Cutting and plate-breaking process for hot glass on production line for manufacturing rolled glass

A production line and glass plate technology, which is applied to glass cutting devices, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of wasting energy, etc., and achieve the effect of accurate size, straight cutting track, and neat cutting edges without chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] On the 250t / d one-kiln two-line calendering production line, the original plate width is 2200mm, the thickness is 3.2mm glass, and the designed plate size after online cutting is 1960×994mm.

[0051] In the cutting and breaking process of hot glass in the production line of rolling glass in this embodiment, the high temperature is 500-650°C, and the process specifically includes the following steps:

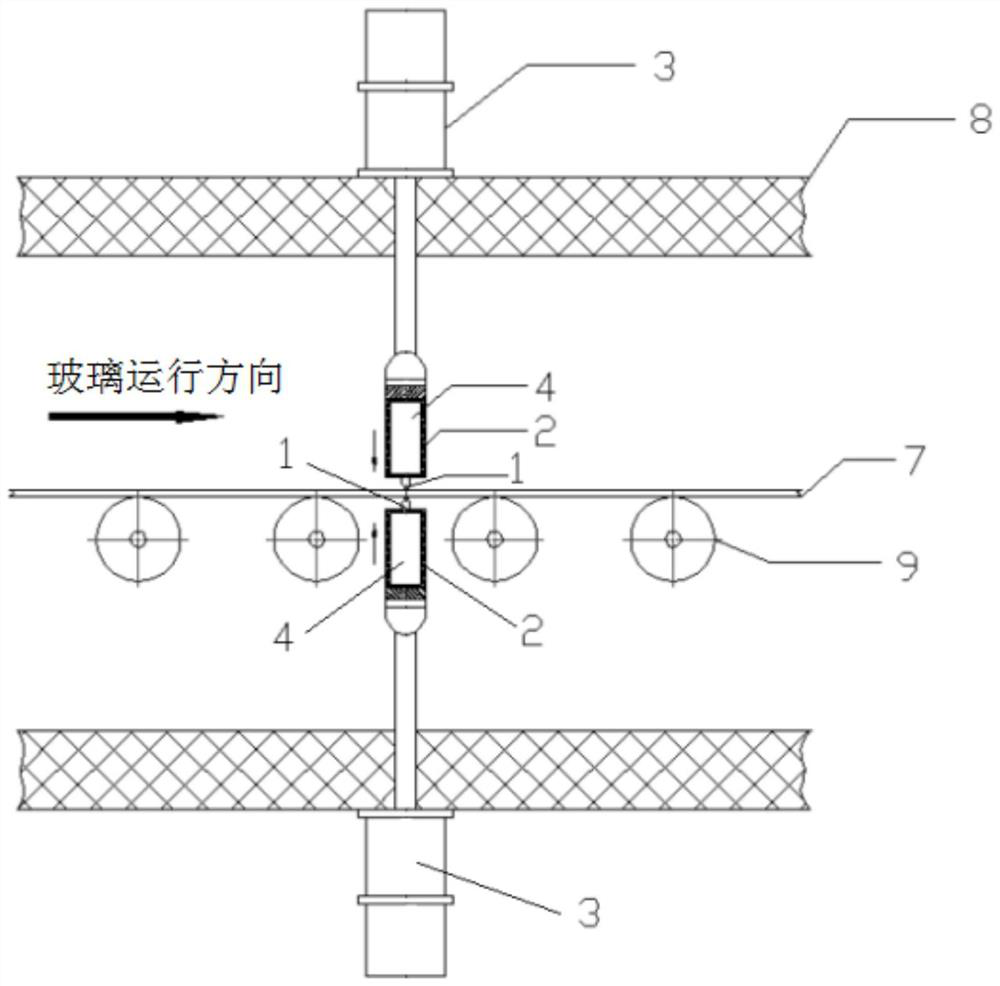

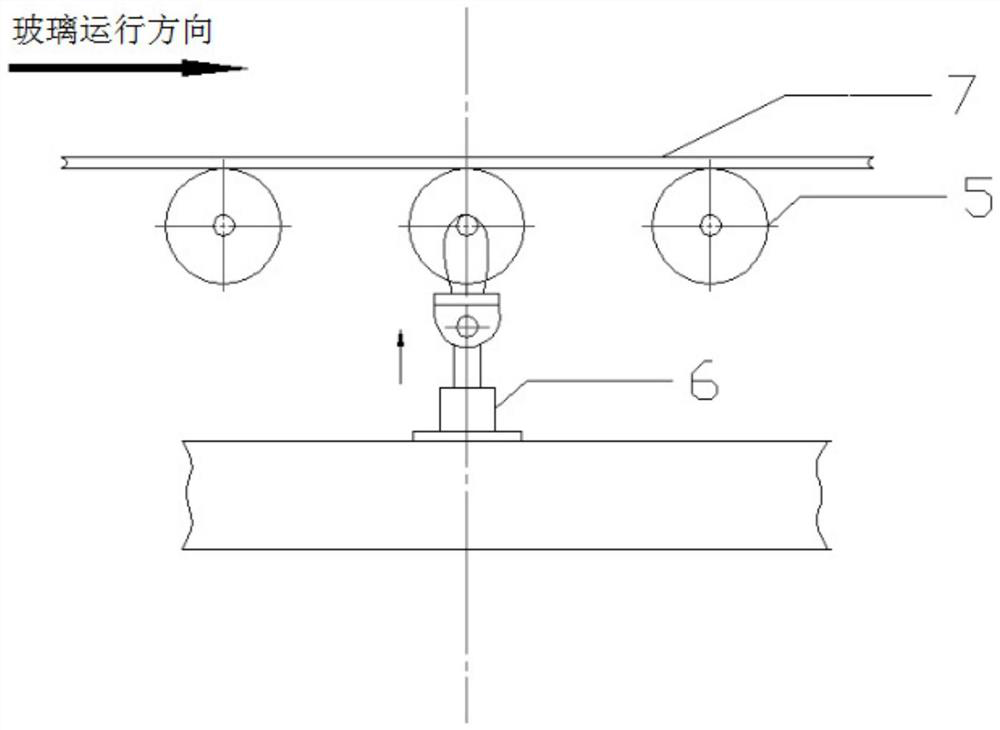

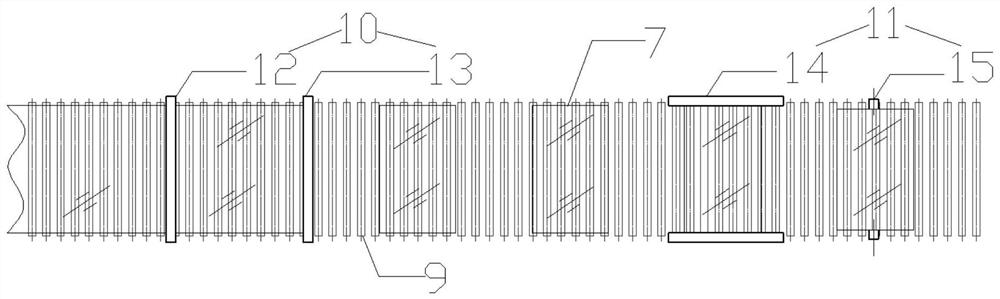

[0052] (1) When producing 3.2mm rolled glass, the speed of the main line glass plate is 10.5m / min, and the cutting is set according to the finished plate size of 1960×994mm. When the high temperature glass ribbon 7 reaches the cutting size, it is placed by the control center Transverse cutting device 12 at the entrance of area A of the annealing kiln sends a signal. The horizontal cutting device 12 is arranged on both sides of the annealing kiln shell 8. The pneumatic lifting device 3 is located outside the annealing kiln shell 8. The pneumatic lifting device 3 cuts across ...

Embodiment 2

[0061] In the 250t / d one-kiln two-line calendering production line, the original plate width is 1900mm. When producing 3.2mm glass, the main line glass plate speed is 12.4m / min, and the designed cutting plate size is 1652×994mm.

