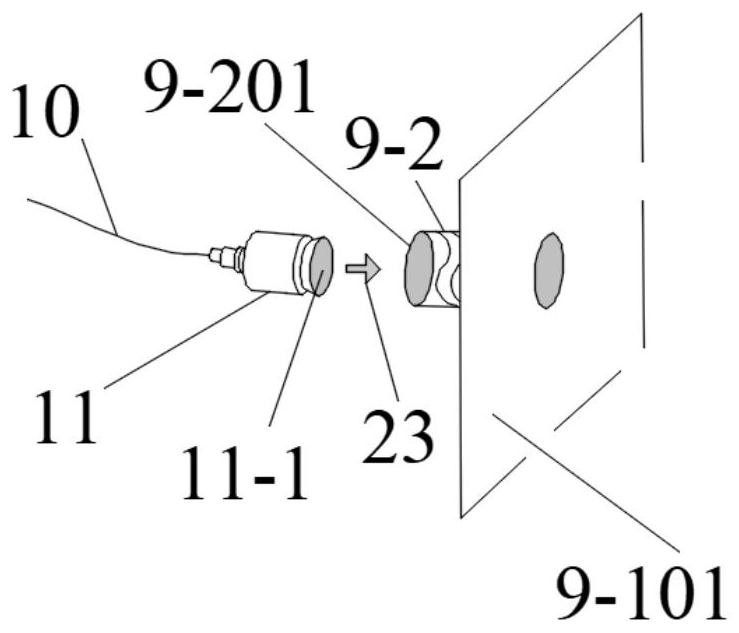

[0033] An experimental device for observing cold shock fracturing coal bodies in the whole process, such as figure 1 As shown, it includes coal sample storage system, liquid nitrogen injection system, liquid nitrogen cold impact system, ultrasonic acquisition and processing system and thermal imaging acquisition and processing system.

[0034] The coal sample storage system is composed of a constant temperature and humidity box 22 and a coal body 7 , and the coal body 7 is placed in the constant temperature and humidity box 22 . After the coal body 7 is prepared according to the required experimental conditions, the temperature and humidity of the constant temperature and humidity box 22 are set, and the coal body 7 is put in for standby. The coal body 7 is a cube of 70×70×70 mm.

[0035] Such as figure 1 As shown, the liquid nitrogen injection system consists of a self-pressurized liquid nitrogen tank 1, a valve 2, a pressure gauge 3, a pressure regulating valve 4, an ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com