High-temperature-resistant ceramic coating graphite tray assembly

A technology for high-temperature resistant ceramics and graphite trays, applied in coatings, metal material coating processes, gaseous chemical plating, etc., can solve the problems of scrapping graphite tray components, corrosion holes, and damage to tray surface coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

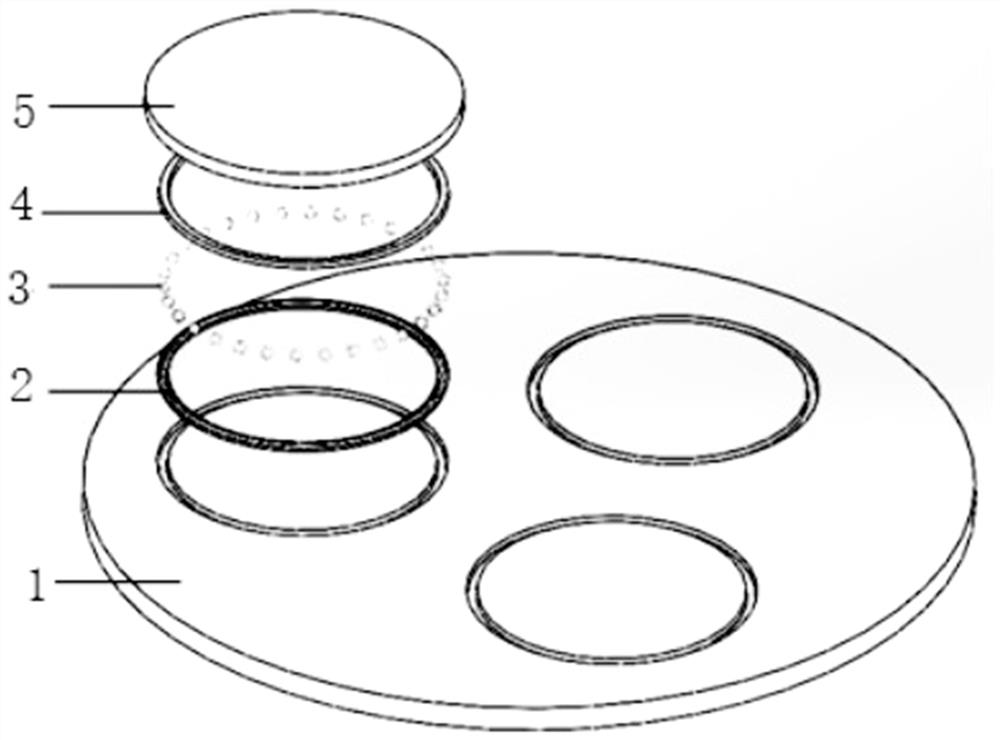

[0046] The embodiment of the present invention provides a high-temperature resistant ceramic coated graphite tray assembly, including: a carrying plate 1, a number of supporting and fixing devices, a number of trays 5, and a mechanical drive mechanism;

[0047] A plurality of trays 5 are connected to the carrying tray 1 through several supporting and fixing devices (several supporting and fixing devices, and several trays 5 are arranged in one-to-one correspondence), and the mechanical drive mechanism is used to drive the carrying tray 1 and the trays 5 turn.

[0048] Preferably, specifically, the support and fixing device includes:

[0049] The first circular groove is arranged on the carrying large plate 1, the first ball track 2 is laid on the first circular groove, the first ball track 2 is filled with balls 3, and the tray 5 is provided with a second circular groove or a second ball track 4 that cooperates with the ball 3; wherein, the size and shape of the second ball t...

