Cleaning device for range hood, fan cleaning device and range hood

A technology for cleaning devices and range hoods, which is applied to the components of pumping devices for elastic fluids, cleaning methods using liquids, and oil fume removal, etc. Weak strength and other problems, to achieve the effect of not affecting the performance of the fan, full coverage and efficient cleaning, and small modification of the original structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

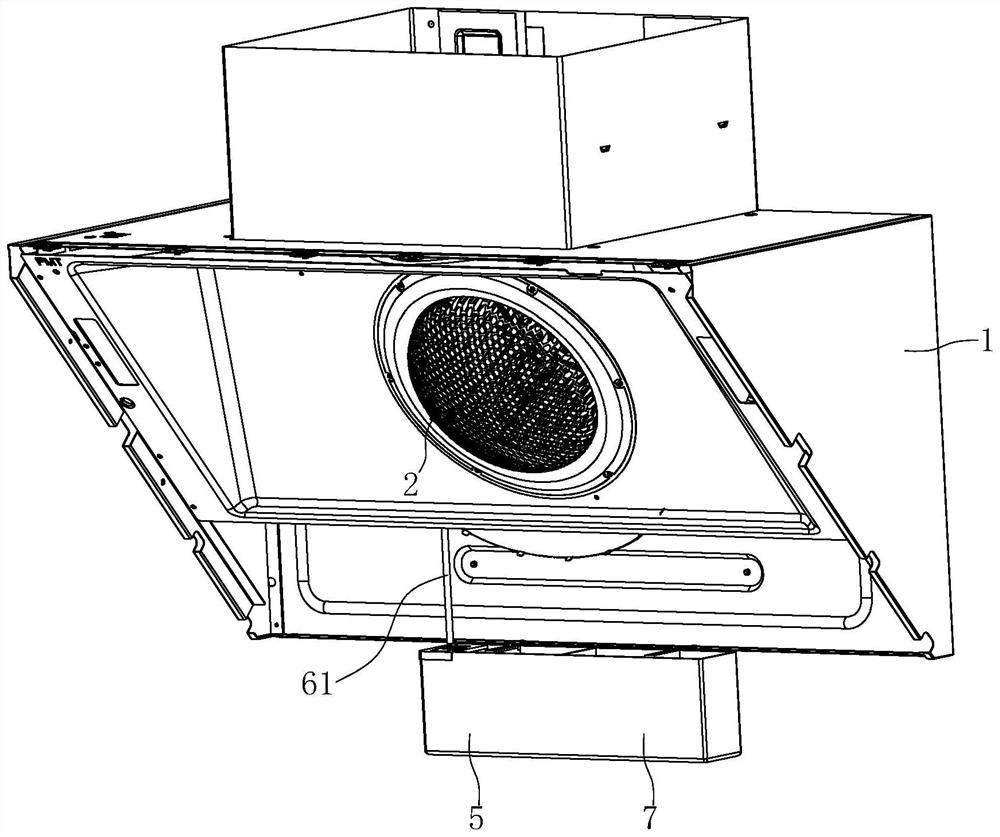

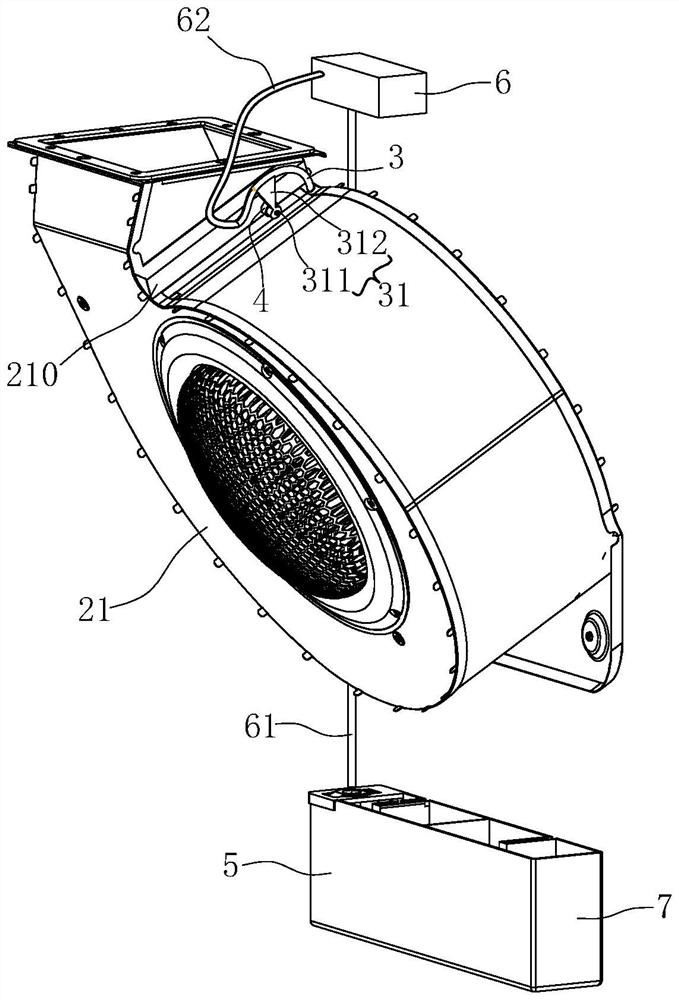

[0076] Such as Figure 1 to Figure 12 Shown is the first preferred embodiment of the range hood of the present invention. The range hood includes a casing 1 , a fan 2 , a cleaning medium supply part 3 , a driving device 4 , a water tank 5 , a steam generator 6 , a water receiving box 7 and a sensor 8 .

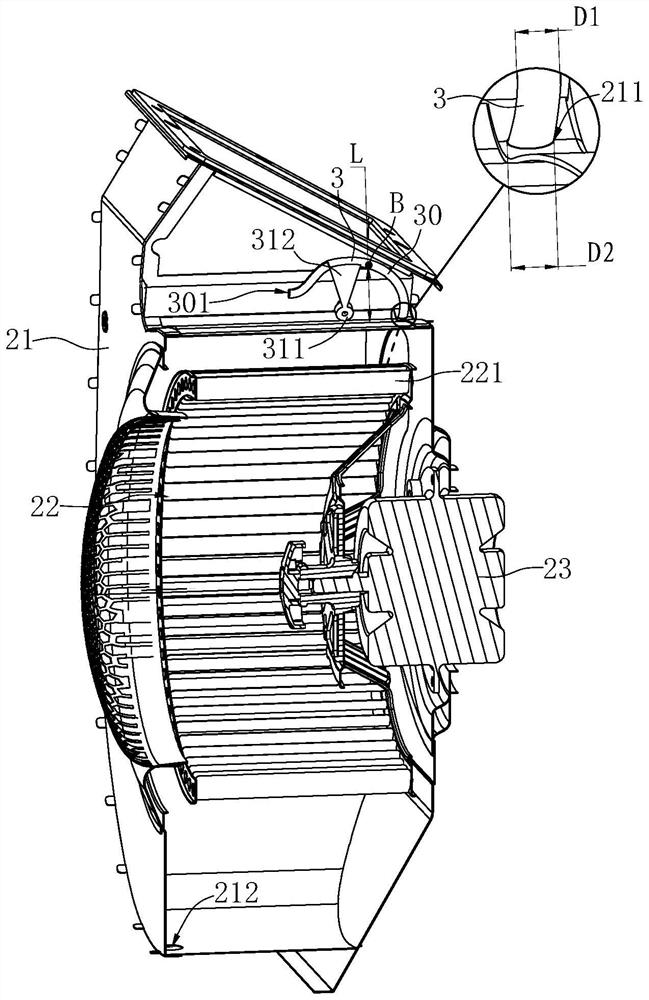

[0077] Wherein, the fan 2 is arranged in the casing 1 and includes a volute 21 , an impeller 22 arranged in the volute 21 and a driving member 23 for driving the impeller 22 to rotate. Such as image 3 As shown, the ring wall of the volute 21 is located at the position of the volute tongue 210 to open a relief hole 211, and the bottom of the volute 21 is provided with a drain hole 212; the impeller 22 is arranged at intervals along the circumferential direction with a plurality of axially extending Blade 221.

[0078] The cleaning medium supply part 3 is tubular, and has a front section, a middle section and a rear section successively along the flow direction of the cleani...

Embodiment 2

[0177] Such as Figure 13 Shown is the second preferred embodiment of the range hood of the present invention. The difference with Example 1 is:

[0178] In this example, if Figure 13 As shown, in the non-working state, the end face of the piercing portion 30 faces the relief hole 211, and the outlet 302 of the piercing portion 30 is located on the adjacent side wall of the end face, so that in the non-working state, the volute inside the The airflow of 21 is no longer easy to rush to the outlet 302 of the piercing part 30 through the relief hole 21 to cause its blockage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com