Composite board structure and manufacturing method thereof

A composite sheet and manufacturing method technology, applied in the direction of copying/marking method, telephone structure, manufacturing auxiliary device, etc., can solve the problems of low dyne value, inability to apply mobile phone back cover products, and poor bonding force of printing glue, etc., to achieve Meet the performance requirements, meet the appearance requirements, and ensure the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

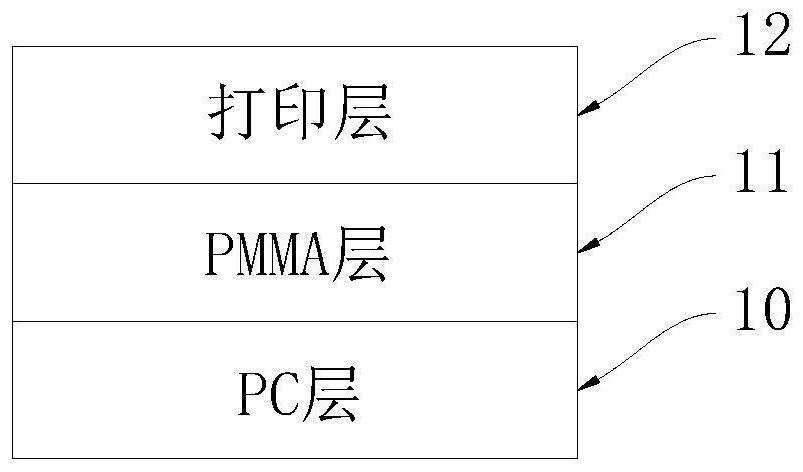

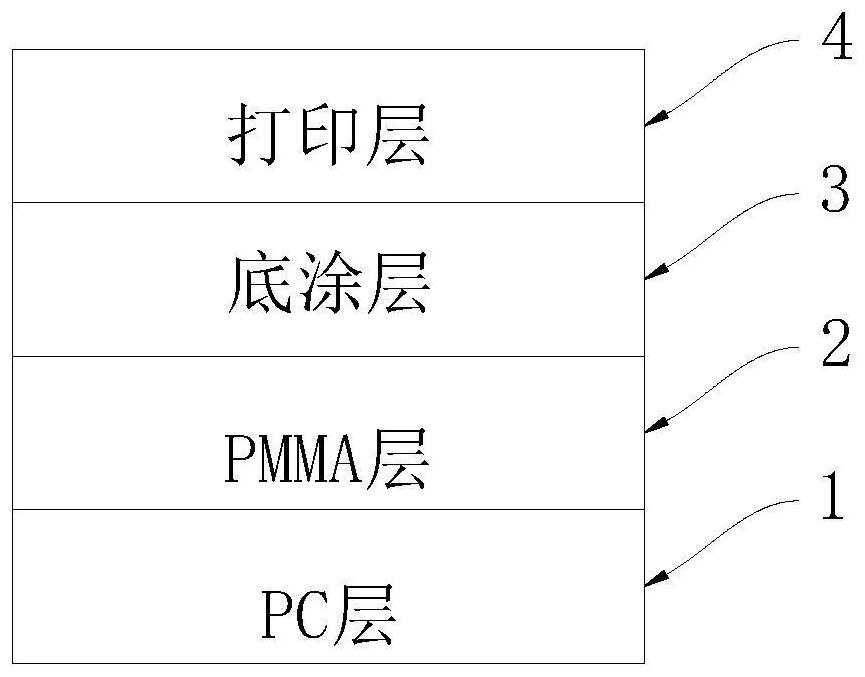

[0018] The invention discloses a composite plate structure, please refer to figure 2 , which includes a PC layer 1, the top of the PC layer 1 is provided with a PMMA layer 2, the top of the PMMA layer 2 is coated with a primer layer 3, and the top of the primer layer 3 is printed with a print layer 4 .

[0019] During the manufacturing process of the above structure, the acrylic layer of the composite board is first coated with a primer layer, and then printed. Compared with the prior art, the present invention first adds the primer glue on the acrylic surface as a carrier, and then prints on the primer layer, which effectively ensures the adhesion to the printing layer, and can meet the needs of the back cover of the mobile phone. The appearance requirements also better meet the performance requirements of the product.

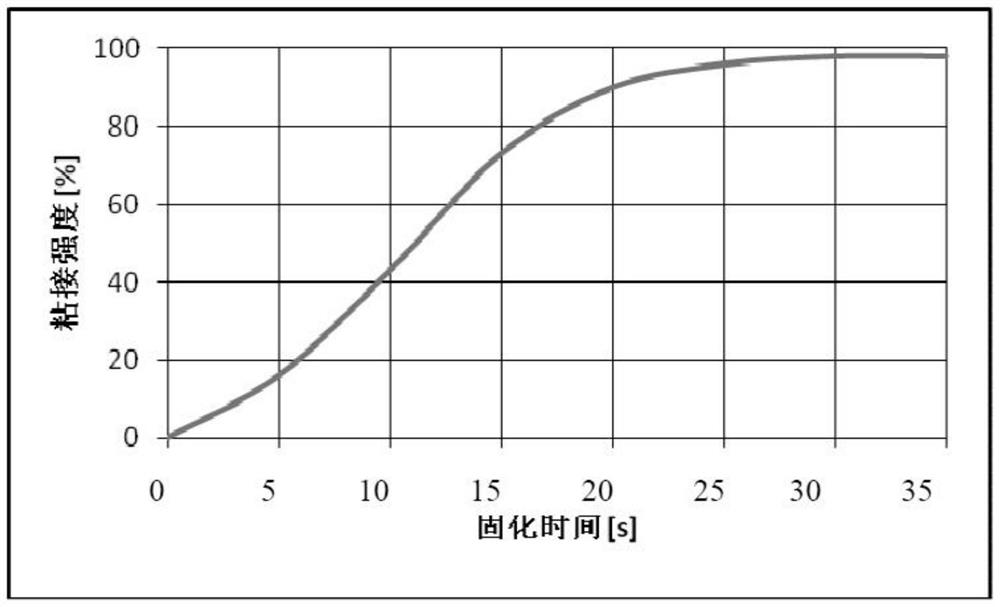

[0020] In this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com