Piezoelectric ultrasonic dispersion disinfection mechanism and use method thereof

A piezoelectric ultrasonic, body technology, used in disinfection, dryers, non-progressive dryers, etc., can solve the problem that the spray atomization range cannot be adjusted according to actual needs, the atomization efficiency is low, and the pressure tank disinfectant is sterilized. problems, to achieve the effect of facilitating disinfection or drying, ensuring the effect of atomization, and ensuring the processing efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

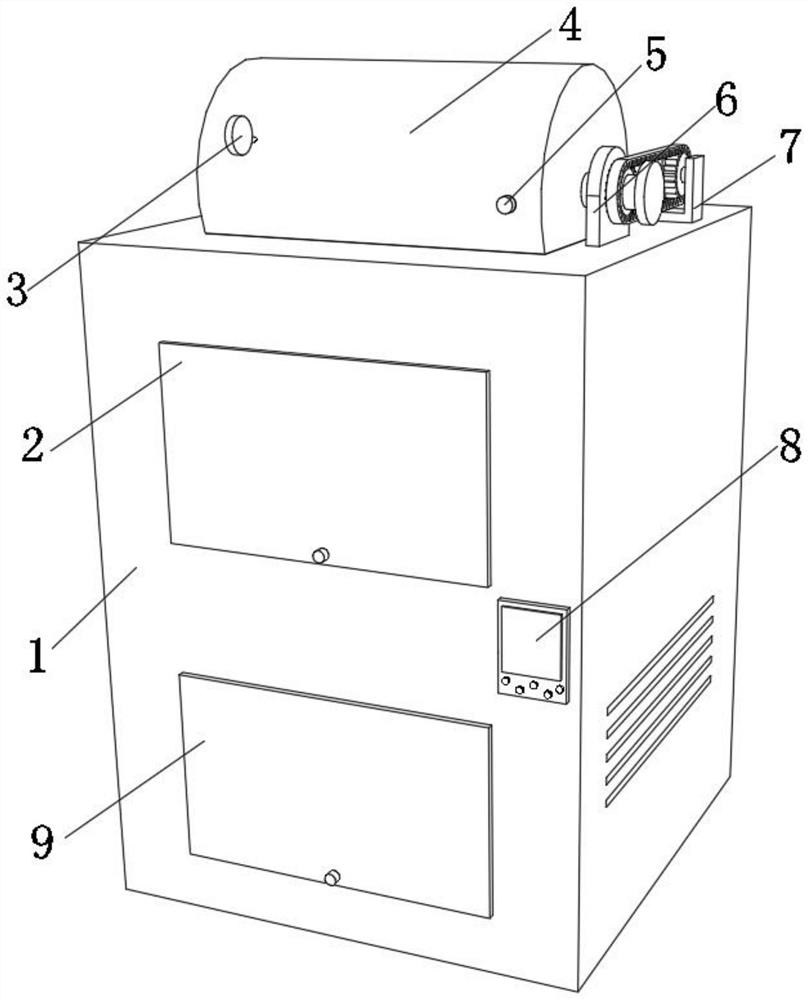

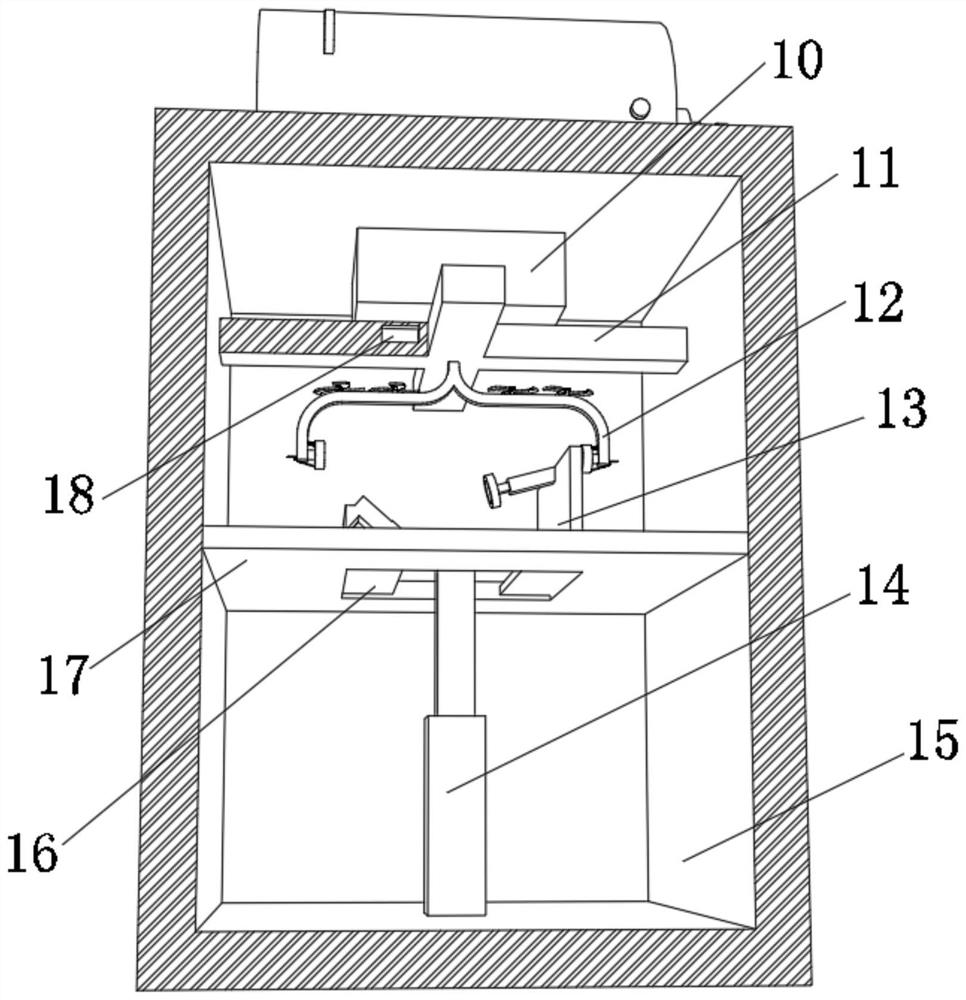

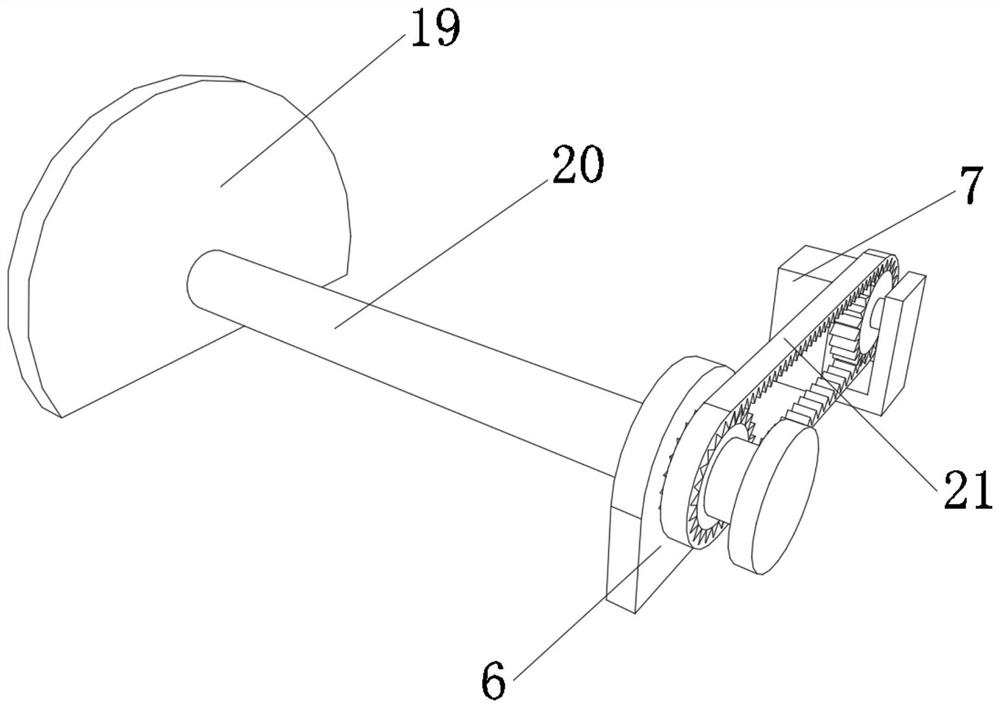

[0037] A piezoelectric ultrasonic diffusion disinfection mechanism, such as Figure 1-5 As shown, it includes a body 1, the top outer wall of the body 1 is fixed with a liquid storage box 4 by bolts, and the inner wall of the liquid storage box 4 is provided with a pressure-applying structure; the bottom inner wall of the body 1 is provided with a drying chamber 15, and the body 1 The inner wall of one side of 1 is fixed with a partition plate 17 by bolts, and the inner wall of the opposite side of the partition plate 17 is provided with an electric telescopic plate 16. In the upper atomization chamber, the inner wall of one side of the body 1 is fixed with a connecting seat 11 by bolts, and the top outer wall of the connecting seat 11 and the top inner wall of the body 1 are fixedly connected with the same atomizing generator 10, and the atomizing generator 10 Including piezoelectric sheets, etc., citing the prior art, so it will not be stated again, the bottom outer wall of ...

Embodiment 2

[0052] A method for using the piezoelectric ultrasonic dispersion disinfection mechanism described in Embodiment 1, such as Figure 1-5 shown, including the following steps:

[0053] S1: Open the box door 1, place the items to be processed on the mounting plate 13 through the object positioning structure to limit the range of activities;

[0054] S2: Using the cooperation of the positioning pin 27 and the tightening belt 26, adjust the nozzle angle of the nozzle 24 towards the article;

[0055] S3: Close the box door 1, and set the disinfection and drying standards through the controller 8;

[0056] S4: The spray structure in the atomization chamber performs a comprehensive disinfection treatment on the items without dead ends;

[0057] S5: After the disinfection is completed, the top support member 14 is manipulated to transfer the articles to the drying chamber 15 for drying treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com