Device for testing wall adhesion temperature of high-water-content gas-dissolved crude oil

A testing device, water-soluble gas technology, applied in the investigation phase/state change and other directions, can solve problems such as the sticky wall law of crude oil that has not been involved in high water-soluble gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to understand the content of the invention more clearly, it will be described in detail with reference to the drawings and embodiments.

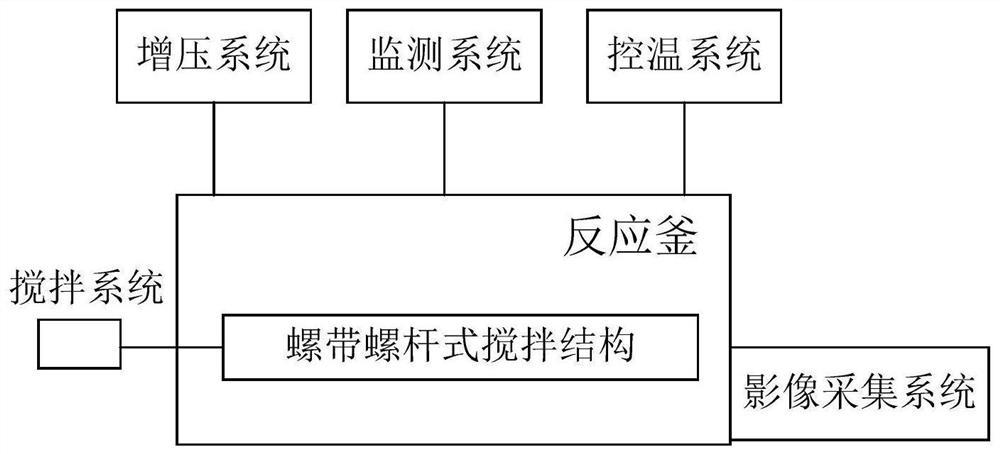

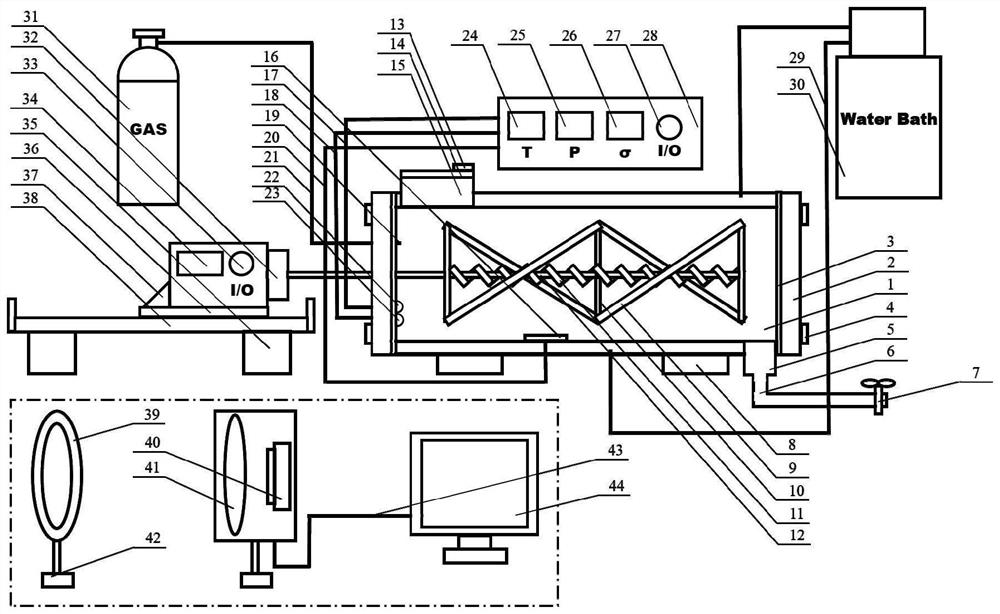

[0029] The invention relates to a device for testing the wall sticking temperature of crude oil with high water-soluble gas content, such as figure 1 The structural block diagram shown includes a reactor, a stirring system, a monitoring system, a temperature control system, a pressurization system, and an image acquisition system. To simulate the actual pipeline, the temperature control system and the pressurization system simulate the pipeline operation conditions by controlling the temperature and pressurization of the reactor respectively. The stirring system has a screw-ribbon stirring structure. Stirring in the tank is used to simulate the scouring and shearing process of the pipe flow. The monitoring system collects and monitors the pressure, temperature and oil condensation stress in the reactor. Image acquisition is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com