Method for removing oxygen-containing compounds in Fischer-Tropsch synthetic oil

A Fischer-Tropsch synthetic oil and compound technology, which is applied in the treatment of hydrocarbon oil, petroleum industry, refined hydrocarbon oil, etc., can solve the problems of low olefin selectivity, short catalyst life, high reaction temperature, etc., and achieve high olefin content, small impact, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

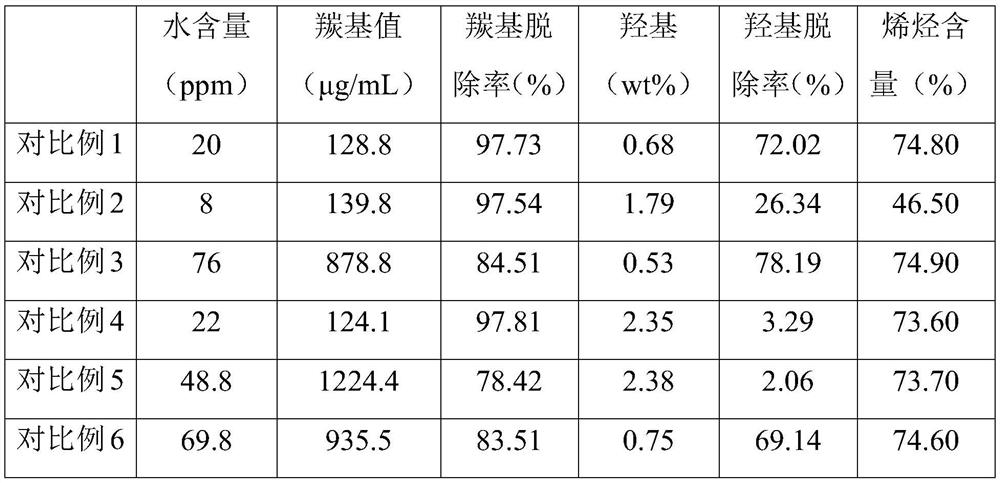

Examples

Embodiment 1

[0066] This embodiment provides a method for removing oxygenated compounds in Fischer-Tropsch synthetic oil (C7 raw oil product), specifically as follows:

[0067] (1) Pre-processing:

[0068] ①Use the air pump to purge the fixed bed reaction device; calibrate the liquid delivery pump.

[0069] ②Catalyst loading:

[0070] Add quartz sand and quartz wool to the lower part of the reactor, then mix sulfonic acid resin (YT-01 sulfonic acid resin) and molecular sieve (3A molecular sieve) in a certain proportion, fill it in the constant temperature zone, and add quartz wool to the upper part.

[0071] ③ Nitrogen purging equipment pipeline.

[0072] (2) Removal process:

[0073] ① Inflate the fixed bed reactor with nitrogen to pressurize the reaction system to 0.5Mpa, and the temperature of the reactor bed rises to 60°C.

[0074] ② Start the pump to transport the Fischer-Tropsch synthetic oil to be processed into the reactor for experimentation.

[0075] ③ Start sampling after t...

Embodiment 2

[0087] This embodiment provides a method for removing oxygenated compounds in Fischer-Tropsch synthetic oil (C7 raw oil product), specifically as follows:

[0088] (1) Pre-processing:

[0089] ①Use the air pump to purge the fixed bed reaction device; calibrate the liquid delivery pump.

[0090] ②Catalyst loading:

[0091] Add quartz sand and quartz wool to the lower part of the reactor, then mix sulfonic acid resin (YT-01 sulfonic acid resin) and molecular sieve (3A molecular sieve) in a certain proportion, fill it in the constant temperature zone, and add quartz wool to the upper part.

[0092] ③ Nitrogen purging equipment pipeline.

[0093] (2) Removal process:

[0094] ① Inflate the fixed bed reactor with nitrogen to pressurize the reaction system to 0.5Mpa, and the temperature of the reactor bed rises to 80°C.

[0095] ② Start the pump to transport the Fischer-Tropsch synthetic oil to be processed into the reactor for experimentation.

[0096] ③ Start sampling after t...

Embodiment 3

[0108] This embodiment provides a method for removing oxygenated compounds in Fischer-Tropsch synthetic oil (C7 raw oil product), specifically as follows:

[0109] (1) Pre-processing:

[0110] ①Use the air pump to purge the fixed bed reaction device; calibrate the liquid delivery pump.

[0111] ②Catalyst loading:

[0112] Add quartz sand and quartz wool to the lower part of the reactor, then mix sulfonic acid resin (YT-01 sulfonic acid resin) and molecular sieve (3A molecular sieve) in a certain proportion, fill it in the constant temperature zone, and add quartz wool to the upper part.

[0113] ③ Nitrogen purging equipment pipeline.

[0114] (2) Removal process:

[0115] ① Inflate the fixed bed reactor with nitrogen to pressurize the reaction system to 0.5Mpa, and the temperature of the reactor bed rises to 100°C.

[0116] ② Start the pump to transport the Fischer-Tropsch synthetic oil to be processed into the reactor for experimentation.

[0117] ③ Start sampling after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com