Ultrahigh-toughness cast aluminum alloy and forming method thereof

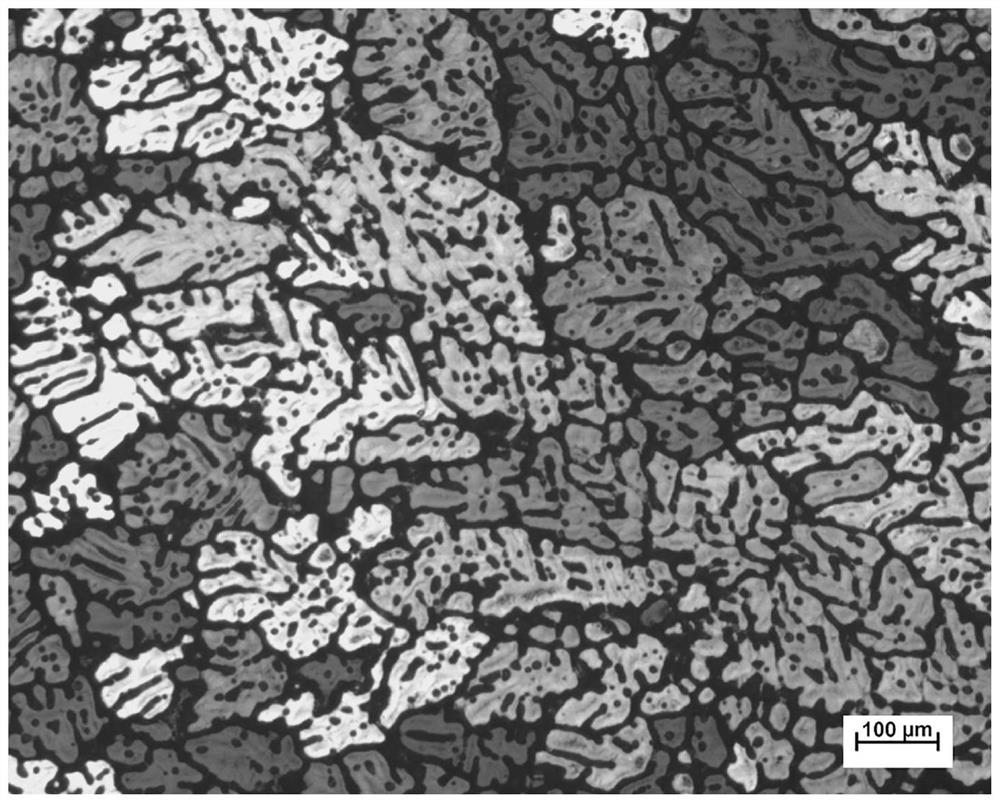

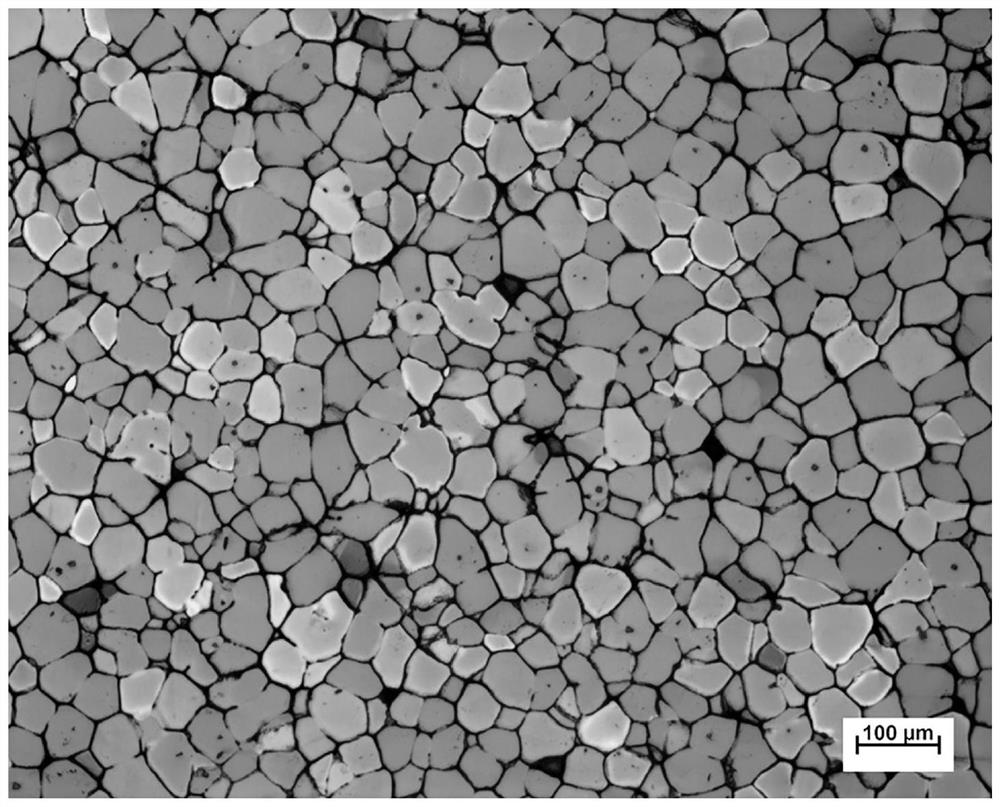

A casting aluminum alloy, ultra-high strength and toughness technology, applied in the field of high-performance casting aluminum alloy materials and its processing, can solve problems in the laboratory research stage, etc., to achieve changing the solidification mode of the alloy, inhibiting dendrite growth, and excellent toughness properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

