ABS (Acrylonitrile Butadiene Styrene) plastic with electromagnetic shielding function and process thereof

A technology of ABS plastic and electromagnetic shielding, which is applied to the device and coating of the surface coating liquid, which can solve the problems of artificial position placement, scratching, inconvenience of ABS plastic, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

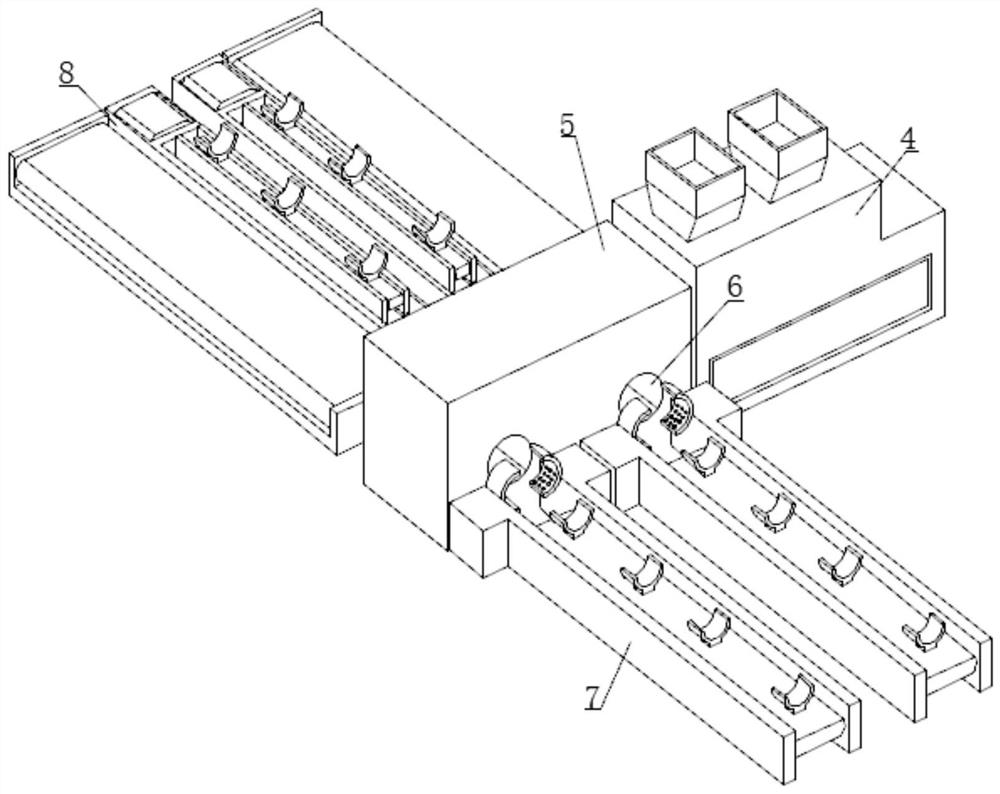

[0051] In order to further better explain the above-mentioned embodiments, the present invention also provides an embodiment, a preparation process of ABS plastics with electromagnetic shielding function, comprising the following steps:

