Beneficiation thickener with defoaming device

A technology of defoaming device and thickener, which is applied to the feeding/discharging device of the sedimentation tank, foam dispersion/prevention, separation method, etc., can solve the problems of reducing the efficiency of the thickener and slowing down the particle settling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

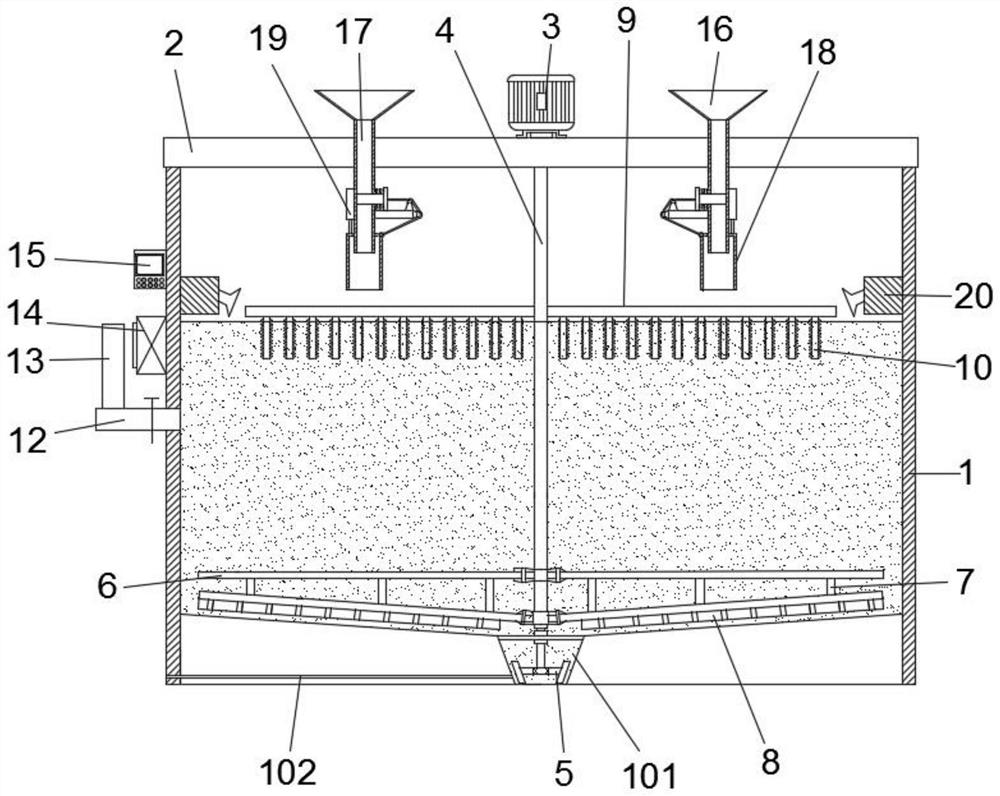

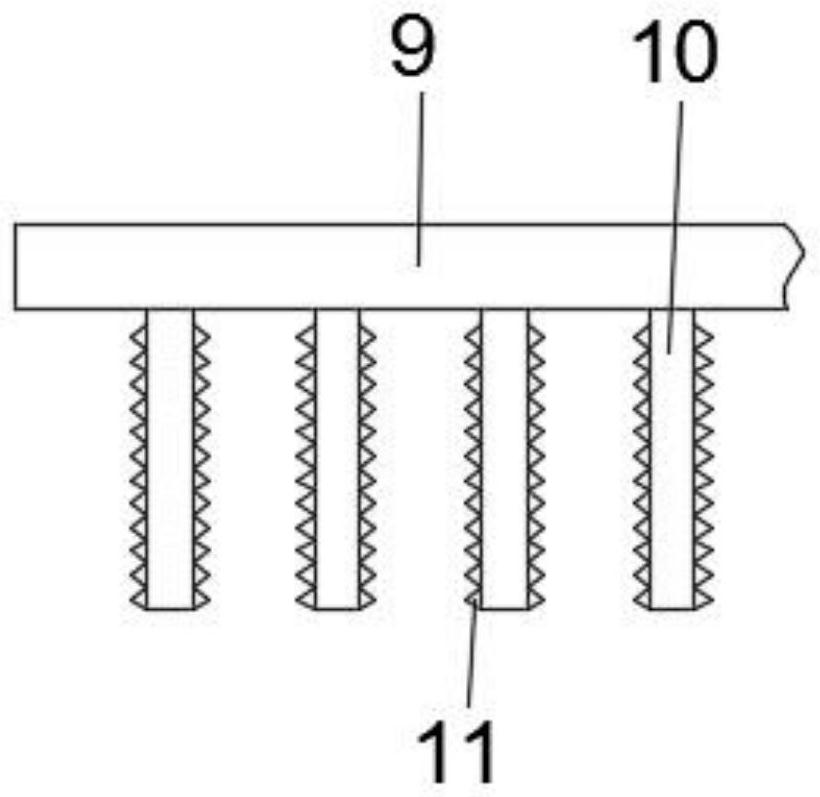

[0031] Such as Figure 1-3 As shown, a thickener for beneficiation with a defoaming device, including

