Power plant mother pipe coordination control and polling recursive distribution method

A technology of coordinated control and distribution method, applied in the direction of control system, adaptive control, general control system, etc., can solve the problems of boiler following control and automatic control of main pressure, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0135] Suppose a power plant is equipped with 4 boilers and 4 units, the unit capacity is 4×125MW units, and the operating parameters during normal production are

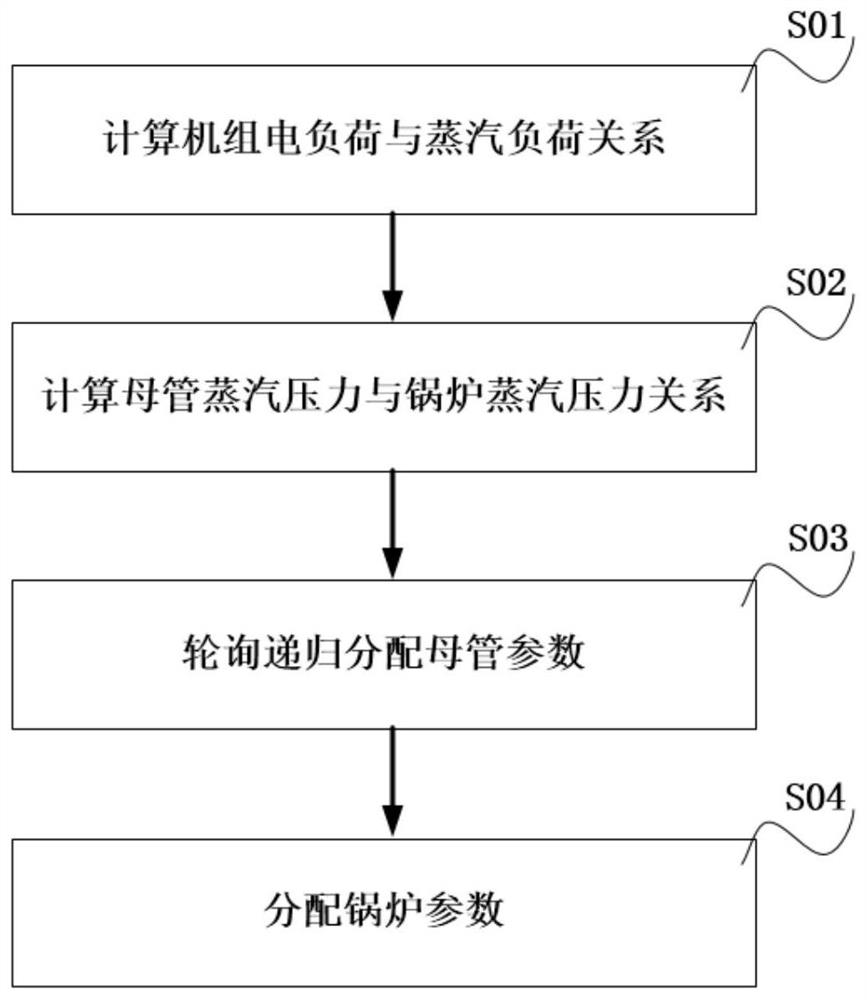

[0136] According to the method proposed by the present invention, carry out the calculation of following four processes respectively:

[0137] Step S01: the relationship between the electrical load of the computer set and the steam load;