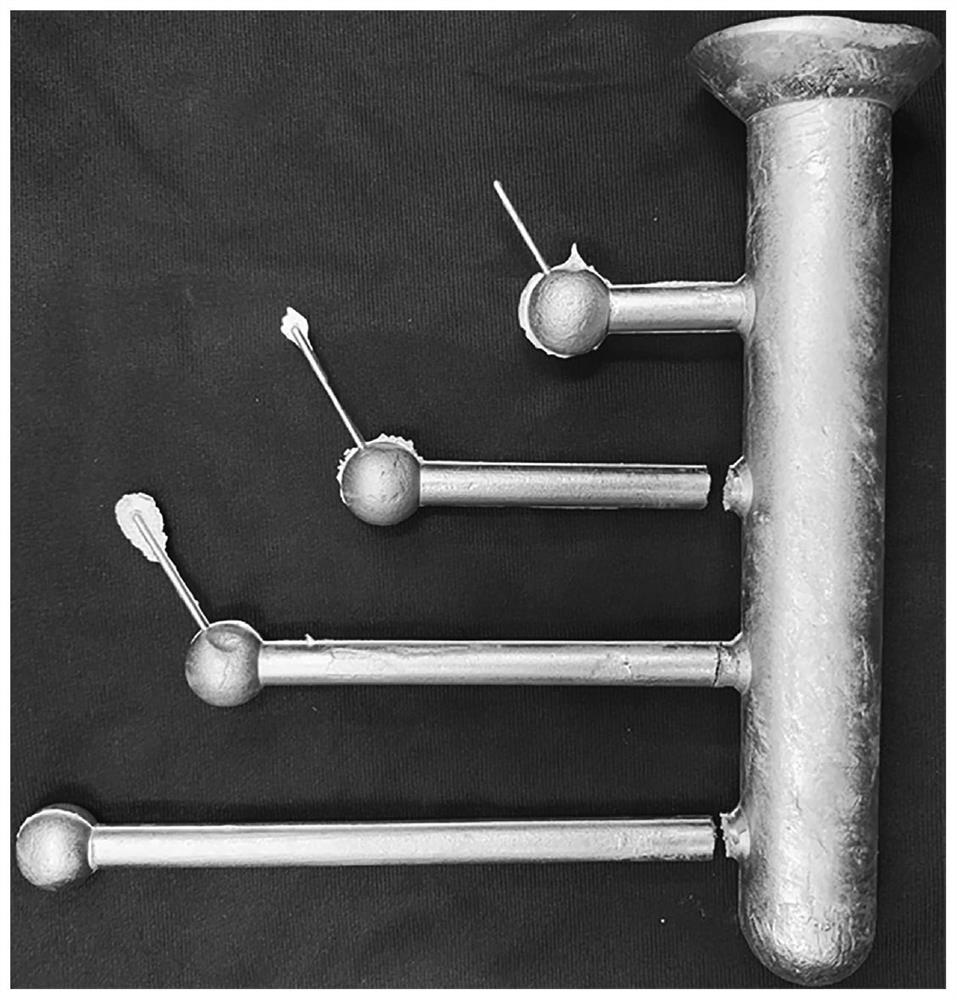

Examples

preparation example Construction

[0050] The preparation method specifically comprises the following steps:

[0051] (1) Raw material preparation: use high-purity metal Al, high-purity metal Zn, high-purity metal Mg, high-purity Al-Cu master alloy, high-purity Al-Zr master alloy and high-purity Al-Sc master alloy as raw materials, according to Al -The weight percentage of Zn-Mg-Cu-Zr-Sc alloy composition: Zn 7.6~8.6%, Mg 1.8~2.4%, Cu 1.1~1.7%, Zr 0.1~0.2%, Sc 0.1~0.2%, the rest is Al, And the unavoidable impurity Fe content≤0.06%, Si content≤0.06%, and the total amount of other impurities≤0.15%.

[0052] Wherein, the Cu content in the Al-Cu master alloy is 30-50% by mass percentage, and the balance is Al;

[0053] The Zr content in the Al-Zr master alloy is 3-5% by mass percentage, and the balance is Al;

[0054] The content of Sc in the Al-Sc master alloy is 1-2% by mass percentage, and the balance is Al.

[0055] (2) Alloy smelting: Mix the above metals and intermediate alloys for smelting at a melting te...

Embodiment 1

[0064] A high strength and toughness casting Al-8.14Zn-1.93Mg-1.56Cu-0.11Zr-0.13Sc alloy, its chemical composition (wt.%) is: Zn 8.14, Mg 1.93, Cu 1.56, Zr 0.11, Sc 0.13, and The amount is Al.

[0065] Preparation methods include:

[0066] (1) Raw material preparation: Al, Mg and Zn are added in the form of high-purity metals, and alloying elements Cu, Zr, and Sc are all added in the form of high-purity aluminum-based master alloys;

[0067] (2) Alloy smelting: using resistance furnace and graphite crucible, after the metal materials (pure Al and its intermediate alloys Al-50Cu, Al-5Zr, Al-2Sc) are completely melted during smelting, metal Zn and Mg are covered with aluminum foil Finally, use a bell jar to press into the bottom and keep stirring to completely melt. In order to fully melt the existing coarse intermetallic compound particles in the master alloy, the melting temperature was set at 780°C and the holding time was 20min.

[0068] (3) Alloy refining: after the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com