Lubricating oil furfural refining device based on partition plate tower and technology thereof

A furfural refining and lubricating oil technology, which is applied in the petrochemical field, can solve the problems of complex refining process and large number of equipment, and achieve the effects of reducing fluid flow resistance, compact equipment and convenient automation control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

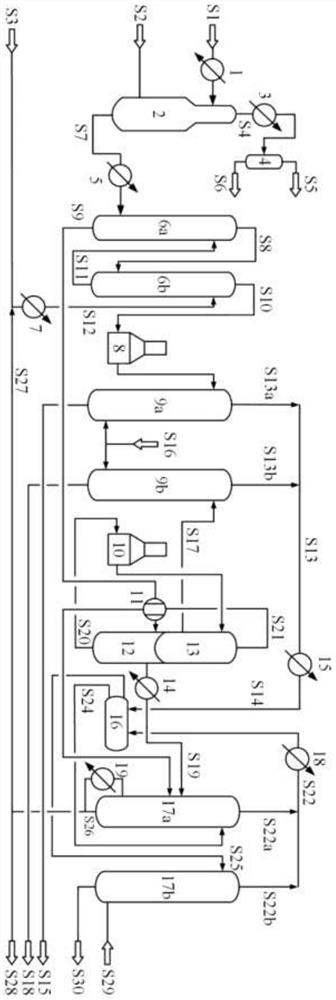

[0043] In the lubricating oil furfural refining unit with an annual output of 500,000 tons of light lubricating oil in a petrochemical company, the original unit is a conventional lubricating oil furfural refining unit, which adopts a double-tower countercurrent extraction process. The process flow chart is shown in figure 1 , the composition analysis of raw oil is shown in Table 1.

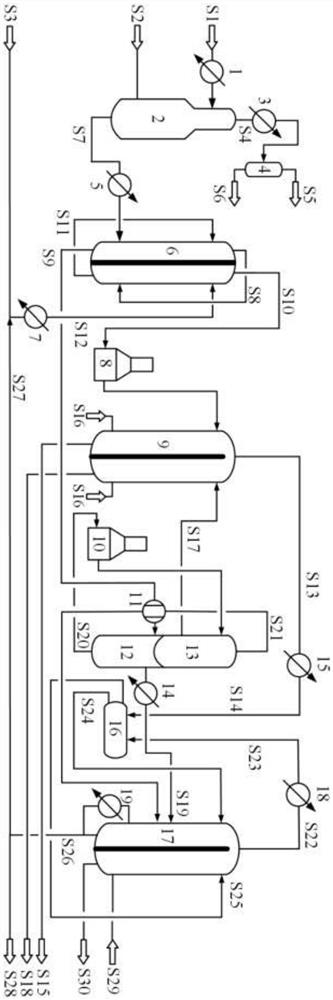

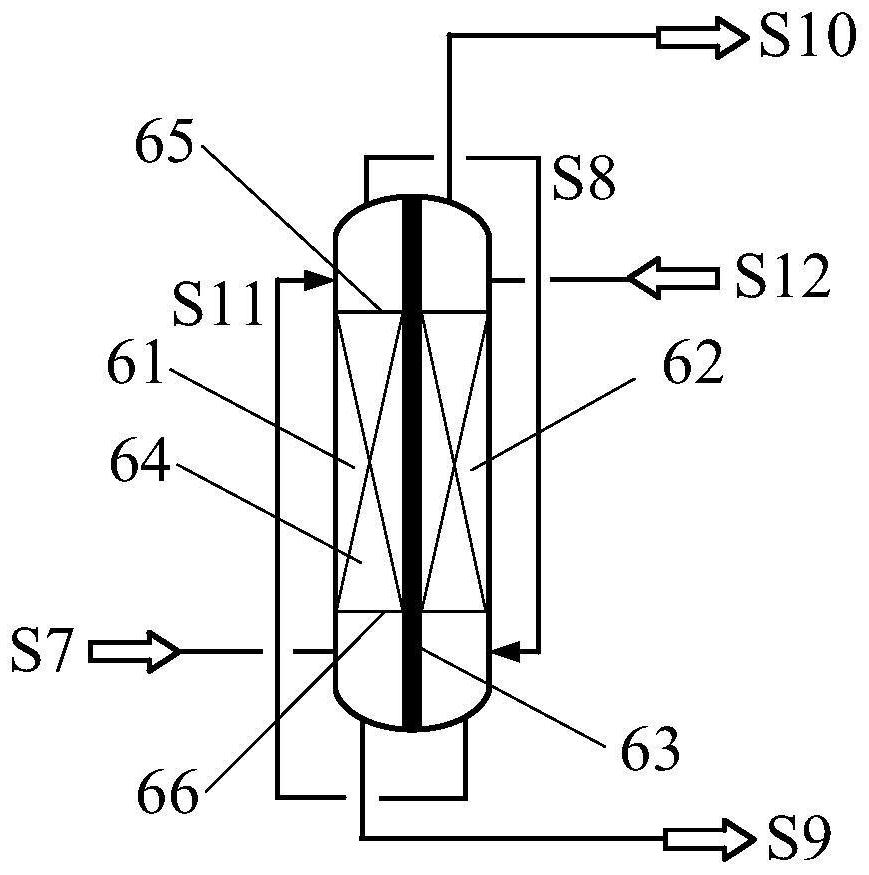

[0044] Modified devices such as figure 2 as shown, figure 1 The first-stage extraction tower 6a and the second-stage extraction tower 6b of the Zhongyuan process are integrated into figure 2 The stripping tower 6 of existing technology, the raffinate stripping tower 9a of original technology and extract liquid stripping tower 9b are integrated into the stripping tower 9 of existing technology, the furfural drying tower 17a of original technology and furfural dehydration The tower 17b is integrated into the furfural dehydration drying tower 19 of the existing technology. The extraction tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com