Intelligent manufacturing order management method and system

A technology for order management and intelligent manufacturing, applied in manufacturing computing systems, data processing applications, sales/lease transactions, etc., can solve problems such as the lack of effective methods for collaborative production, backlogs of orders in production enterprises, idle production equipment, etc., to avoid production Effects of wasting resources, improving satisfaction, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

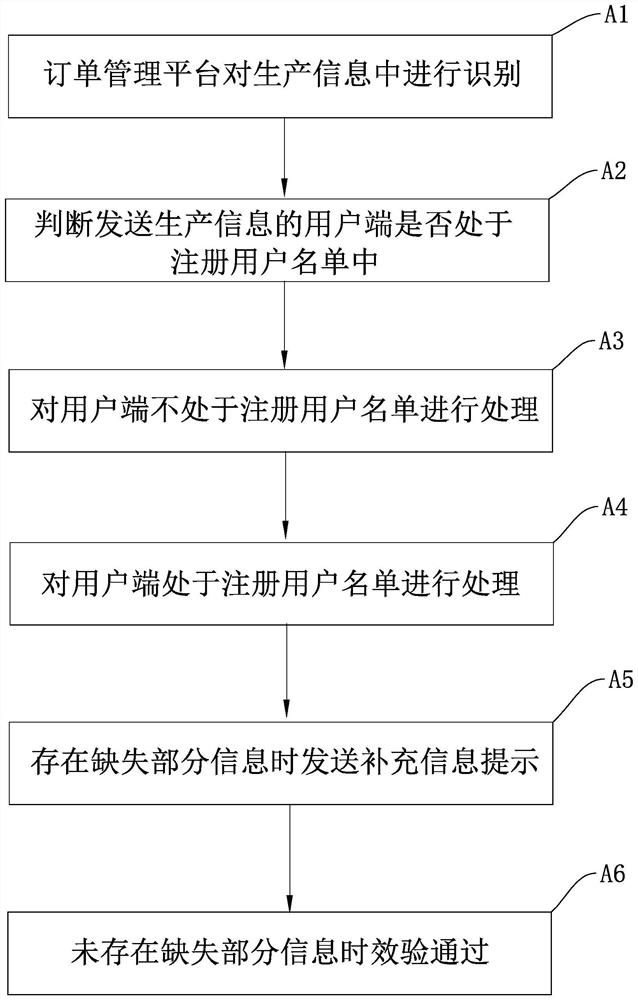

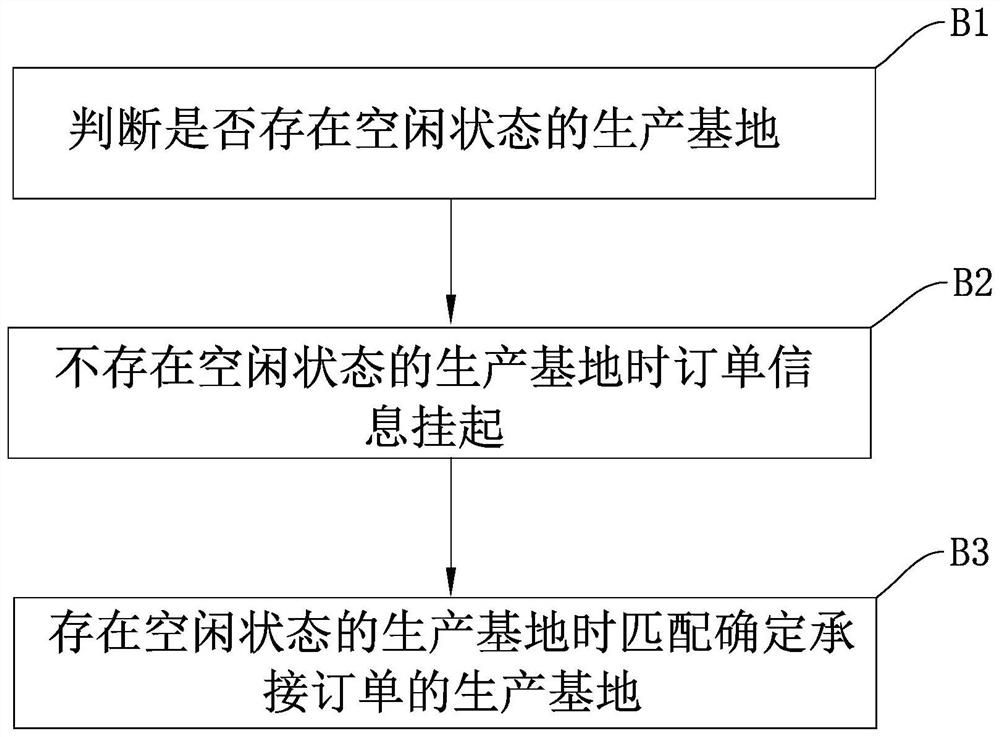

[0074] The following is attached Figure 1-7 The application is described in further detail.

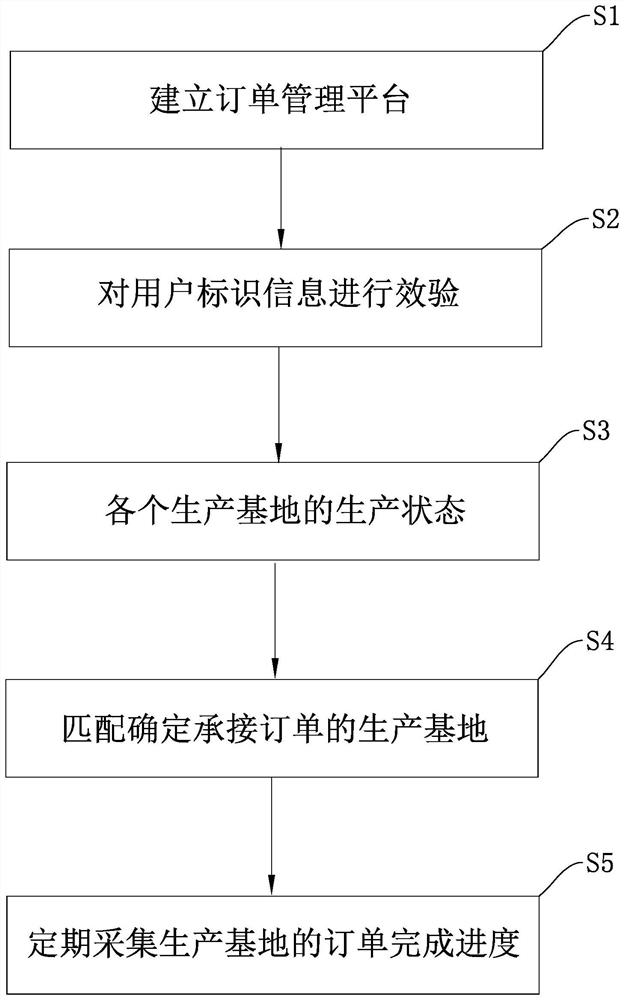

[0075] The embodiment of the present application discloses a method for intelligent manufacturing order management. refer to figure 1 , an intelligent manufacturing order management method, comprising the following steps:

[0076] S1. Establish an order management platform: establish an order management platform to receive production information sent by the client, the production information includes user identification information and order information, and the order information includes product information, product production quantity information, delivery location information, Delivery time information, the product information includes product type information, production process rules, product rule information, technical knowledge rules, machine tool identifier and product name information;

[0077] Clients are devices capable of sending and storing data and having computing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com