Vacuum degree keeping structure of reaction flywheel

A reaction flywheel, vacuum technology, applied in the direction of packaging, sealing and locking equipment under vacuum/special atmosphere, can solve the problems of short vacuum holding time and difficult process, and achieve improved sealing time, less process difficulty, lower slowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

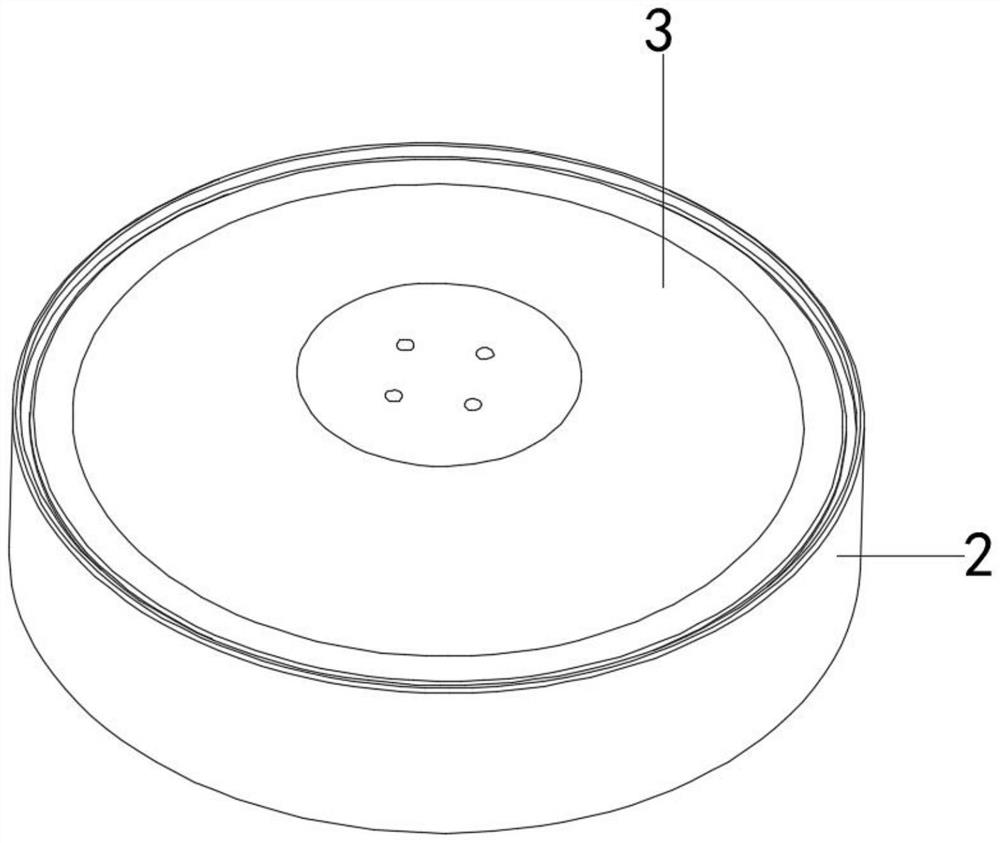

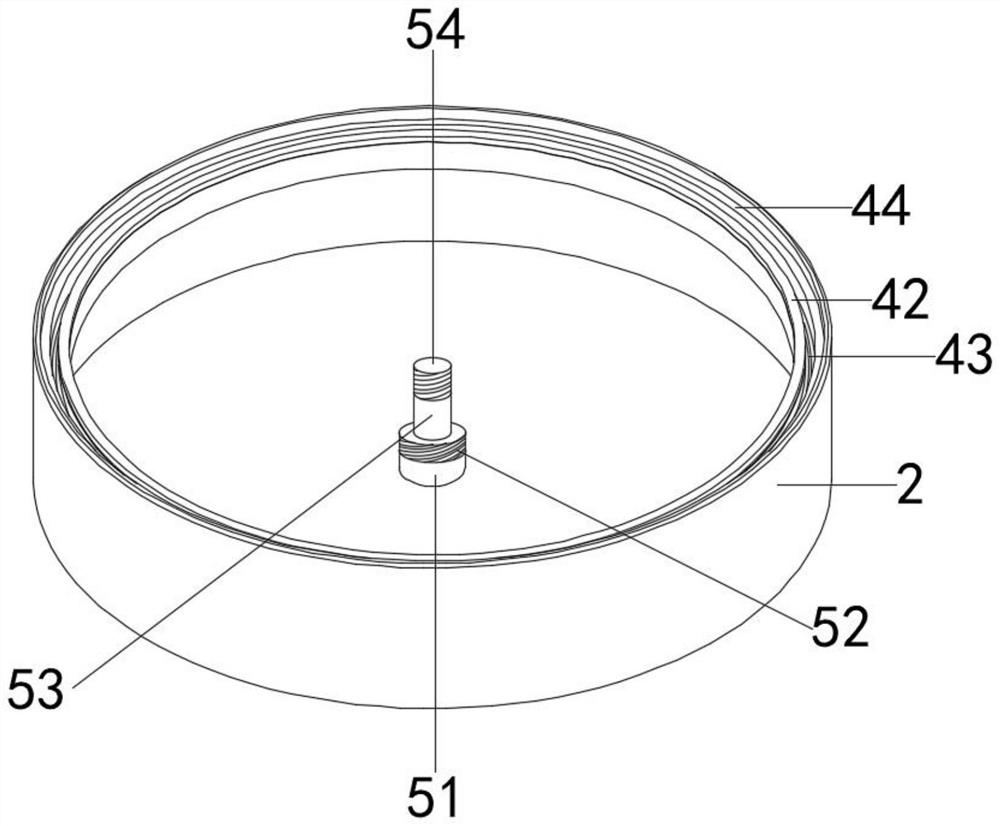

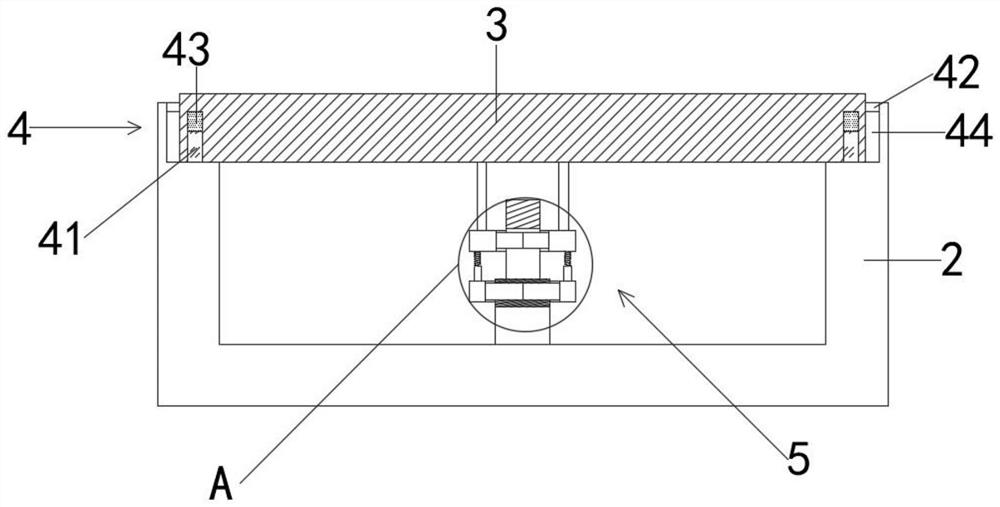

[0029] The present invention provides a reaction flywheel vacuum degree maintaining structure, which has the advantage of improving sealing performance, please refer to Figure 1-Figure 6 , including a base 2 and a sealing cover 3, the base 2 and the sealing cover 3 are connected through a sealing component 4, and then fixed through a connecting component 5.

[0030] The sealing assembly 4 includes a clamping plate 41, a first clamping groove 42, a rubber sealing ring 43, epoxy glue 44 and a second clamping groove 45. The clamping plate 41 is fixedly installed on the inner side of the top of the base 2, and the clamping plate 41 and the The top of the base 2 forms a first engagement groove 42, and the inner wall of the bottom end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com