Supercritical carbon dioxide and steam coupling cycle power generation system and method for photo-thermal afterburning

A technology of cycle power generation and carbon dioxide, applied in steam engine devices, machines/engines, mechanical equipment, etc., to achieve stable power generation, cost saving, and high cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

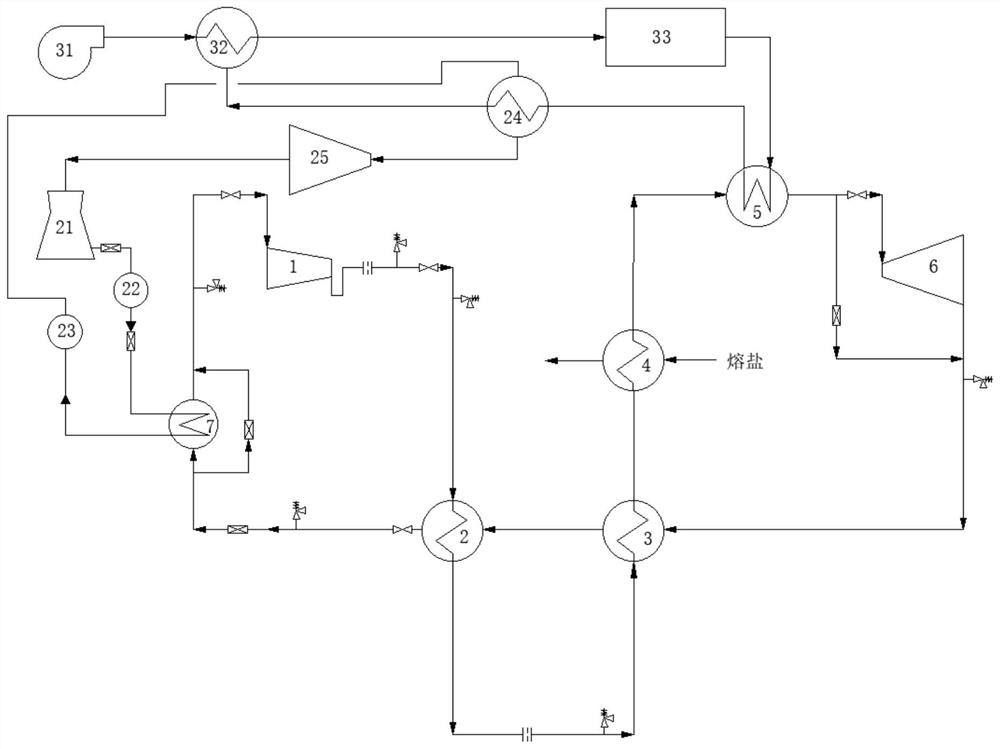

[0070] This embodiment provides a supercritical carbon dioxide and steam coupled cycle power generation system and method for photothermal supplementary combustion. The coupled cycle power generation system includes s-CO 2 Cycle power generation system, steam cycle power generation system and supplementary combustion system;

[0071] The s-CO 2 The main circuit of the cycle power generation system includes a main compressor 1, a low temperature regenerator 2, a high temperature regenerator 3, a preheater 4 (molten salt heater), a main heat exchanger 5 and a first turbine 6 connected in sequence, The first turbine 6 is connected to the first cooler 7 through the high temperature regenerator 3 and the low temperature regenerator 2 in sequence, and the first cooler 7 is connected to the main compressor 1 again, form a loop;

[0072] The s-CO 2 The main circuit of the cycle power generation system also includes a first branch pipeline and a second branch pipeline;

[0073] The...

