Amine compound, preparation method and application thereof, and antioxidant composition

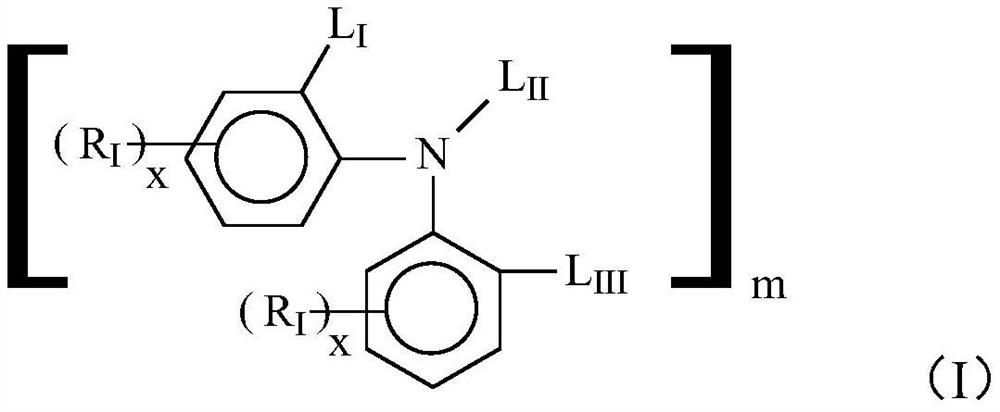

A technology of amine compounds and ester compounds, which is applied in the field of amine compounds with high temperature, anti-oxidation and anti-corrosion properties, can solve the problems of difficult separation and purification, easy precipitation, and unfavorable performance of oil products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

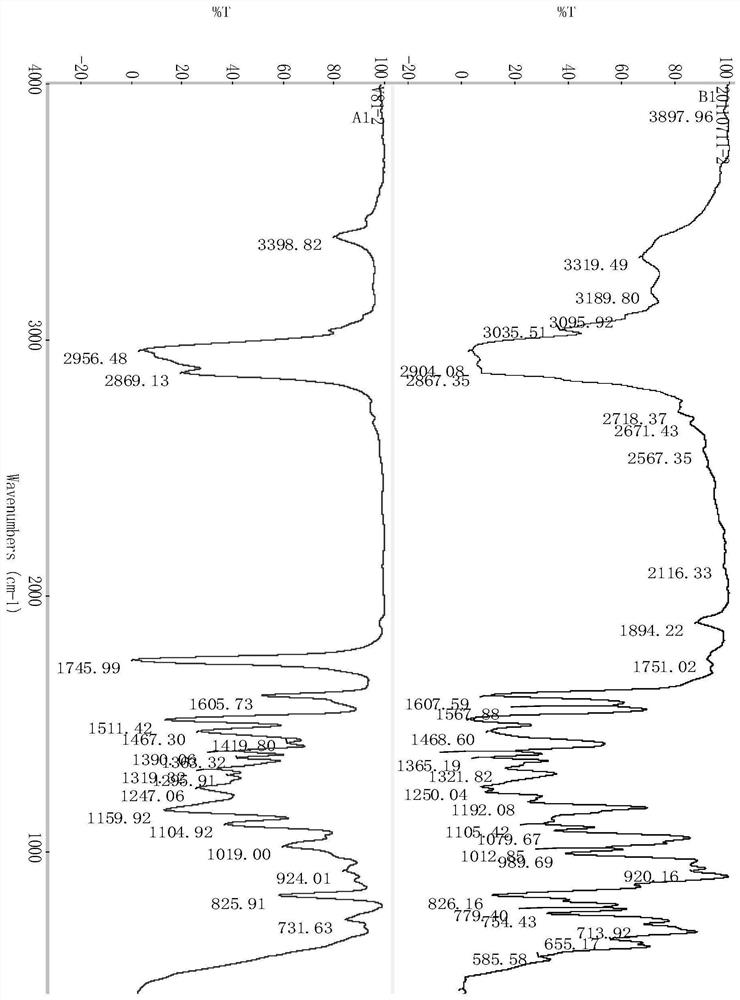

[0160] Add 78g of 4,4'-diisooctyl-diphenylamine to 78g of trimethylolpropane saturated fatty acid ester, and its kinematic viscosity at 100°C=3.8mm 2 / s, the mixed system is heated, stirred and dissolved under a nitrogen environment, and the mixed system is maintained at 145°C, and 56g of initiator di-tert-butyl peroxide is added to the reaction system; the reaction is carried out at 145°C for 4h, and the mixed reaction system is Under reduced pressure distillation at 160°C and vacuum degree <500Pa for 180mins, 152g of reaction product A1 was obtained;

[0161] Add 26g of the reaction raw material 5-methylbenzotriazole to 152g of the reaction product A1, heat and dissolve to form a mixed solution, add 9g of paraformaldehyde condensing agent to the mixed solution, and add 16g of glacial acetic acid to the reaction system at a temperature of 100°C , reacted for 6 hours, carried out sufficient vacuum distillation for 120mins on the mixed reaction system at 110°C and vacuum degree...

Embodiment 2

[0166] Add 155g raw material 4,4'-diisooctyl-diphenylamine to 150g 100°C kinematic viscosity=5.02mm 2 / s mixed polyol saturated ester (wherein the mass ratio of trimethylolpropane ester to dipentaerythritol ester is 3:1), the mixed system is heated, stirred and dissolved under nitrogen atmosphere, and the mixed system is maintained at 140°C. Add 44g of reaction initiator di-tert-butyl peroxide to the reaction system; carry out the reaction at 140°C for 3h, carry out sufficient vacuum distillation on the mixed reaction system at 160°C and vacuum degree <500Pa for 180mins to obtain 310g of reaction product A2 ;

[0167] Put 50g of the reaction raw material 5-methylbenzotriazole into 310g of the reaction product A2, heat and dissolve to form a mixed solution, add 9g of paraformaldehyde condensing agent to the mixed solution, and add 16g of glacial acetic acid to the reaction system at a temperature of 100°C , reacted for 6 hours, carried out sufficient vacuum distillation on the...

Embodiment 3

[0169] Add 80g raw material 4,4'-diisooctyl-diphenylamine to 80g 100℃ kinematic viscosity=7.5mm 2 In the dipentaerythritol ester of / s, heat, stir and dissolve the mixed system under nitrogen atmosphere, maintain the mixed system at 140°C, add 80g of reaction initiator di-tert-butyl peroxide to the reaction system; carry out the reaction at 140°C for 3h, The mixed reaction system was subjected to sufficient vacuum distillation for 180mins at 160°C and vacuum degree <500Pa to obtain 156g of reaction product A3;

[0170] Add 85g of the reaction raw material 5-methylbenzotriazole to 156g of the reaction product A3, heat and dissolve to form a mixed solution, add 9g of paraformaldehyde condensing agent to the mixed solution, and add 32g of glacial acetic acid to the reaction system at a temperature of 100°C , reacted for 6h, and carried out sufficient vacuum distillation for 120mins on the mixed reaction system at 110°C and vacuum degree <500Pa to obtain 26g of transparent bright ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com