Multi-phase cooling method and device for bearing surface laser quenching

A technology of laser quenching and cooling method, which is applied in the direction of quenching device, furnace type, furnace, etc., can solve the problems of self-tempering, decrease of steam film cooling capacity, deformation accuracy, etc., to reduce the impact of hardness, reduce impact, and reduce deformation volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The metal block is made of copper, the coolant is water, and the inert gas is nitrogen.

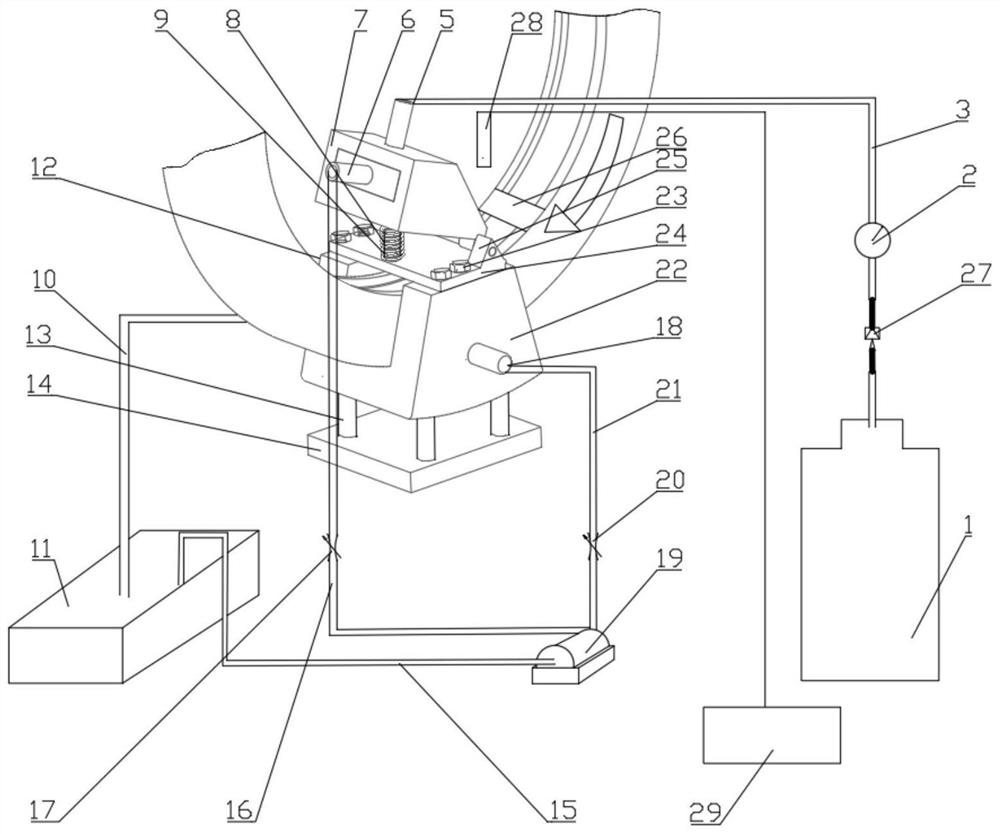

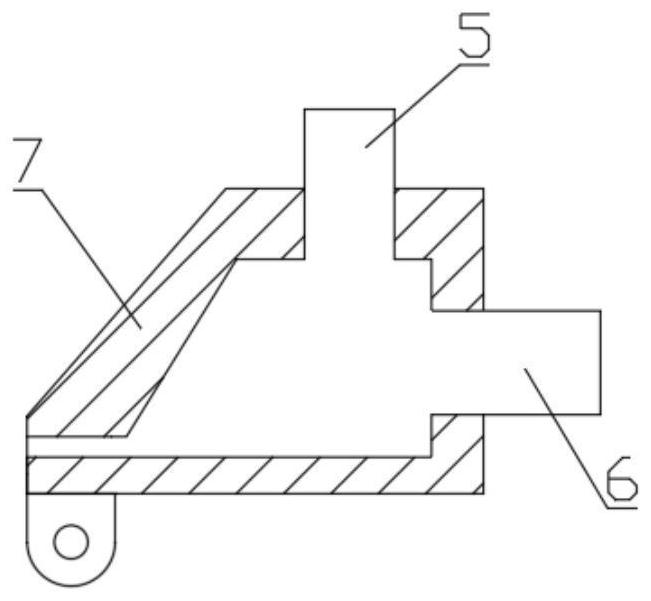

[0022] Such as figure 1 As shown, a cooling device for laser quenching of the bearing surface can be used for laser quenching cooling of the inner raceway of the bearing, including a bearing 4 , a nozzle 7 , and a heat-conducting copper block 22 . Wherein the heat-conducting copper block 22 is fixed on the workbench 14 through the pillar 13, and the height of the workbench is adjusted so as to keep the contact between the copper block and the bearing; The valve 20, the main water inlet pipe 15, and the copper block water outlet pipe 10 are connected to form a circulating waterway, so that the heat-conducting copper block can be continuously cooled; the laser is fixed, the