Reverse conducting IGBT

A reverse-conducting, conductive-type technology, applied in semiconductor devices, diodes, electrical components, etc., can solve the problems of increasing IGBT saturation voltage, difficulty in balancing, and conflict, and achieve charge balance, saturation voltage drop optimization, and good emission. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

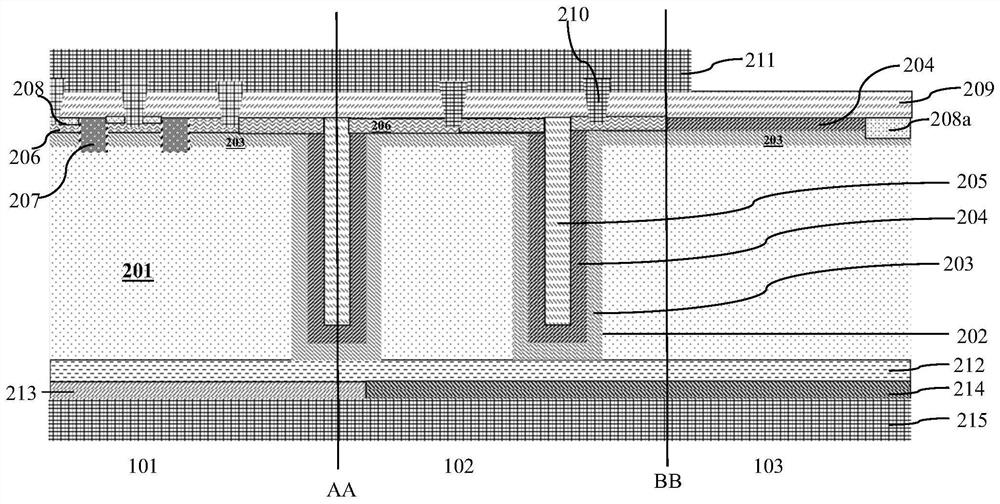

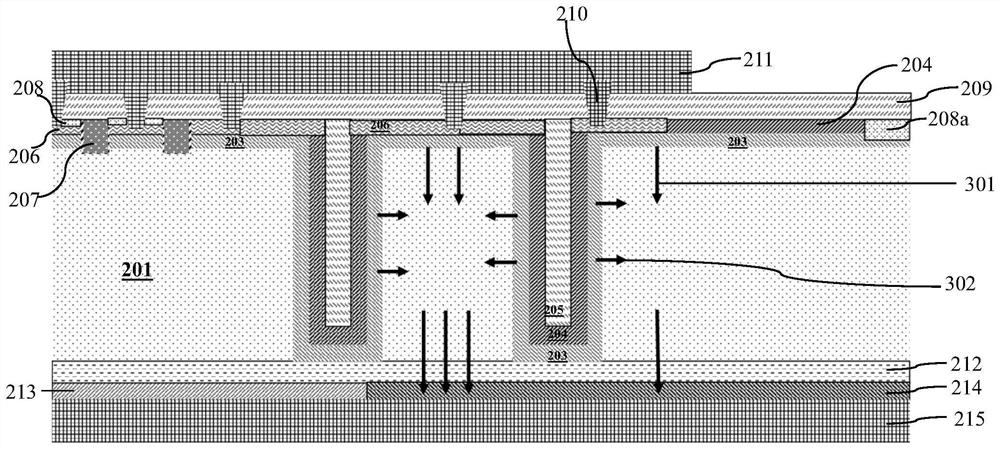

[0051] like figure 1 Shown is a schematic structural diagram of the reverse conduction IGBT of the embodiment of the present invention; the reverse conduction IGBT of the embodiment of the present invention includes an antiparallel IGBT and an FRD.

[0052] In the lateral direction, the formation region 101 of the IGBT and the formation region 102 of the FRD are adjacent to and separated from each other. figure 1 In the figure, the IGBT formation area 101 is located on the left side of the line AA; the FRD formation area 102 is located between the line AA and the line BB, and the right side of the line BB is the termination area 103 .

[0053] A drift region 201 doped with the first conductivity type and a field stop layer 212 are formed in the formation region 101 of the IGBT and the formation region 102 of the FRD; the field stop layer 212 is located at the bottom of the drift region 201 and The doping concentration of the field stop layer 212 is greater than the doping con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com