High-hardness plate trepanning and edging system

A high-hardness, hole-grinding technology, applied in the direction of grinding machines, grinding drive devices, stone processing equipment, etc., can solve the problems of high processing cost, low efficiency, and affecting the popularization of rock slab decoration, so as to reduce processing costs and ensure processing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0053] In describing the present invention, it should be understood that the terms "center", "longitudinal", "transverse", "length", "width", "thickness", "upper", "lower", "front", " Back", "Left", "Right", "Vertical", "Horizontal", "Top", "Bottom", "Inner", "Outer", "Clockwise", "Counterclockwise", "Axial", The orientation or positional relationship indicated by "radial", "circumferential", etc. is based on the orientation or positional relationship shown in the drawings, and is only for the convenience of describing the present invention and simplifying the description, rather than indicating or implying the referred device or element Must be in a particular orientation, be constructed in a particular orientation, and operate in a particular orientation, and therefore should not be construed as limiting the invention.

[0054] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in d...

specific Embodiment 1

[0056] A high-hardness plate opening and edging system, including:

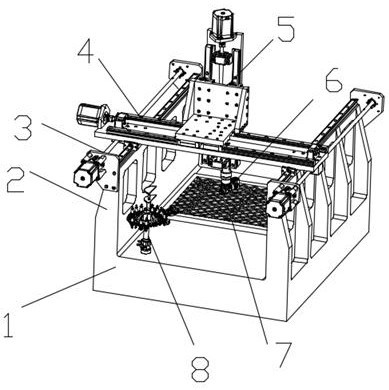

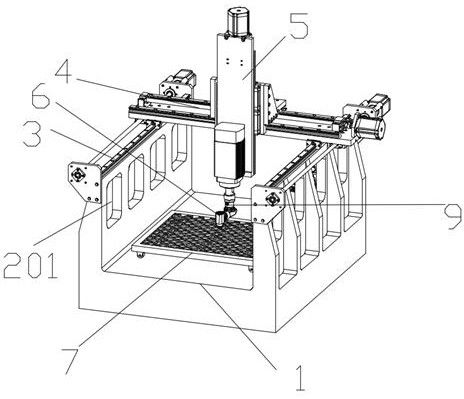

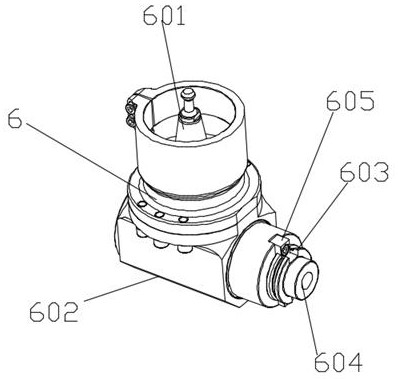

[0057] - The hole edging device is fixed on the lower end of the Z-axis motion assembly 5 of the CNC gantry milling machine. The CNC gantry milling machine is provided with a base 1, and a plurality of columns 2 are arranged on both sides of the base 1, and adjacent columns 2 are provided. There is an observation window 201, and the top of the column 2 is provided with a Y-axis motion assembly 3, and two parallel and horizontal Y-axis motion assemblies 3 are connected together through an X-axis motion assembly 4, and the middle part of the X-axis motion assembly 4 is vertically provided with The Z-axis motion assembly 5, the hole edging device is provided with a main shaft quick change device 6, the main shaft quick change device 6 is provided with an inner main shaft 604 and an outer main shaft 603, and the inner main shaft 604 is fixed by the inner main shaft connecting shaft 609 and the second bevel gear 60...

specific Embodiment 2

[0061] On the basis of the specific embodiment 1, the first controller provides an activation signal for the second controller, and the second controller controls the spindle quick change device to drive the spherical milling cutter to process a spherical concave surface, which can avoid repeated setting of the control spindle Rotate the program, reduce the conflict between subprograms, and reduce the failure rate of machine tool programs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com