3DP printing method based on purple sand

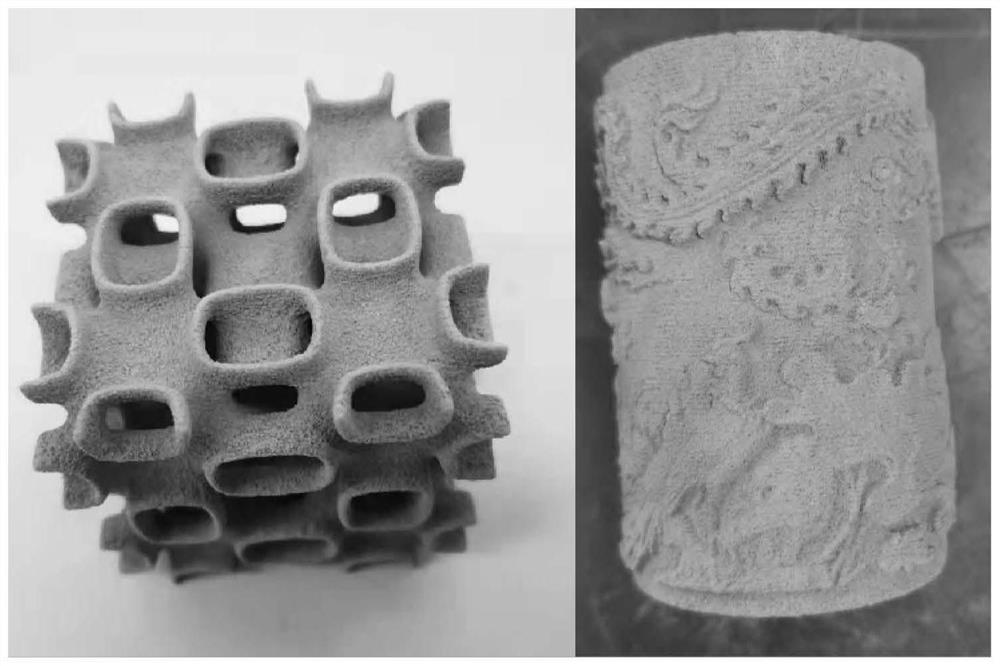

A 3DP, purple sand technology, applied in the field of additive manufacturing, can solve the problems that the purple sand mud paste cannot be stored for a long time, cannot print fine models, and the texture of the outer layer of the model is heavy, and achieves good market prospects, simple and easy to implement and easy to save. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Prepare 3DP printing powder materials according to the following mass percentages:

[0026] Zisha raw ore particles 55%

[0027] Zisha mud dry powder 37%

[0028] Polyvinyl alcohol 8%

[0029] The dried purple sand raw ore is directly crushed and ground, and sieved to obtain purple sand raw ore particles with a mesh size of 80 mesh to 200 mesh. Dry or air-dry the stale purple sand mud strips or mud blocks, grind them, and pass through a 200-mesh sieve to obtain dry powder of purple sand mud with a size of more than 200 mesh. Then weigh each powder raw material as required, mix evenly, and prepare 3DP printing powder material.

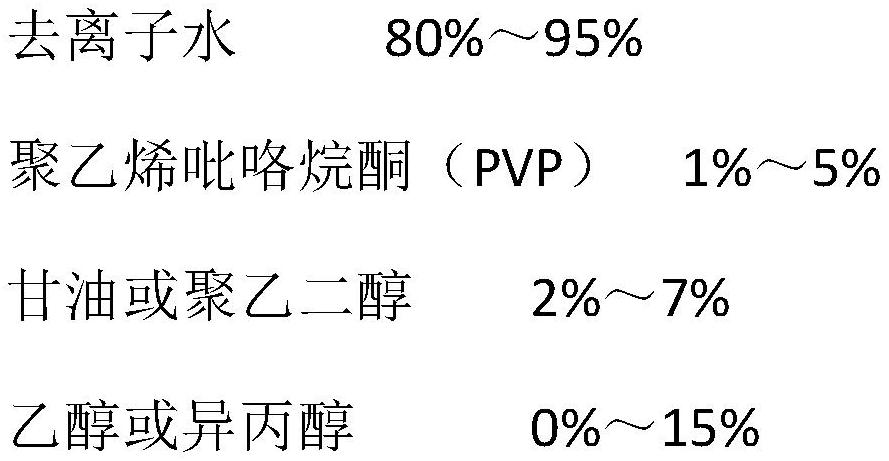

[0030] (2) Prepare 3DP printing binder according to the following mass percentage:

[0031]

[0032] The above raw materials are weighed by mass, mixed evenly until transparent, and the 3DP printing adhesive is prepared.

[0033] (3) 3DP printing

[0034] Put the prepared 3DP printing powder material and 3DP printing binder into the ...

Embodiment 2

[0038] (1) Prepare 3DP printing powder materials according to the following mass percentages:

[0039] Zisha raw ore particles 85%

[0040] Zisha mud dry powder 5%

[0041] Polyvinyl alcohol 10%

[0042] The dried purple sand raw ore is directly crushed and ground, and sieved to obtain purple sand raw ore particles with a mesh size of 80 mesh to 200 mesh. Dry or air-dry the stale purple sand mud strips or mud blocks, grind them, and pass through a 200-mesh sieve to obtain dry powder of purple sand mud with a size of more than 200 mesh. Then weigh each powder raw material as required, mix evenly, and prepare 3DP printing powder material.

[0043] (2) Prepare 3DP printing binder according to the following mass percentage:

[0044]

[0045] The above raw materials are weighed by mass, mixed evenly until transparent, and the 3DP printing adhesive is prepared.

[0046] (3) 3DP printing

[0047] Put the prepared 3DP printing powder material and 3DP printing binder into the ...

Embodiment 3

[0051] (1) Prepare 3DP printing powder materials according to the following mass percentages:

[0052] Zisha raw ore particles 65%

[0053] Zisha clay dry powder 22%

[0054] Polyvinyl alcohol 13%

[0055]The dried purple sand raw ore is directly crushed and ground, and sieved to obtain purple sand raw ore particles with a mesh size of 80 mesh to 200 mesh. Dry or air-dry the stale purple sand mud strips or mud blocks, grind them, and pass through a 200-mesh sieve to obtain dry powder of purple sand mud with a size of more than 200 mesh. Then weigh each powder raw material as required, mix evenly, and prepare 3DP printing powder material.

[0056] (2) Prepare 3DP printing binder according to the following mass percentage:

[0057]

[0058] The above raw materials are weighed by mass, mixed evenly until transparent, and the 3DP printing adhesive is prepared.

[0059] (3) 3DP printing

[0060] Put the prepared 3DP printing powder material and 3DP printing binder into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com