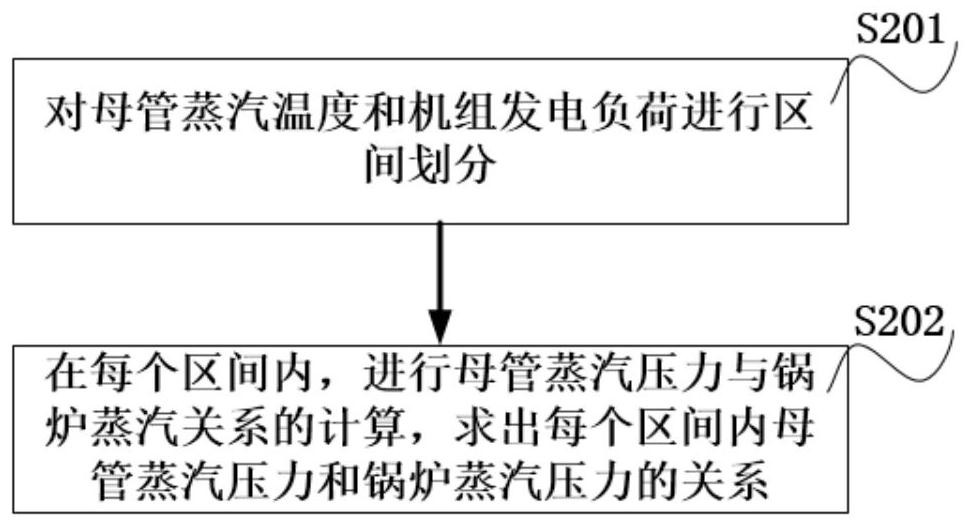

[0138] Step S02: Calculate the relationship between the steam pressure of the main pipe and the steam pressure of the boiler;

[0139] Step S03: Polling and recursively assigning parent pipe parameters;

[0140] Step S04: Allocate boiler parameters.

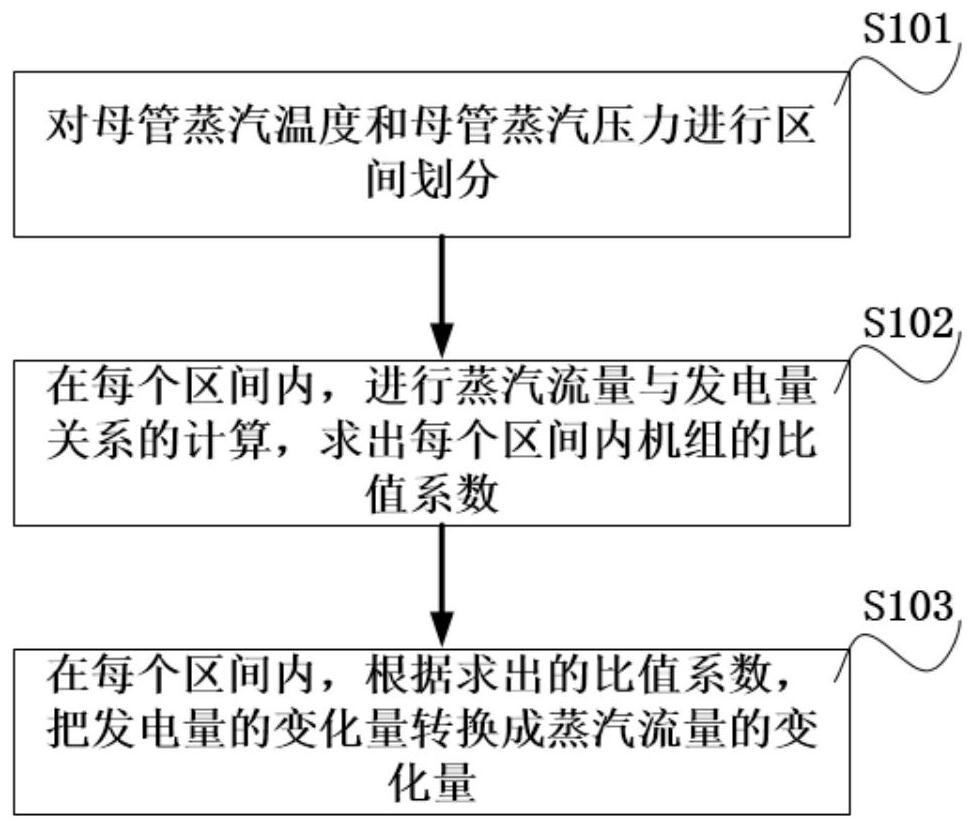

[0141] Further, the step S01 includes the following calculations:

[0142] Step S101: Carry out interval division for the steam temperature of the main pipe and the steam pressure of the main pipe.

[0143] T and P are further divided into working intervals. For example: T is divided into 4 intervals, and P is divided into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com