System and method for measuring composite thermal parameters of phase change concrete member

A composite thermal and concrete technology, applied in the direction of material thermal development, can solve the problems of large error in measurement results and the limitations of thermal parameters that cannot be well characterized, and achieve the effect of avoiding errors, reducing experimental measurement errors, and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

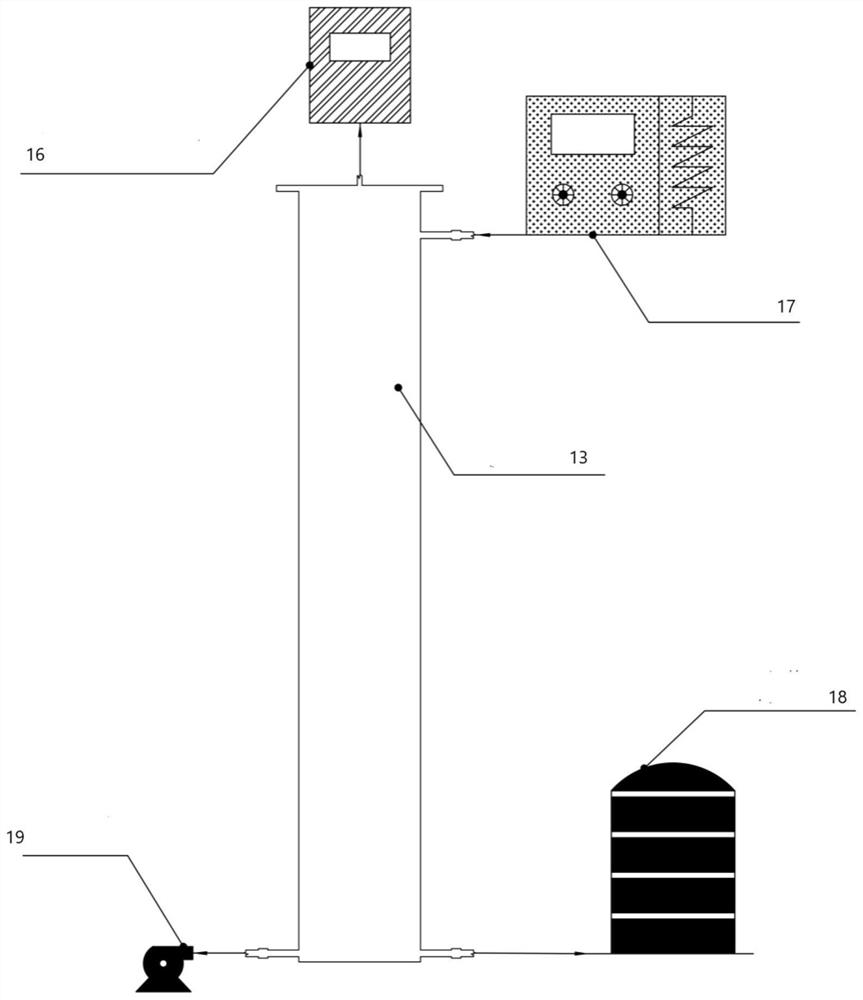

[0071] The embodiment of the present invention discloses a system for measuring composite thermal parameters of phase change concrete components, including: a model unit, a loading unit, an air handling unit, and a monitoring unit, such as figure 1 As shown, the model unit includes a metal container 13. The metal container 13 is a container matching any common size and shape of the component to be tested, and is used to hold the component to be tested 5, and to measure the composite thermal parameters of the component to be tested 5 with different sizes and shapes. The model units are respectively It is connected with the loading unit and the air handling unit, and the component 5 to be tested is a phase change concrete material;

[0072] The air processing unit includes: an air outlet 9 and a vacuum pump 19; the air outlet 9 is arranged on the metal container and connected to the vacuum pump 19 through a pipeline;

[0073] The loading unit provides different constant temperat...

