High-reliability rivet type electrical contact, forming equipment and forming method

A technology for forming equipment and electric contacts, which is applied to circuits, electric switches, contact materials, etc., can solve the problems of reducing the life of electric contacts, high contact surface resistance, and welding stickiness, etc., so as to improve service life and increase Surface area, the effect of improving the bonding force of silver and copper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

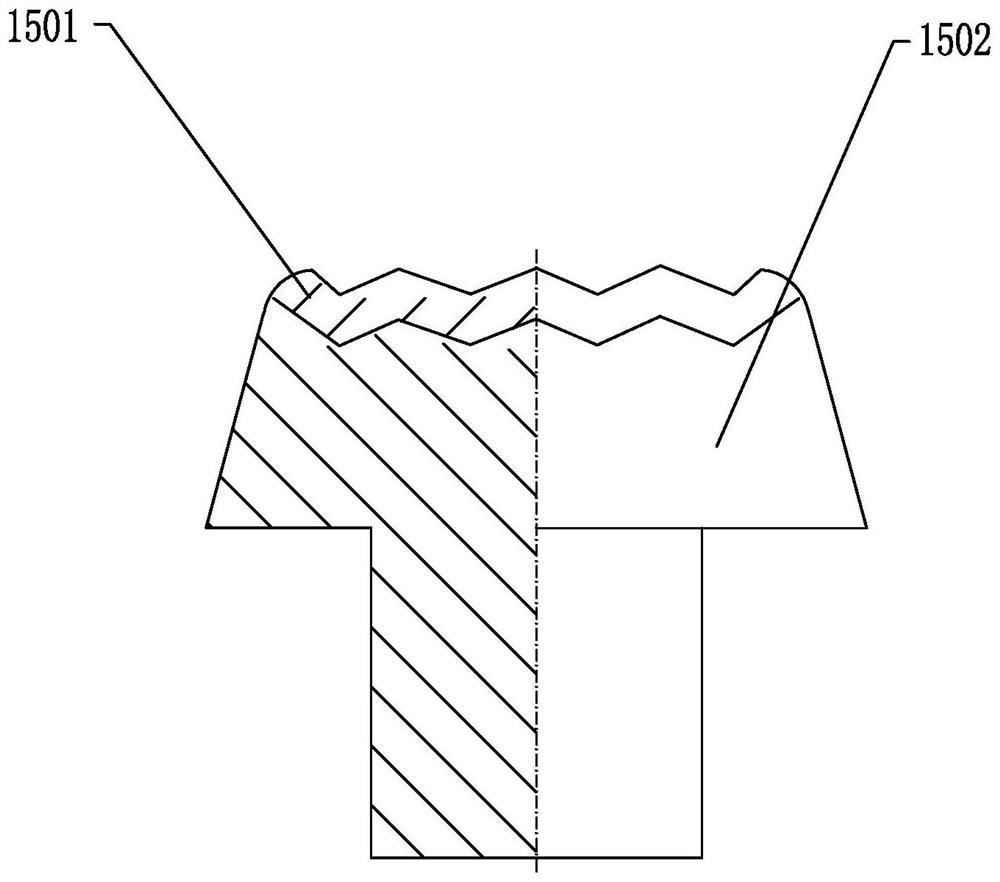

[0073] like figure 1 As shown, a high-reliability rivet-type electrical contact, the rivet-type electrical contact is a composite electrical contact formed by silver alloy layer 1501 and copper base layer 1502; the silver alloy layer 1501 is far away from the copper base layer 1502 Grooves are provided on one side surface.

[0074] Preferably, the groove is in the shape of a "W" pattern.