laser spot irradiation position 26 is fixed, and the bearing is driven to rotate by the turntable , forming a relative rotational movement with the heating spot; the spray head 7 is fixed on the sup...

Embodiment 2

[0024] Embodiment 2: The metal block is made of copper, the coolant is water, and the inert gas is nitrogen.

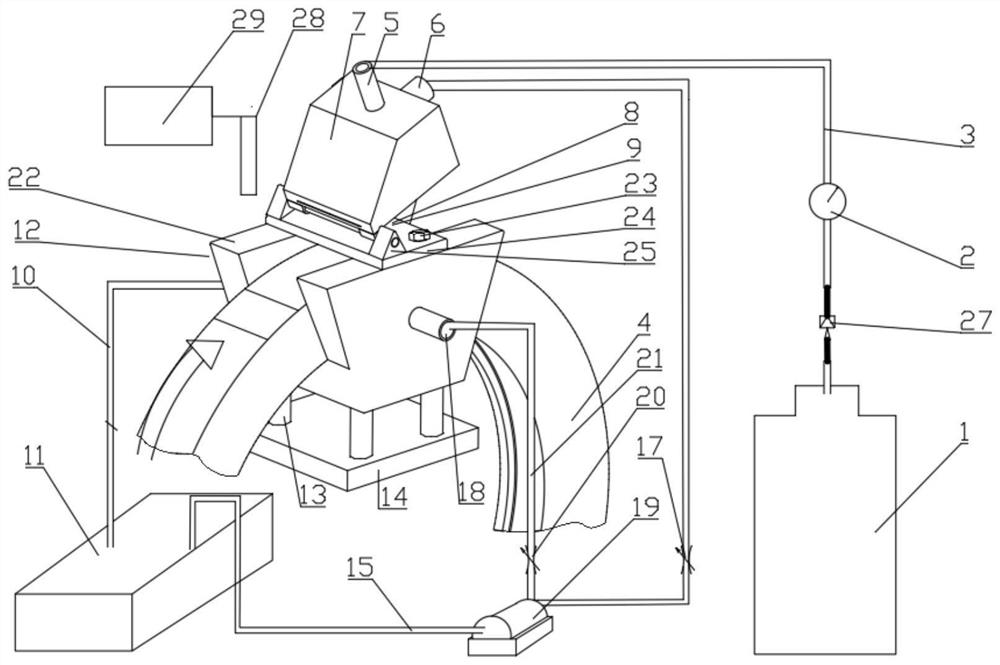

[0025] A cooling device for laser quenching of the bearing surface, such as figure 2As shown, it can be used for laser quenching and cooling of bearing outer raceway. Its structure and embodiment are substantially the same as those in Example 1, but the installation positions of the spray head 7 and the like are different. The laser irradiation position 26 is located on the outer raceway of the bearing. The water mist and nitrogen gas sprayed from the nozzle 7 cool the quenching area. At the same time, the heat-conducting copper block that is in contact with the bearing on three sides can increase the speed of the bearing’s heat transfer to the outside, thereby reducing the heating area. The closed-loop control composed of the controller 29, the temperature sensor 28 and the pump 19 can ensure the stability of the cooling process, thereby ensuring the uniformity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com