Method for determining uniaxial compressive strength damage of red mudstone after dry-wet cycle

A technology of uniaxial compressive strength and dry-wet cycle, which is applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, instruments, etc., and can solve the problems of long and cumbersome test periods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

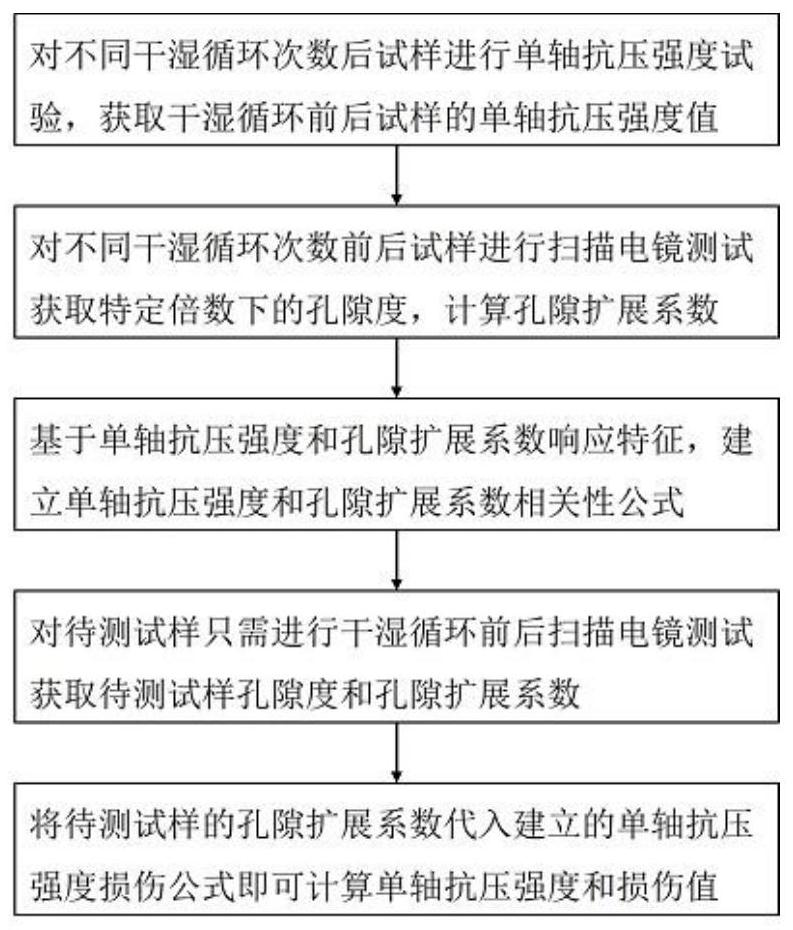

Method used

Image

Examples

Embodiment 1

[0028] The present invention carries out technical verification by the method of test, and concrete test process is as follows.

[0029] Uniaxial compressive strength test of red bed mudstone under dry-wet cycle:

[0030] On-site sampling and indoor sample preparation and dry-wet cycle test are carried out according to the specifications, and the uniaxial compressive strength test is carried out on the samples that have completed the dry-wet cycle. The loading rate is controlled by the formula, and the loading rate is set at 0.12mm / min, and the loading rate is maintained until the mudstone sample is destroyed.

[0031] Analysis of uniaxial compressive strength test results:

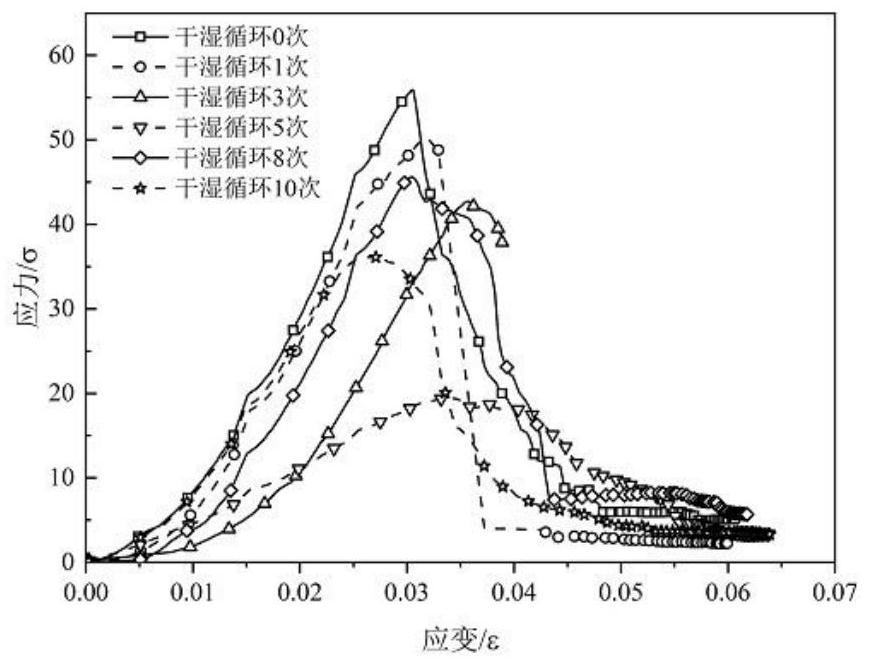

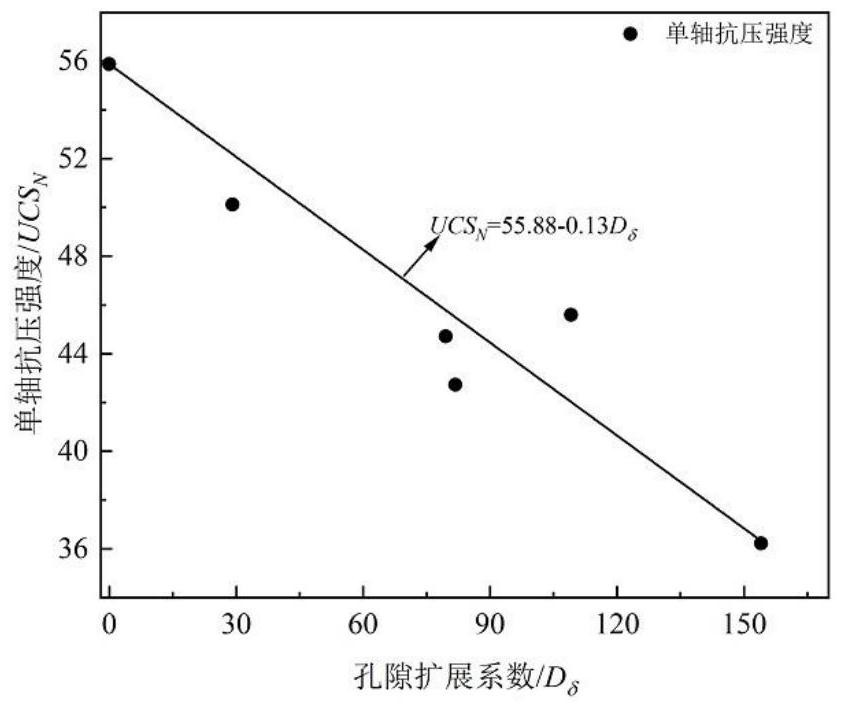

[0032] The results of uniaxial compression test of red bed mudstone under the action of dry-wet cycle are shown in figure 2 . From figure 2 It can be seen from the figure that the uniaxial compressive strength of the red bed mudstone decreases with the increase of the number of dry-wet cycles; under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com