Washing barrel assembly and pulsator washing machine

A technology of washing tubs and components, which is applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of reduced processing capacity of ordinary clothes, waste of money and power resources, and occupation of main washing space, so as to save home space and avoid Waste and the effect of preventing cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

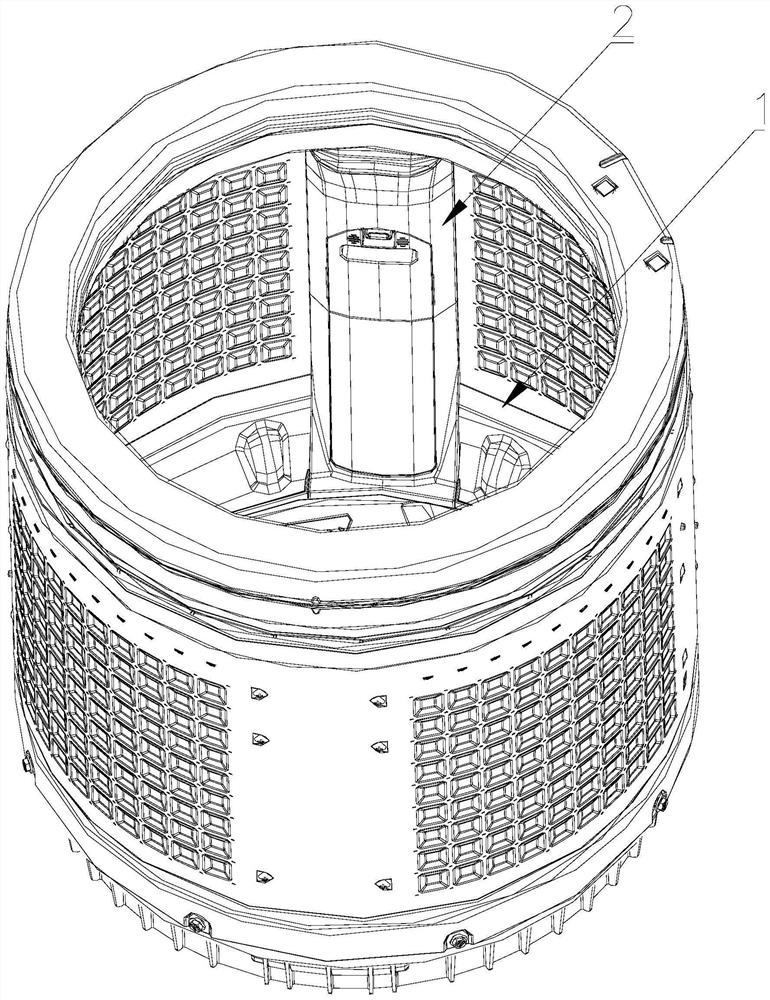

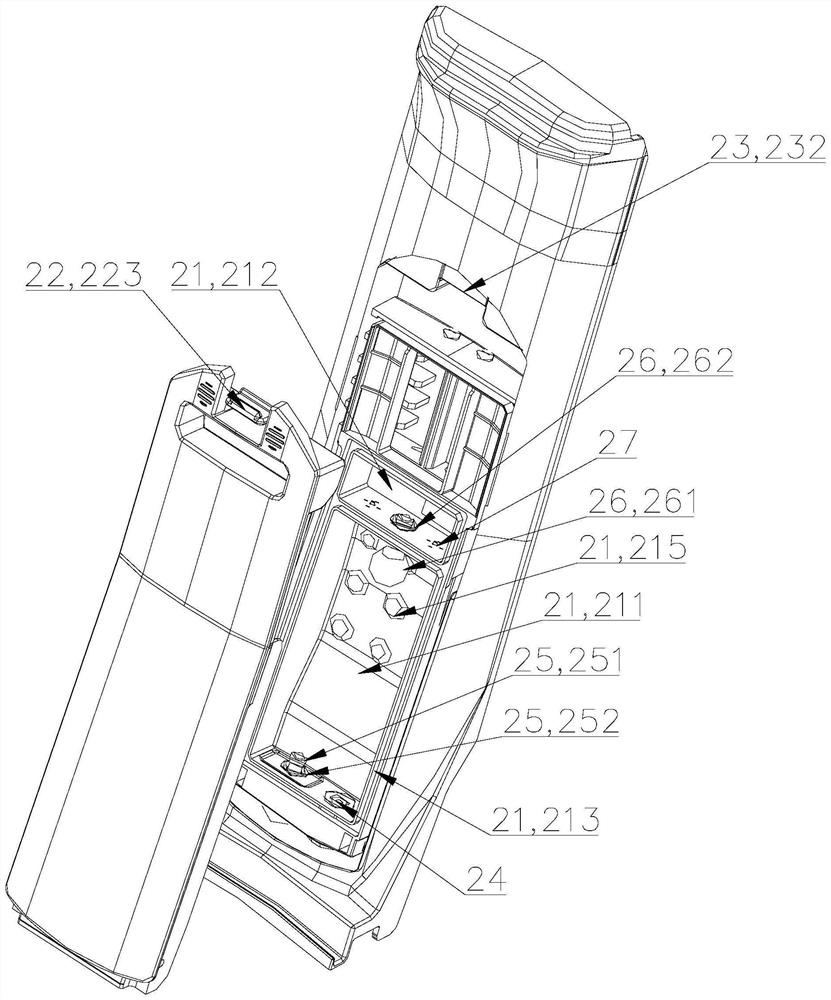

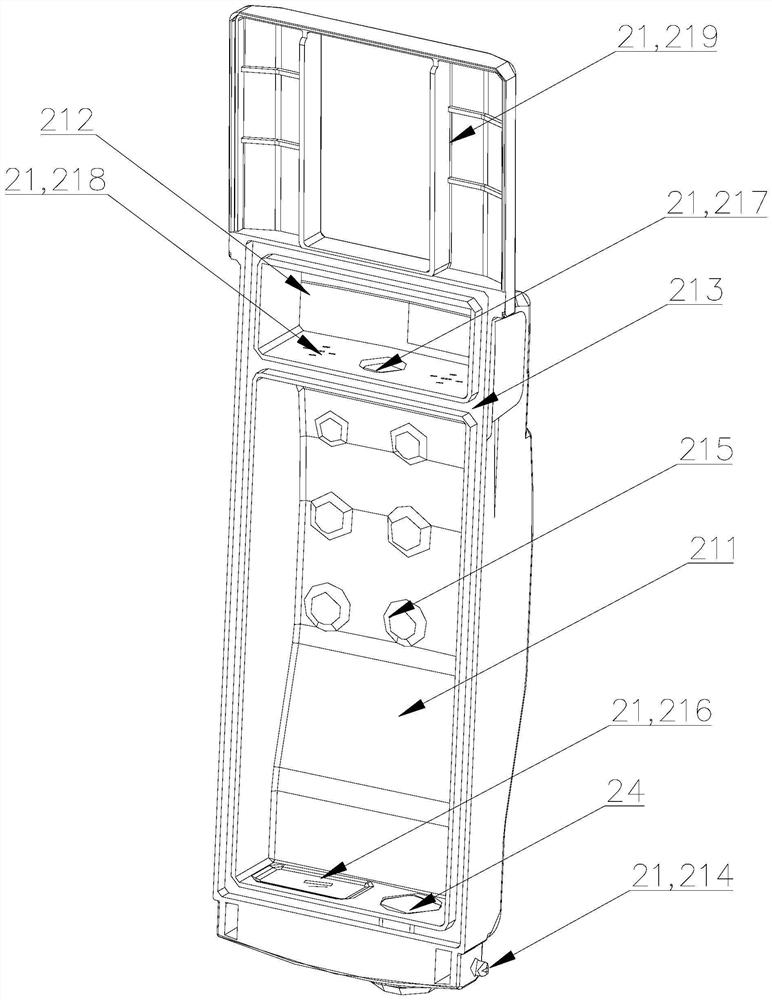

[0040] Such as figure 1 As shown, a washing tub 1 assembly is provided in this embodiment, including a washing tub 1 with a main washing chamber, an auxiliary washing unit 2 is installed on the washing tub 1, and the auxiliary washing unit 2 has an auxiliary washing chamber 211, and the auxiliary washing chamber 211 is provided. The washing chamber 211 communicates with the main washing chamber. The auxiliary washing unit 2 is installed on the washing tub 1, and is used for independently washing small pieces of clothing such as underwear and socks that need to be cleaned separately, and does not occupy the main washing space of the washing tub 1. At the same time, the auxiliary washing unit 2 has a The connected auxiliary washing chamber 211 shares the power system, water inlet system, drainage system, etc. with the washing tub 1, which is convenient for industrial production.

[0041] Such as figure 1 and figure 2 As shown, in this embodiment, the auxiliary washing unit 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com