Embodiment 2

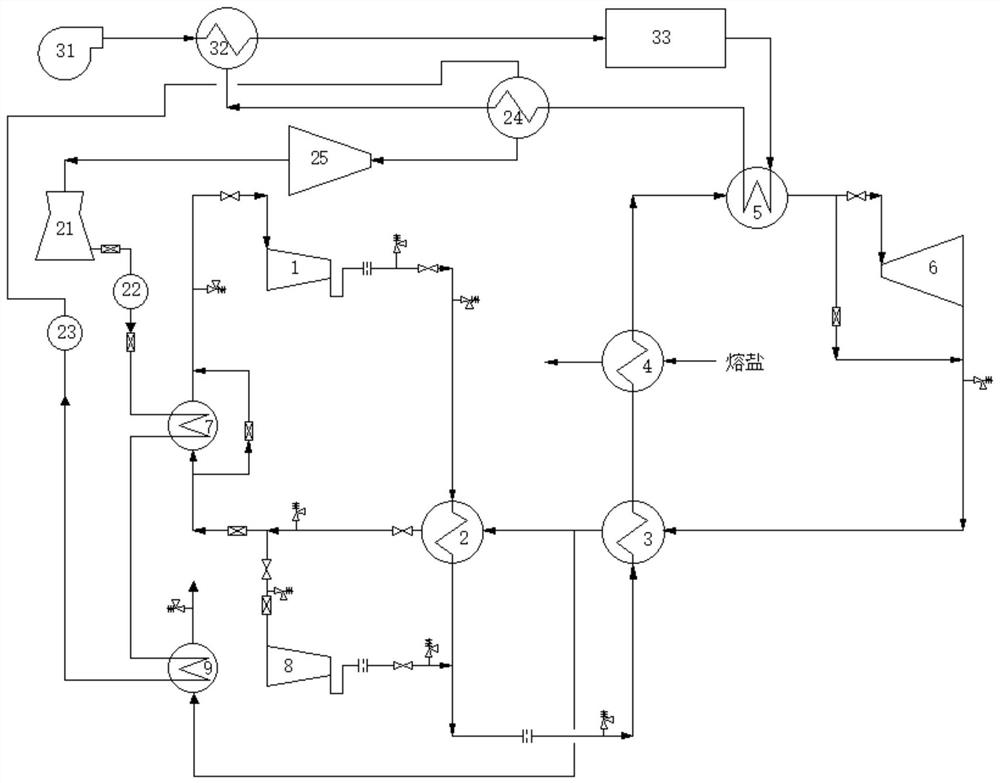

[0082] This embodiment provides a supercritical carbon dioxide and steam coupled cycle power generation system and method for photothermal supplementary combustion. The coupled cycle power generation system includes s-CO 2 Cycle power generation system, steam cycle power generation system and supplementary combustion system;

[0083] The s-CO 2 The main circuit of the cycle power generation system includes a main compressor 1, a low temperature regenerator 2, a high temperature regenerator 3, a preheater 4 (molten salt heater), a main heat exchanger 5 and a first turbine 6 connected in sequence, The first turbine 6 is connected to the first cooler 7 through the high temperature regenerator 3 and the low temperature regenerator 2 in sequence, and the first cooler 7 is connected to the main compressor 1 again, form a loop;

[0084] The s-CO 2 The main circuit of the cycle power generation system also includes a first branch pipeline and a second branch pipeline;

[0085] The...

Embodiment 3

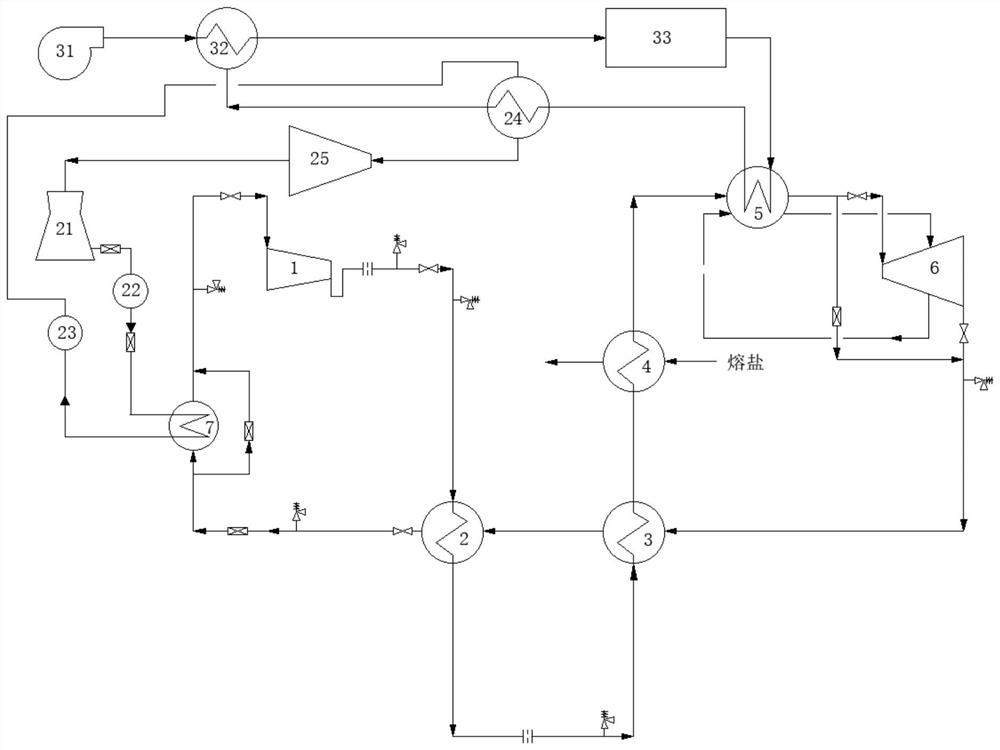

[0097] This embodiment provides a supercritical carbon dioxide and steam coupled cycle power generation system and method for photothermal supplementary combustion. The coupled cycle power generation system includes s-CO 2 Cycle power generation system, steam cycle power generation system and supplementary combustion system;

[0098] The s-CO 2 The main circuit of the cycle power generation system includes a main compressor 1, a low temperature regenerator 2, a high temperature regenerator 3, a preheater 4 (molten salt heater), a main heat exchanger 5 and a first turbine 6 connected in sequence, The first turbine 6 is connected to the first cooler 7 through the high temperature regenerator 3 and the low temperature regenerator 2 in sequence, and the first cooler 7 is connected to the main compressor 1 again, form a loop;

[0099] The s-CO 2 The main circuit of the cycle power generation system also includes a first branch pipeline and a second branch pipeline;

[0100] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com