Antioxidant composition and preparation method thereof

A composition and antioxidant technology, applied in the directions of lubricating compositions, additives, petroleum industry, etc., can solve the problems of increased lubricating oil viscosity, increased total acid value, strong corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

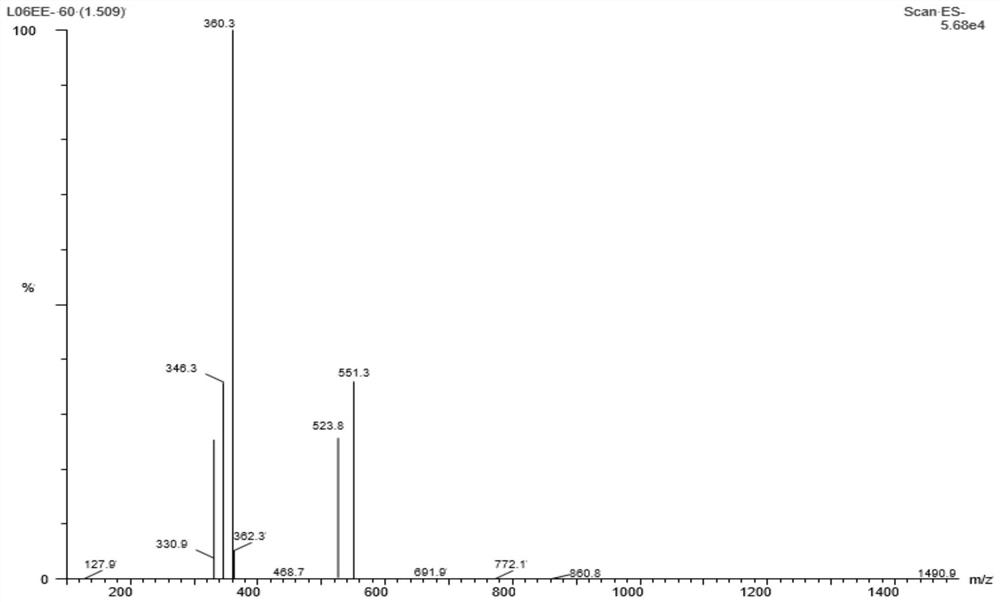

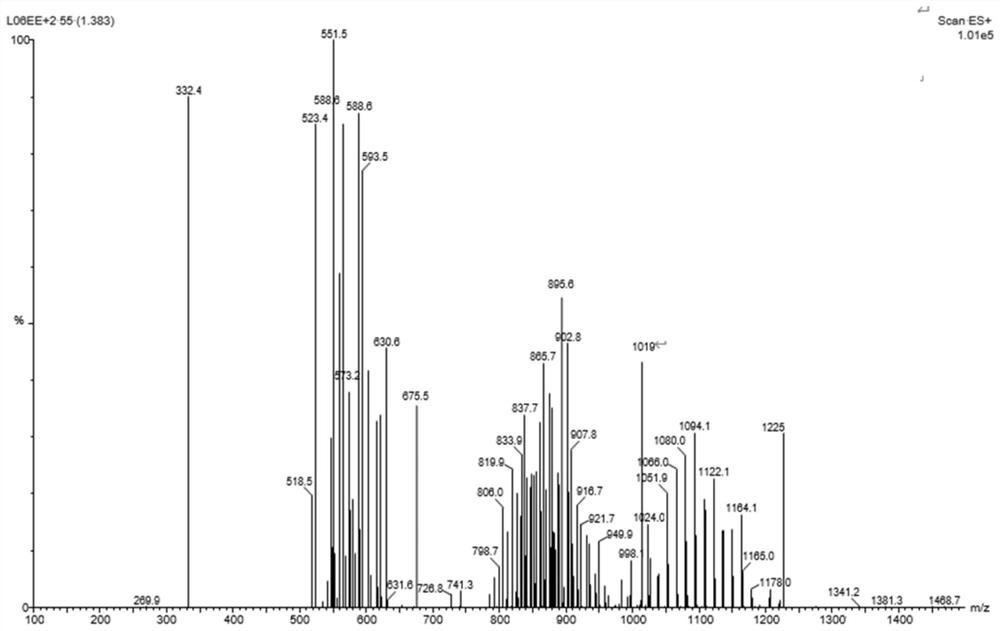

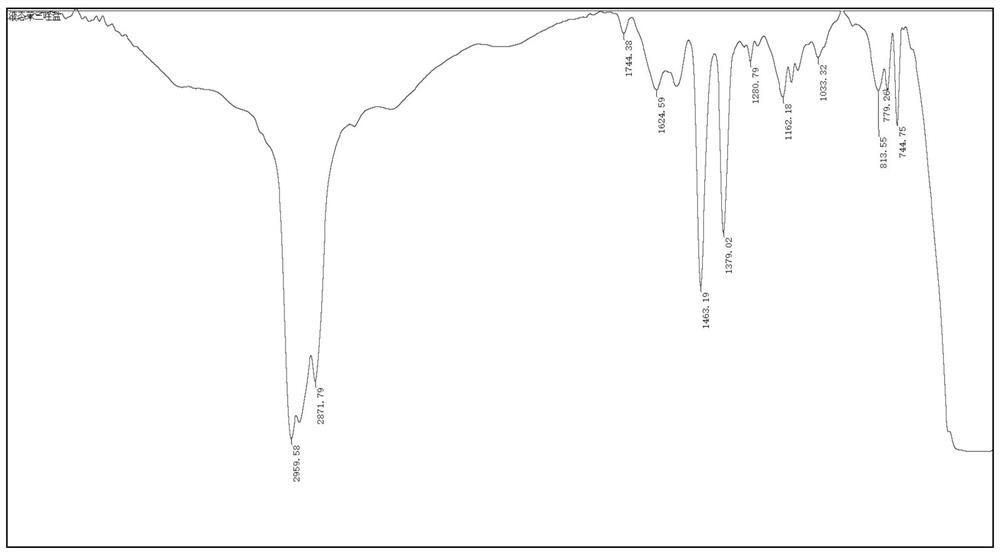

Image

Examples

Embodiment 1

[0116] Add 66.2g of N-(p-tert-octylphenyl)-1-naphthylamine to 72.2g 100°C kinematic viscosity=3.8mm 2 / s of trimethylolpropane saturated fatty acid ester, add 7.2g paraformaldehyde to the mixed system; under nitrogen environment, heat, stir and dissolve the mixed reaction system, keep the mixed system within the range of 80°C, and start to react Add 18g of reaction catalyst glacial acetic acid to the system; carry out the reaction at 100°C for 3h, and conduct vacuum distillation of the mixed reaction system at 110°C and vacuum <500Pa for 60mins, and continue to carry out sufficient decompression at no higher than 160°C and vacuum <500Pa. Distill under reduced pressure for 30mins to 180mins to obtain 142g of reaction product A1; the reaction product A1 mainly contains compounds of structural formula P-1, structural formula P-2, and structural formula P-3, and also contains a small amount of structural formula II'-1 and structural formula II' -2. The compound of structural formu...

Embodiment 2

[0133] Add 99g of N-(p-tert-octylphenyl)-1-naphthylamine into 108g of mixed polyol saturated fatty acid esters (81g of trimethylolpropane esters, 27g of dipentaerythritol esters), and add to the mixing system Add 12g of paraformaldehyde; heat, stir and dissolve the mixed