Electroplating layer for terminal and terminal thereof

A technology of electroplating and plating, applied in contact parts and other directions, can solve the problems affecting the service life of smart devices, the terminal corrosion of the interface, and the high cost, and achieve outstanding electrolytic resistance, wear resistance and corrosion resistance. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

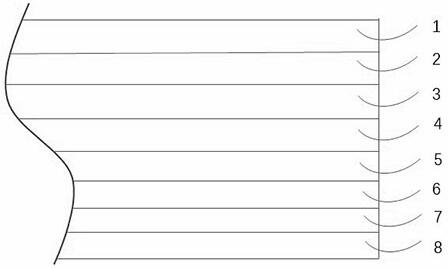

[0018] Such as figure 1 As shown, an electroplating layer for a terminal 8 includes a copper plating layer 7 electroplated on the surface of the terminal 8, and the surface of the copper plating layer 7 is sequentially electroplated with an inner nickel plating layer 6, an inner gold plating layer 5, an inner platinum plating layer 4, and an outer nickel-tungsten plating layer. Coating 3, Outer Gold Coating 2 and Outer Platinum Coating 1. Since the terminal 8 is made of copper material to provide the signal transmission performance and electrical conductivity of the terminal 8; a layer of copper plating layer 7 is electroplated on the surface of the terminal 8, which can be closely combined with the terminal 8, and at the same time a relatively flat electroplating layer is formed on the surface of the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com