[0062] In the cutting and breaking process of hot glass in the production line of rolling glass in this embodiment, the high temperature is 500-650°C, and the process specifically includes the following steps:

[0063] (1) In the process of producing 3.2mm rolled glass, the cutting is set according to the finished plate size of 1652×994mm. When the high temperature glass ribbon 7 reaches the cutting size, it is cut from the control center to the transverse direction placed at the entrance of the annealing kiln A area. The board device 12 sends the signal, the transverse cutting device 12 is arranged on both sides of the annealing kiln shell 8, the pneumatic lifting device 3 is located outside the annealing kiln shell 8, the pneumatic lifting device 3 ...

Embodiment 3

[0072] On the 250t / d one-kiln two-line calendering production line, the original plate width is 1800mm. When producing 3.2mm glass, the main line glass plate speed is 13.1m / min, and the designed cutting plate size is 1582×810mm.

[0073] In the cutting and breaking process of hot glass in the production line of rolling glass in this embodiment, the high temperature is 500-650°C, and the process specifically includes the following steps:

[0074] (1) In the process of producing 3.2mm rolling glass, the cutting is set according to the size of the finished plate surface of 1582×810mm. When the high temperature glass ribbon 7 reaches the cutting size, it is cut from the control center to the cross section placed at the entrance of area A of the annealing kiln. The board device 12 sends the signal, the transverse cutting device 12 is arranged on both sides of the annealing kiln shell 8, the pneumatic lifting device 3 is located outside the annealing kiln shell 8, the pneumatic lifti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com