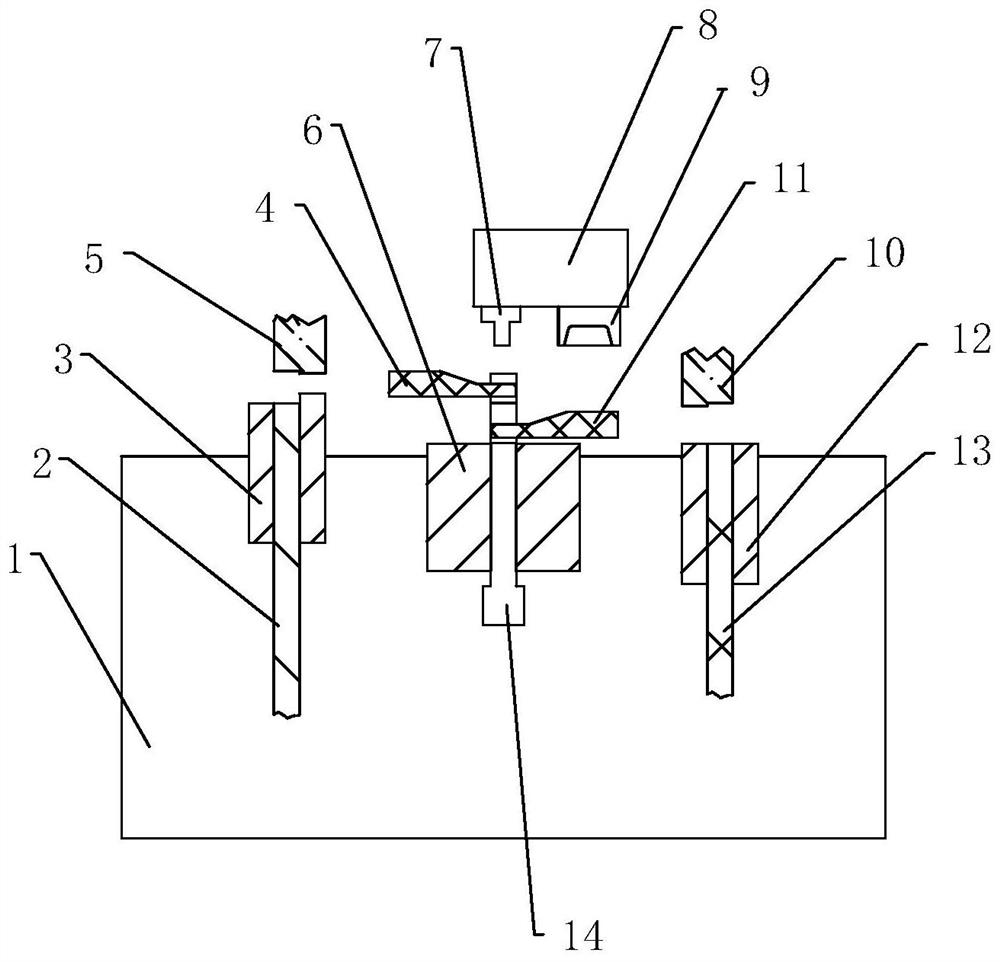

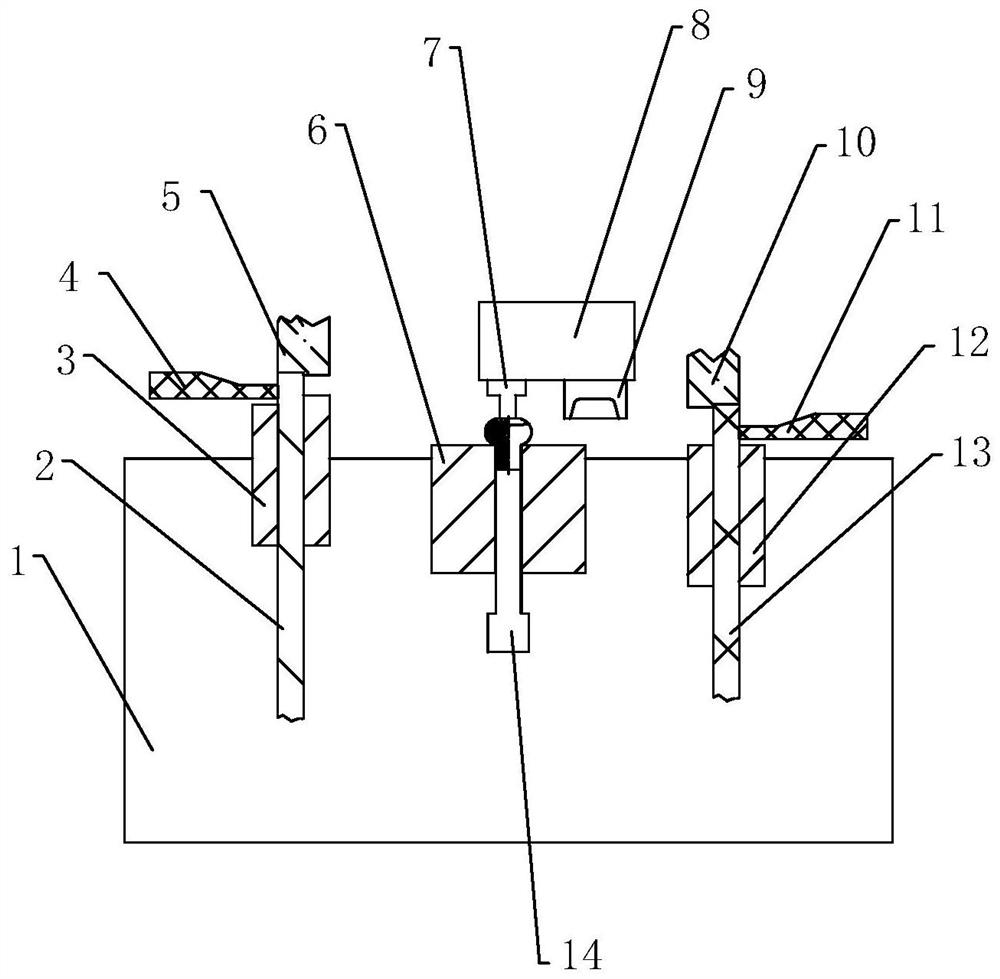

[0075] like Figure 2-6 As shown, the molding equipment for molding the above-mentioned high-reliability rivet-type electrical contacts is provided, including,

[0076] Formwork 1, said formwork 1 is provided with forming bottom mold 6, forming bottom needle 14 positioned in forming bottom mold 6, silver wire conduit 3 for conveying silver alloy wire 2, copper wire for conveying copper wire 13 wire conduit 12;

[0077] Movable mold frame 8, described movable mold frame 8 is provided with primary forming mold 7 and final forming mold 9, and described primary forming mold 7 is used for pre...

Embodiment 2

[0091] In the rivet-type electrical contact of this embodiment, on the basis of Embodiment 1, the contact surface of the silver alloy layer 1501 and the copper base layer 1502 is concave-convex.

[0092] In this embodiment, the contacting surface of the silver alloy layer 1501 and the copper base layer 1502 is concave-convex with a "W" pattern.

[0093] Compared with the molding equipment of Example 1, the molding equipment used to manufacture the rivet-type electrical contacts of this embodiment, such as Figure 8 As shown, in this embodiment, a second embossment 1001 is provided on the end surface of the copper wire retaining rod 10 above the copper wire conduit 12, and the copper wire cutter 11 cooperates with the second embossing 1001 of the copper wire retaining rod 10 to cut off Copper wire 13 forms a groove on the upper end surface of the copper material segment; as Figure 9 As shown, a third emboss 301 is provided on one end surface of the silver wire conduit 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com