Laser infrared multiband compatible stealth film made of non-metallic material and preparation method thereof

A non-metallic material and multi-band technology, applied in the field of laser infrared multi-band compatible stealth film and its preparation, can solve the problems of weak radiation, affecting the heat dissipation of the target, affecting the normal operation of the target, etc., achieving thin thickness, improving survival probability, and easy The effect of large-scale production and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiment:

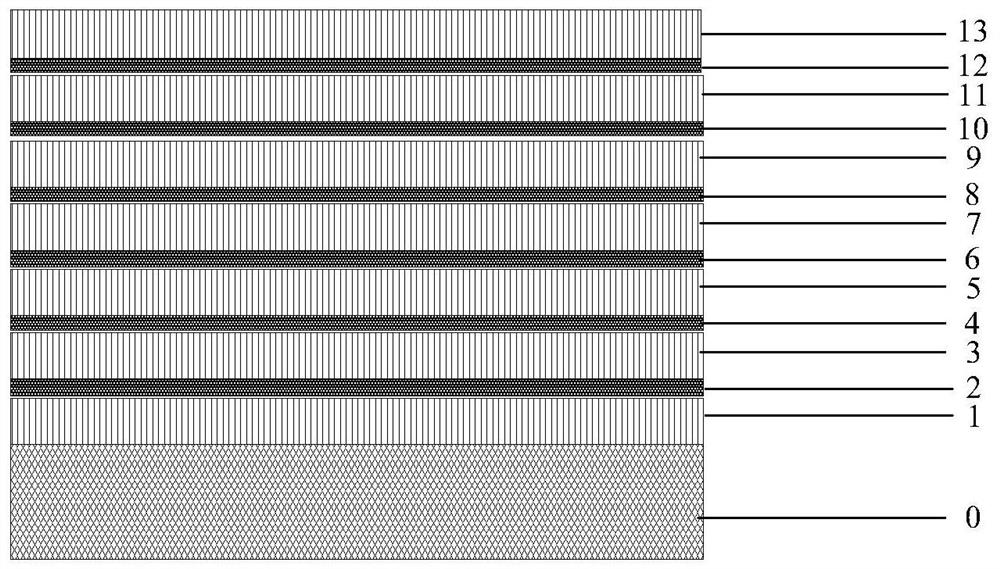

[0020] refer to figure 1 The laser infrared multi-band compatible stealth film of non-metallic materials shown is a multi-layer film structure, the substrate is made of PI film, and calcium fluoride (CaF2) material film layers and tellurium (Te) material films are alternately stacked on the substrate layer (13 layers in total), the 1st and 13th layers are calcium fluoride layers, the thickness of each film layer from inside to outside is as follows: 910nm, 704nm, 211nm, 293nm, 63nm, 1032nm, 574nm, 50nm, 1326nm, 153nm, 429nm, 118nm, 983nm.

[0021] This embodiment is prepared by electron beam evaporation coating method, and the process parameters of preparation: the background vacuum degree is 5.0×10 - 3 Pa, the deposition rate of tellurium (Te) is 0.9nm / s, the deposition rate of calcium fluoride (CaF2) is 0.8nm / s, and the substrate temperature is 120°C.

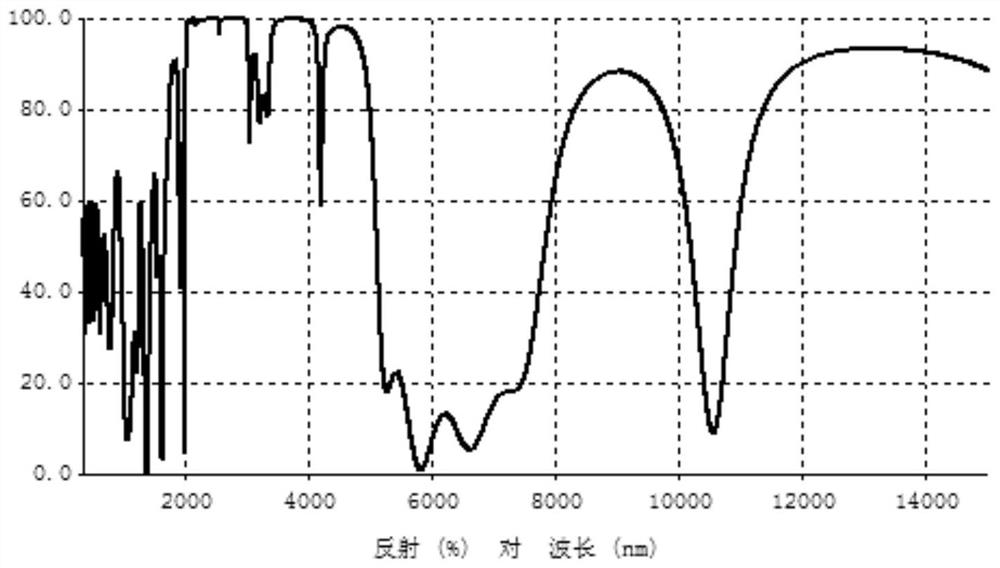

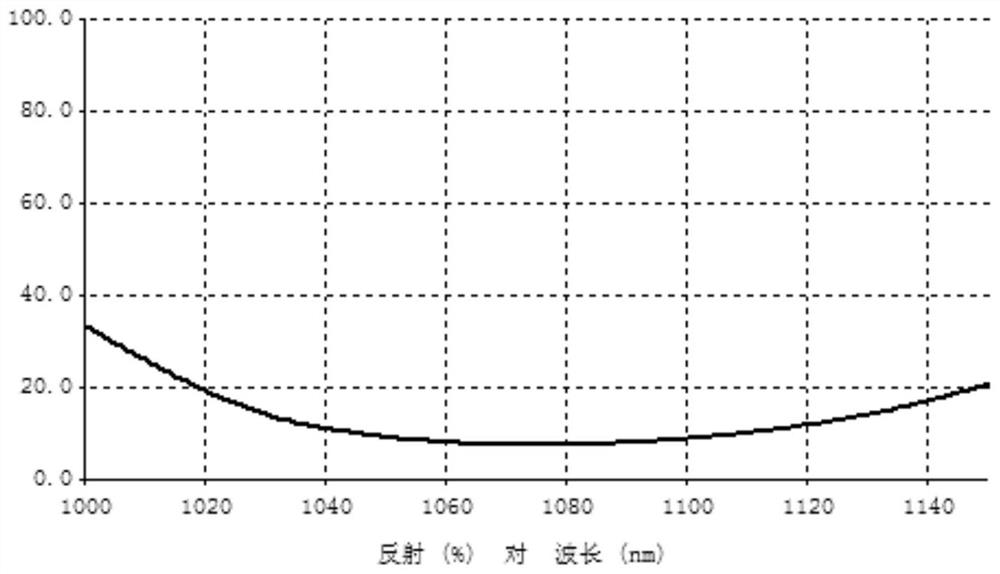

[0022] figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com