Amine compound as well as preparation method and application thereof

An amine compound and bonding technology, applied in lubricating compositions, additives, petroleum industry, etc., can solve problems affecting the normal operation of aero-engines, severely corroding equipment, shortening the service life of equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

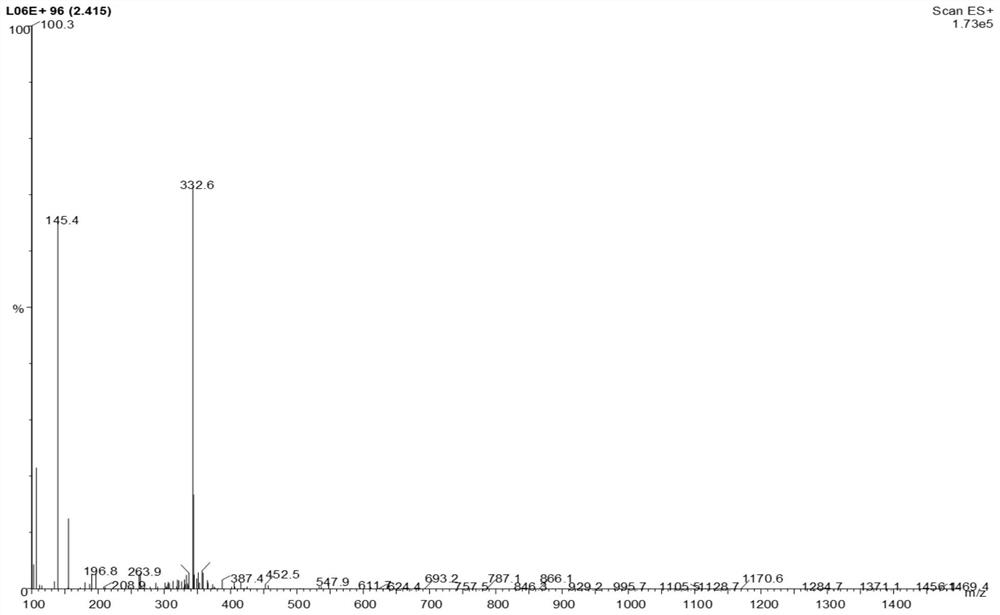

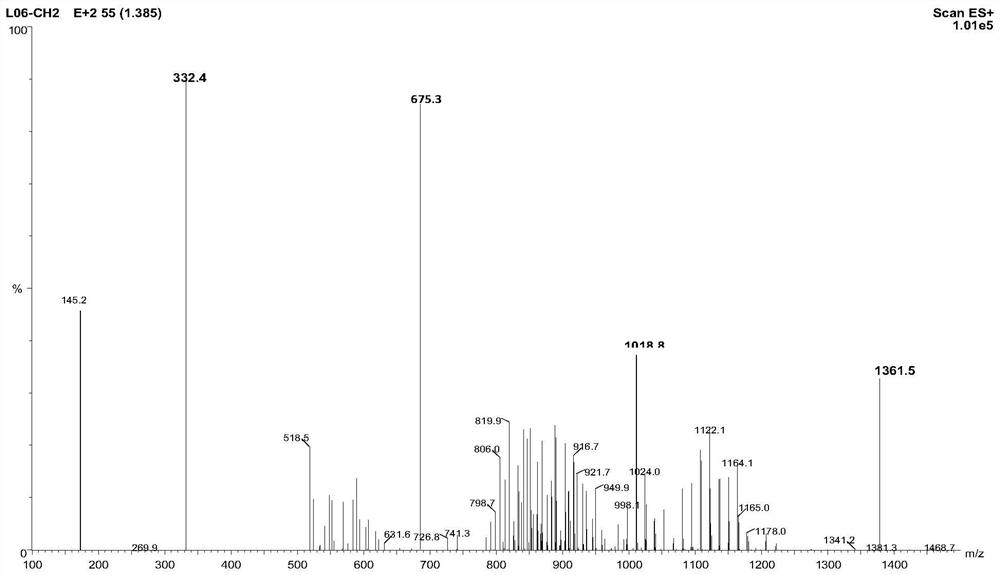

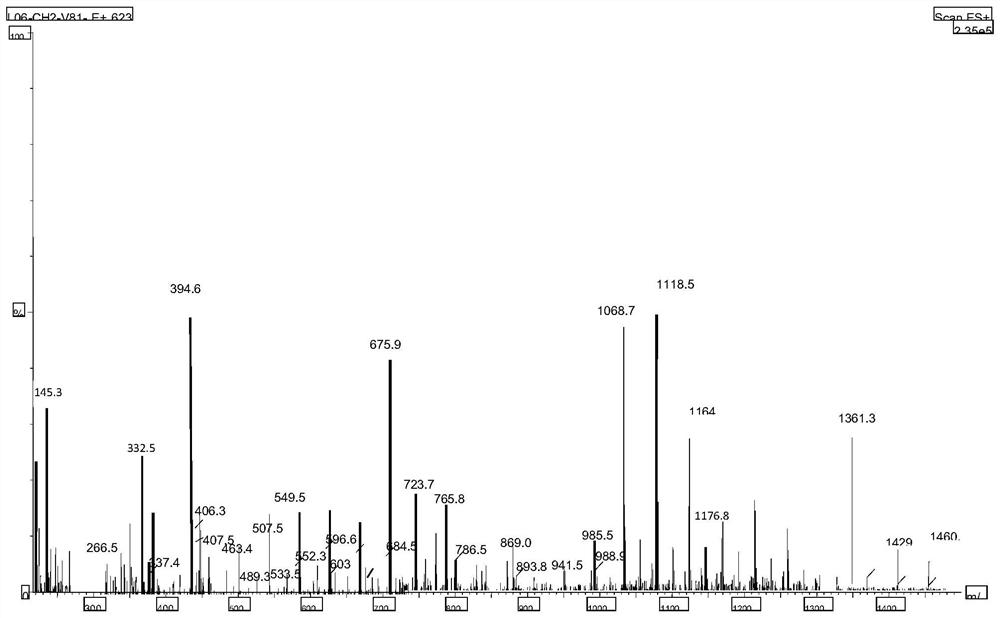

[0107] The N-(p-tert-octylphenyl)-1-naphthylamine of 66.2g is joined in 135 n-decane solvents, sampling pending analysis and characterization, adding 7.2g paraformaldehyde in the mixed system; The reaction system was heated, stirred, and dissolved, and the mixed system was kept within the range of 80°C. Then, 18 g of reaction catalyst glacial acetic acid was added to the reaction system; the reaction was carried out at 120°C for 3 hours, and samples were taken, marked as intermediate product A1 for analysis and characterization, and then the reaction After the system was cooled to 50°C, 78.6 g of 4,4'-diisooctyl-diphenylamine was added to the reaction system, and then the reaction system was heated, and the mixed system was heated, stirred and dissolved in the presence of nitrogen to maintain the mixed system At 145°C, add 125g of di-tert-butyl peroxide to the reaction system, react at a constant temperature of 145°C for 4h, then distill under reduced pressure at 145°C and 0.02...

Embodiment 2

[0124] Add 100 g of N-(p-tert-octylphenyl)-1-naphthylamine to 250 n-decane solvent, add 10 g of paraformaldehyde to the mixed system; heat, stir and dissolve the mixed reaction system under nitrogen atmosphere , keep the mixed system within the range of 80°C, start to add 