reaction system under nitrogen atmosphere, keep the mixed system at about 90°C, start adding 22g of reaction catalyst glacial acetic acid to the reaction system; At 110°C, vacuum <500Pa vacuum distillation for 60mins, continue to carry out sufficient vacuum distillation at no higher than 160°C, vacuum <500Pa for 30mins to 180mins, to obtain 210g of reaction product A2; reaction product A2 mainly contains Structural formula P-1, structural formula P-2, the compound of structural formula P-3 similar structure (the difference is that the ester group wherein is the ester group of the mixed polyhydric alcohol saturated fatty acid ester used in this embodiment), contains relatively A small amount of compounds of str...

Embodiment 3

[0137] The N-(p-tert-octylphenyl)-1-naphthylamine of 132g is added to 156g four centistein polyol saturated fatty acid esters (wherein trimethylolpropane ester 78g, pentaerythritol ester 78g, both mass ratios are 1:1), add 30g of paraformaldehyde to the mixed system; heat, stir and dissolve the mixed reaction system under nitrogen environment, keep the mixed system at about 100°C, and start adding 30g of reaction catalyst glacial acetic acid to the reaction system; Carry out 3h at 100°C, carry out vacuum distillation of the mixed reaction system at 110°C, vacuum <500Pa for 60mins, continue to carry out sufficient vacuum distillation at no higher than 160°C, vacuum <500Pa for 30mins to 180mins, and obtain 153.5g Reaction product A3; Reaction product A3 mainly comprises the compound (difference is that the ester group wherein is the polyhydric alcohol saturated fatty acid ester used in this example) with structural formula P-1, structural formula P-2, structural formula P-3 simil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com