Deep-sea soft robotic fish propelled by tail fin

A robotic fish and tail fin technology, applied in non-rotating propulsion elements, motor vehicles, special-purpose ships, etc., can solve the problems of driving efficiency and cruise stability to be improved, and achieve excellent deep-sea pressure adaptive ability, flexible movement, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

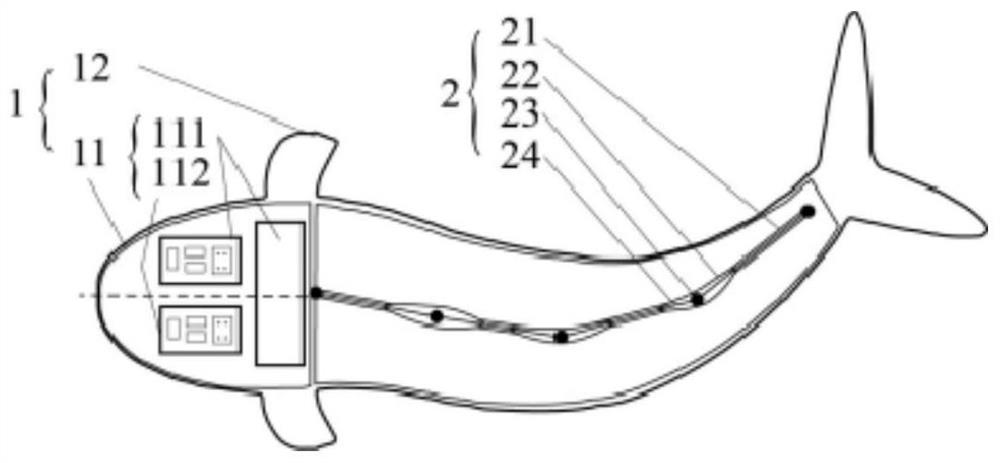

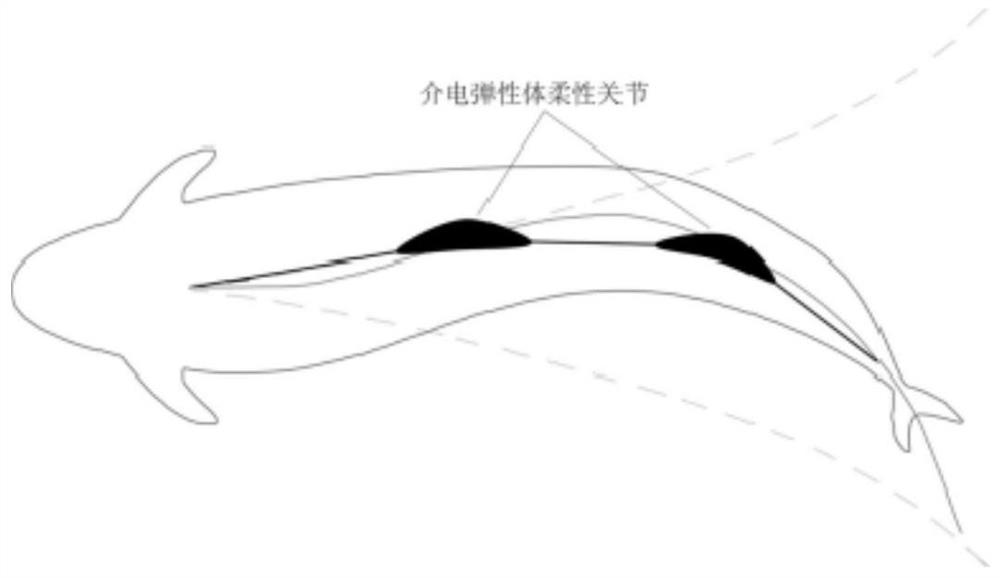

[0031] Such as image 3 As shown, a deep-sea mollusc robotic fish propelled by a caudal fin in this embodiment is composed of two dielectric elastomer flexible joints connected in series; each dielectric elastomer flexible joint includes a support frame 21, a dielectric elastomer film 22, a flexible Electrodes 23 and wires; the dielectric elastomer film 22 is stretched on the corresponding hollow of the support frame 21, the flexible electrodes 23 are coated on the dielectric elastomer film 22, and the wires 24 connect each flexible electrode to the energy source Module 111.

[0032] The control module 112 continuously adjusts the voltage boosting module and the voltage stabilizing module in the energy module 111 through a pulse width modulation (PWM) method, and outputs a constantly changing voltage to the propulsion module; the propulsion module receives the constantly changing voltage from the energy module 111, That is, the two dielectric elastomer flexible joints are sub...

Embodiment 2

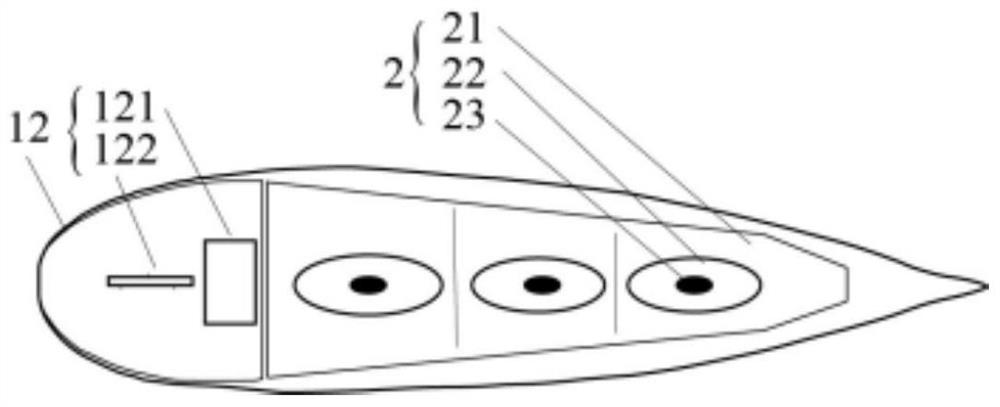

[0036] Such as Figure 4 As shown, a tail fin propelling deep-sea mollusc robot fish provided in this embodiment is composed of three dielectric elastomer flexible joints connected in series; each dielectric elastomer flexible joint includes a support frame 21, a dielectric elastomer film 22, a flexible Electrodes 23 and wires; the dielectric elastomer film 22 is stretched on the corresponding hollow of the support frame 21, the flexible electrodes 23 are coated on the dielectric elastomer film 22, and the wires 24 connect each flexible electrode to the energy source Module 111.

[0037] The control module 112 continuously adjusts the voltage boosting module and the voltage stabilizing module in the energy module 111 through a pulse width modulation (PWM) method, and outputs a constantly changing voltage to the propulsion module; the propulsion module receives the constantly changing voltage from the energy module 111, That is, the three dielectric elastomer flexible joints a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com