Open type turnover oil tank and working method thereof

A working method and fuel tank technology, applied in fuel supply tank devices, valve operation/release devices, instruments, etc., can solve problems such as oil leakage, unusable open fuel tanks, etc., to achieve strong heat dissipation, easy maintenance and cleaning, pressure small change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

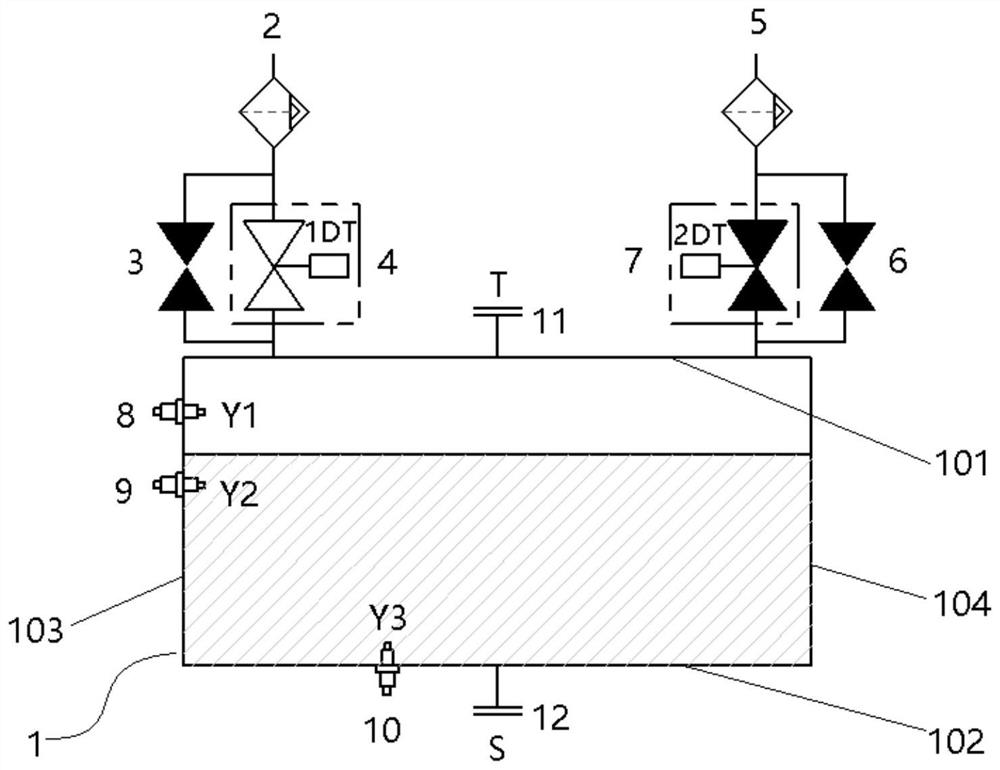

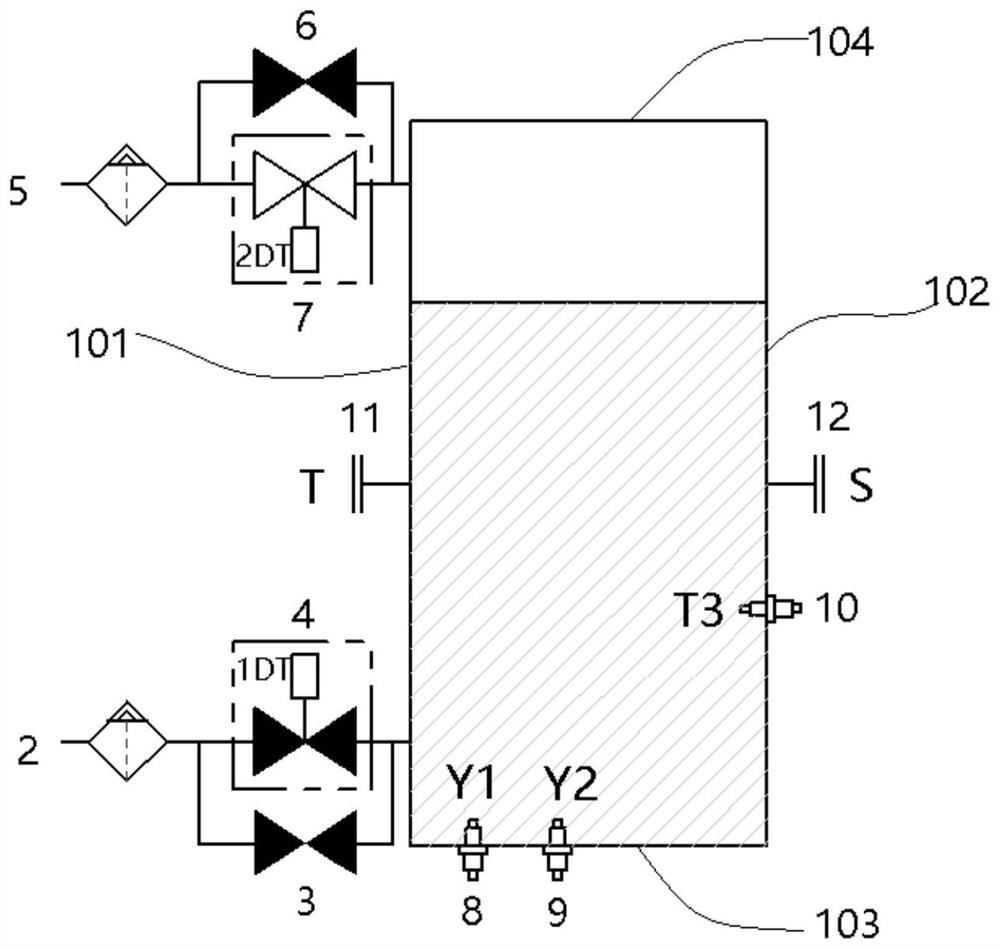

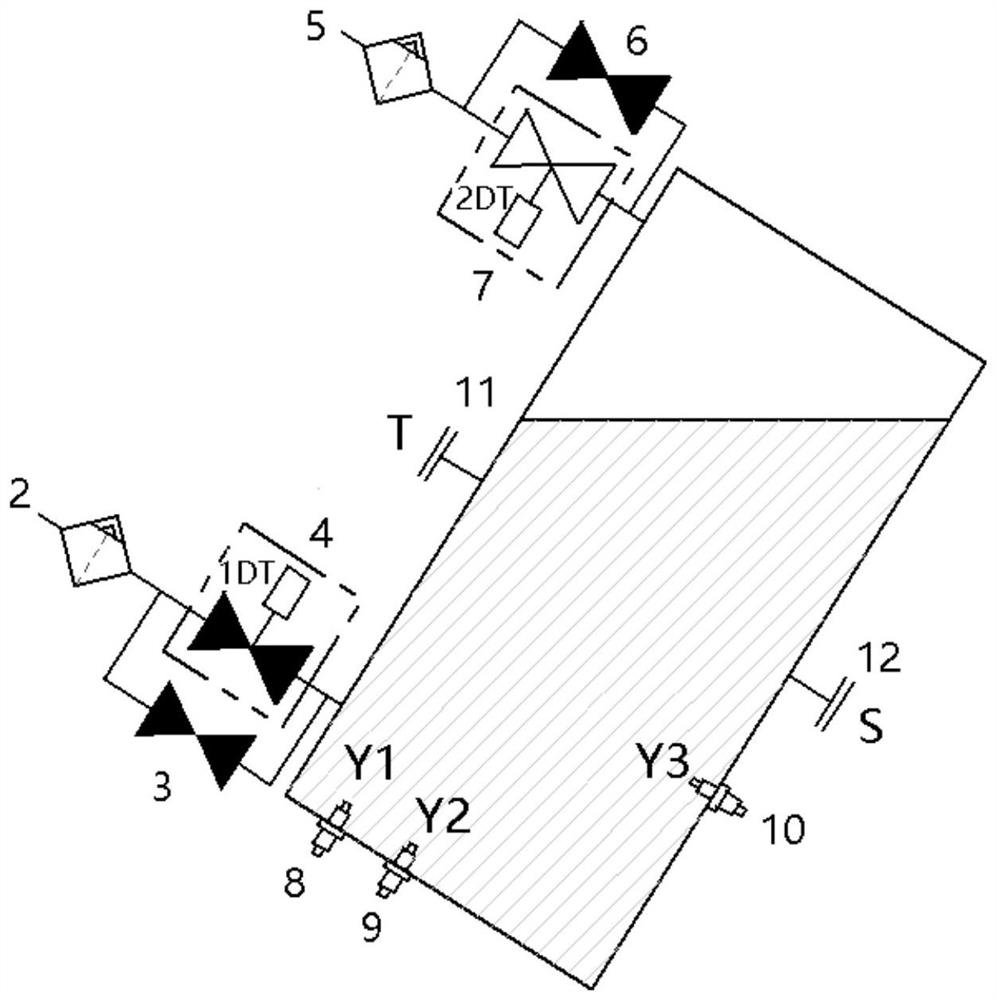

[0045] figure 1 It is a schematic diagram of the attitude of an open flip fuel tank before the work starts.

[0046] Such as figure 1 As shown, an open-type reversible fuel tank includes: a tank body 1, and the tank body 1 includes a top plate 101, a bottom plate 102 and side plates. An oil suction port 12 is provided on the bottom plate 102 , and the oil suction port 12 communicates with the box body 1 . An oil return port 11 is provided on the top plate 101 , and the oil return port 11 communicates with the box body 1 . A first air filter 2 and a second air filter 5 are also provided on the top plate 101 , and the first air filter 2 and the second air filter 5 are arranged on both sides of the oil return port 11 . The oil return port 11 is preferably disposed at the center of the top plate 101 , and the first air filter 2 and the second air filter 5 are symmetrically disposed on both sides of the oil return port 11 . Wherein, the first air filter 2 communicates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com