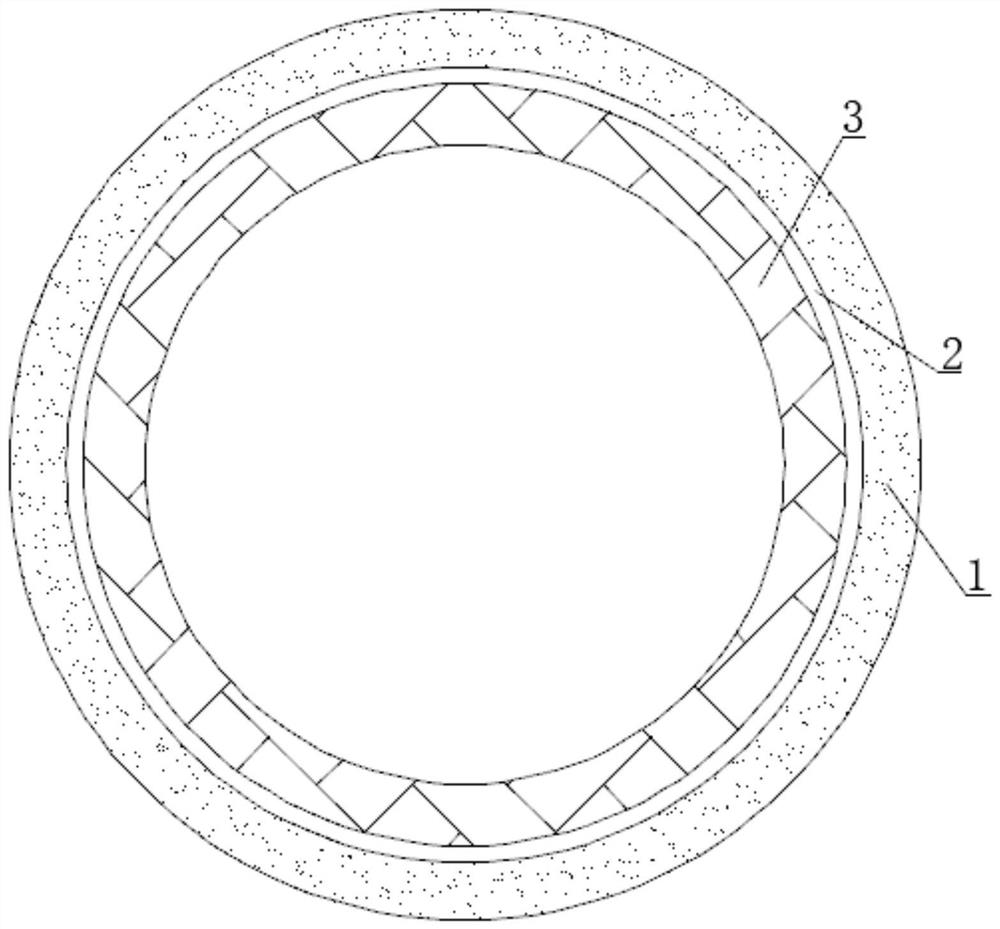

[0052] S1: The inside of the mixing extruder 4 gradually heats up. During the process of heating up the temperature inside the mixing extruder 4, low-density polyethylene, butyl rubber, chlorinated polyethylene, antistatic agent, lubricant, polytetrafluorowax , carbon black and multi-component composite stabilizer are placed into the inside of the mixing extruder 4 according to the heating temperature from low to high to form the electromagnetic shielding layer 1 of the mixed material;

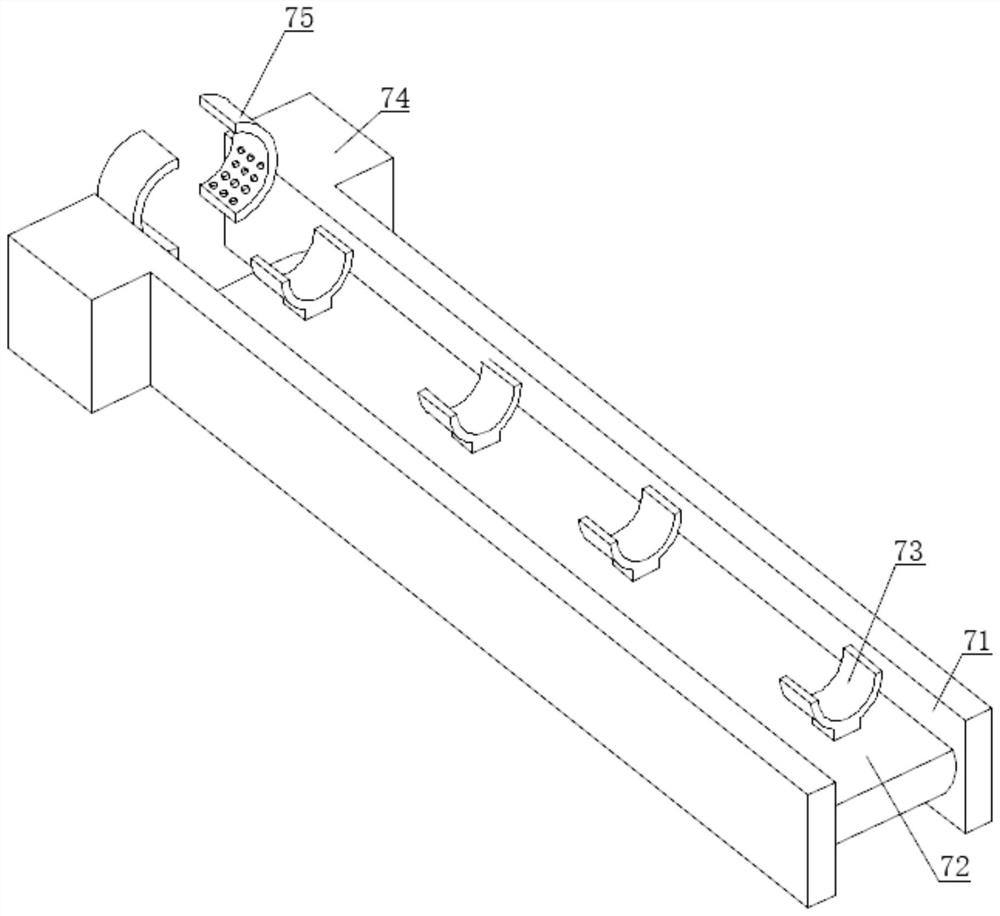

[0053] S2: Apply neoprene adhesive layer 2 on the outside of ABS plastic casing 3 during transportation;

[0054] S3: Apply the electromagnetic shielding layer 1 on the outside of the ABS plastic sleeve 3 and the neoprene adhesive layer 2, and then cool it do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com