[0032] Thickener body 1, the bottom of the thickener body 1 is provided with a discharge hopper 101, and one side of the discharge hopper 101 is provided with a discharge trough 102, and the top of the thickener body 1 is fixedly installed with a beam 2, and the top of the beam 2 A motor 3 is fixedly installed on the side, the output shaft of the motor 3 runs through the beam 2 and a rotating shaft 4 is fixedly installed, the bottom end of the rotating shaft 4 extends into the discharge hopper 101 and a stirring blade 5 is fixedly installed,

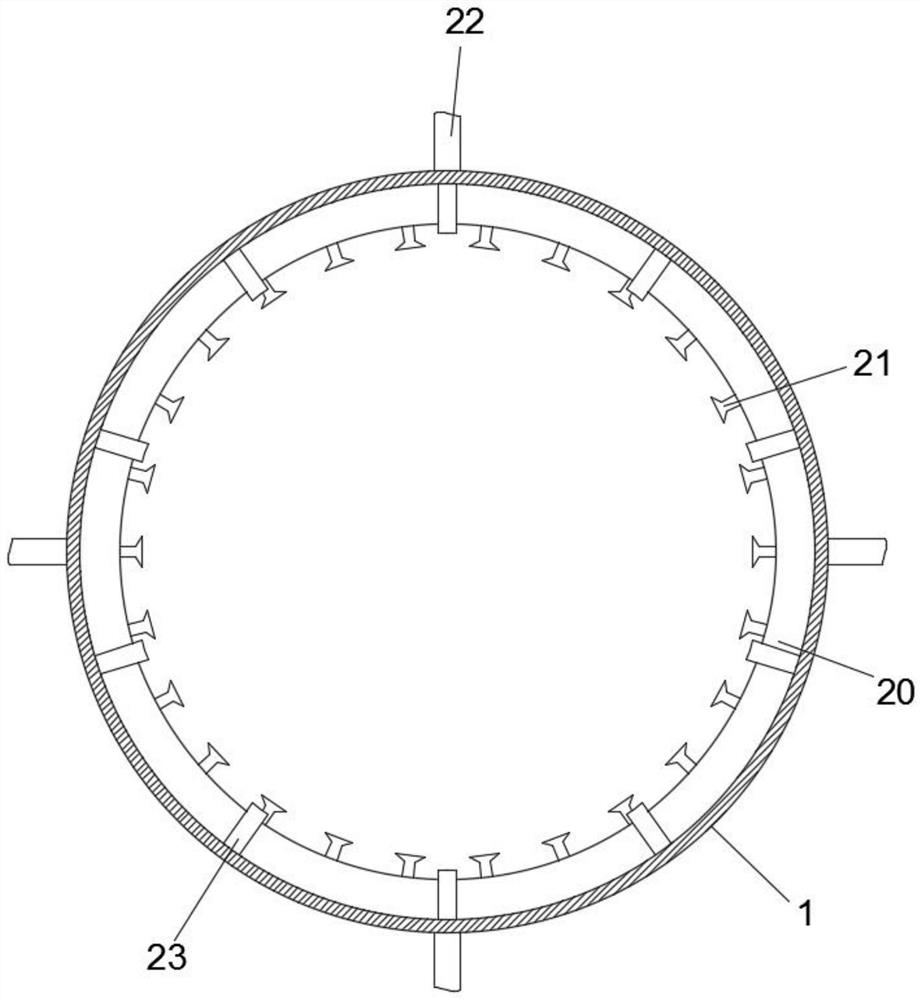

[0033] Bubble-gathering assembly, the bubble-gathering assembly includes water outlet pipe 20, nozzle 21 and water inlet pipe 22, and the top of the inner wall of the thickener body 1 is fixed with a ring-shaped water outlet pipe 20, and the water outlet pipe 20 is far away from the thickener body 1- Several groups of nozzles 21 are a...

Embodiment 2

[0043] On the basis of Example 1, such as Figure 4-6 As shown, the similarities will not be repeated, and the difference is that a sludge bucket 16 is provided on the top of the beam 2, and a feed pipe 17 is fixedly installed at the bottom of the sludge bucket 16, and the bottom end of the feed pipe 17 is Through the beam 2 and fixedly connected with it, the bottom end of the feed pipe 17 is sleeved with a telescopic pipe 18, and the side wall of the feed pipe 17 is fixedly equipped with an electric push rod 19, and the telescopic end of the electric push rod 19 is connected to the Telescopic tube 18 tops are fixedly connected.

[0044] A guide plate 25 is fixedly installed on the side of the feed pipe 17 away from the electric push rod 19, and a first guide pulley 26 is installed on the end of the guide plate 25 away from the side wall of the feed pipe 17, and a guide pulley 26 is installed on the upper side of the guide plate 25. The second guide pulley 27, the inside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com