Embodiment 2

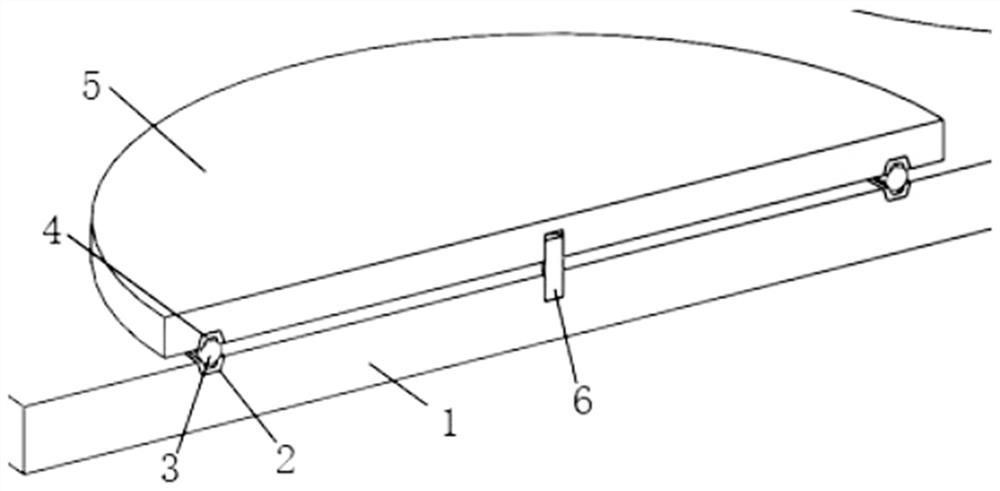

[0058] The embodiment of the present invention provides a high-temperature resistant ceramic coated graphite tray assembly, including: a carrying plate 1, a number of supporting and fixing devices, a number of trays 5, and a mechanical drive mechanism;

[0059] Several trays 5 are connected to the carrying tray 1 through several supporting and fixing devices, and the mechanical drive mechanism is used to drive the carrying tray 1 and the trays 5 to rotate.

[0060] Preferably, specifically, the supporting and fixing device includes: an intermediate positioning column 6 , the upper end of which is fixed at the center of the bottom of the tray 5 , and the lower end of the intermediate positioning column 6 is rotatably connected to the carrying large plate 1 .

[0061] Preferably, the middle positioning column 6 is connected to the bottom of the tray 5 through a high-temperature-resistant and wear-resistant connector (a connector made of a high-temperature-resistant and wear-resis...

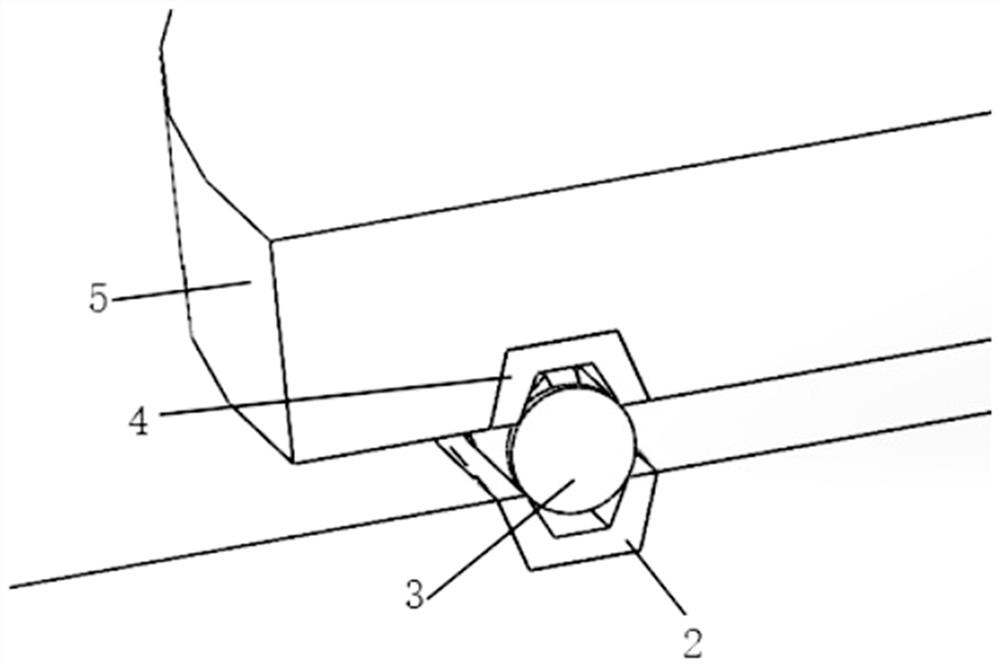

example 1

[0063] In Example 1, the ball 3 is used to support the tray 5, and the middle positioning post 6 plays a role of fixing; while in this embodiment, the middle positioning post 6 plays the role of supporting and fixing, and the ball 3 is removed.

[0064] The beneficial effect of the above-mentioned technical solution is: in this embodiment, the method of suspending the tray is replaced by the mechanical method driven by gears and the middle positioning column is opened, so as to overcome the problems caused by the unstable and uneven air flow during rotation. Friction and collision of the load-carrying plate will cause cracks, and it can also avoid the direct contact between the coating and the moving parts to expose the graphite substrate, which will be infiltrated by corrosive gases, causing the graphite to collapse and cause the tray components to be scrapped, thereby effectively improving the high temperature resistant ceramic coating. Layer graphite tray assembly life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com