24g of reaction catalyst glacial acetic acid to the reaction system; carry out the reaction at 100°C for 4h, then cool the reaction system to 50°C in a nitrogen atmosphere, add 4, 108g of 4'-diisooctyl-diphenylamine, then heat the reaction system, heat, stir and dissolve the mixed system in the presence of nitrogen, keep the mixed system at 145°C, add 165g of di-tert-butyl peroxide to the reaction system, React at a constant temperature of 145°C for 4 hours, then distill under reduced pressure at 145°C and 0.02MPa for 60min, then raise the vacuum to ≤0.005MPa, and gradually raise the temperature to and maintain at 175°C for more than 60min under reduced pressure distillation, and complete the vacuum distillati...

Embodiment 3

[0126] Add 120g of N-(p-tert-octylphenyl)-1-naphthylamine into 300g of n-decane solvent, add 15g of paraformaldehyde to the mixed system; heat and stir the mixed reaction system under nitrogen atmosphere to dissolve , keep the mixed system within the range of 90°C, start to add 30g of reaction catalyst glacial acetic acid to the reaction system; carry out the reaction at 125°C for 4h, then cool the reaction system to 50°C in a nitrogen atmosphere, then add 4 , 200g of 4'-diisooctyl-diphenylamine, then heat the reaction system, heat, stir and dissolve the mixed system in the presence of nitrogen, keep the mixed system at 145°C, add 165g of di-tert-butyl peroxide to the reaction system , react at a constant temperature of 145°C for 4h, then distill under reduced pressure at 145°C and 0.02MPa for 60min, then increase the vacuum degree to ≤0.005MPa, and gradually raise the temperature to and maintain at 175°C for more than 80min under reduced pressure distillation, and the vacuum d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com