Embodiment 2

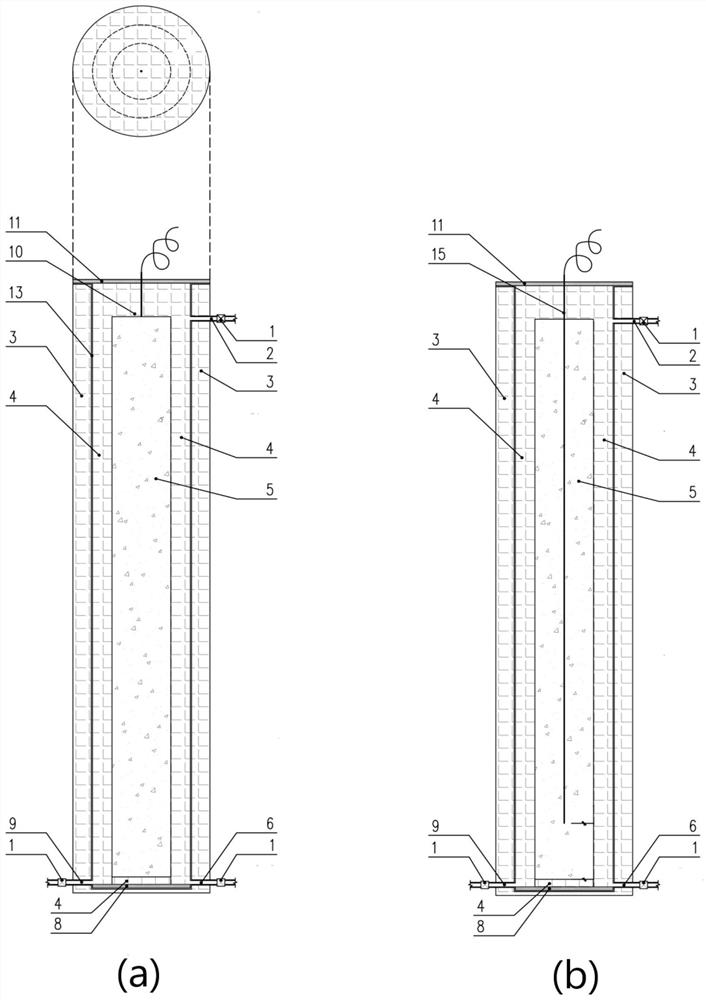

[0076] The embodiment of the invention discloses a system for measuring the composite thermal parameters of phase change concrete components, using the transient method to measure the thermal conductivity, such as figure 2 As shown, the model unit includes: barrel outer insulation material 3, barrel inner insulation material 4, component to be tested 5, barrel bottom insulation material 8, barrel top insulation material 11, metal container 13, and the loading unit includes: constant temperature heating The device 16, the line heat source 15, and the monitoring unit include: a temperature sensor 22, a heat flux sensor 21, and the sensor is connected to a computer through a collector.

[0077] In this embodiment, first place the component to be tested 5 and the insulating and heat insulating material in a metal container 13, insert the line heat source 15 into the reserved hole of the component to be tested 5, fill the gaps with high thermal conductivity silica gel, and then pas...

Embodiment 3

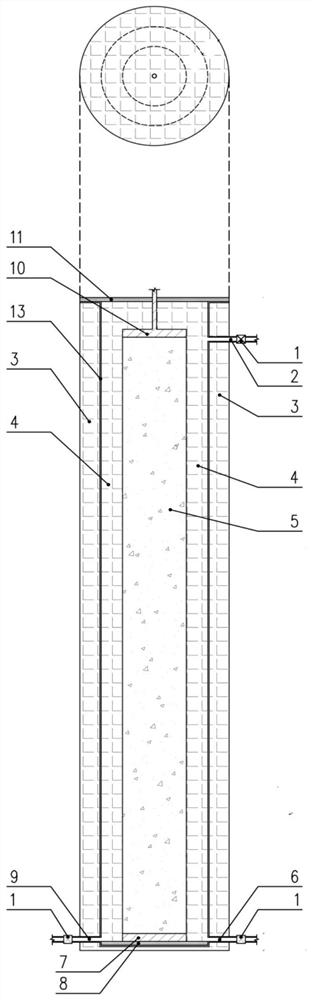

[0101] The embodiment of the present invention discloses a system for measuring the composite thermal parameters of phase change concrete components, using the steady-state method to measure the thermal conductivity and thermal expansion coefficient, such as image 3 As shown, the model unit includes: barrel outer insulation material 3, barrel inner insulation material 4, component to be tested 5, barrel bottom insulation material 8, barrel top insulation material 11, metal container 13, and the loading unit includes: constant temperature heating Device 16, constant temperature cold plate 7, constant temperature heating plate 10, water circulation temperature control device 17, the monitoring unit includes: temperature sensor 22, heat flux sensor 21, strain gauge 23, the sensor is connected to the computer through the acquisition instrument.

[0102] In this embodiment, the heat flux sensors 21 are first attached to the upper and lower surfaces of the component to be measured 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com