Medicament mixing device for medicament production and processing

A mixing device and medicament technology, applied in mixers, mixers with rotating containers, transportation and packaging, etc., can solve problems affecting tablet weight, affecting drug powder uniformity, layering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

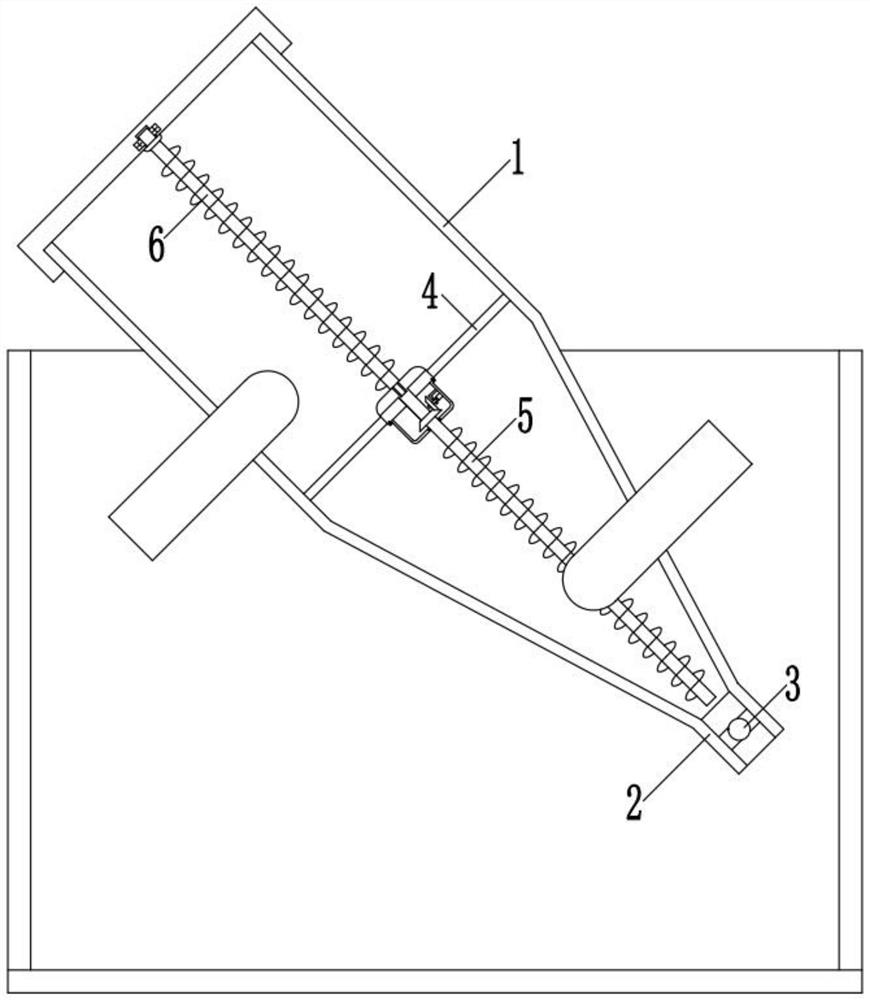

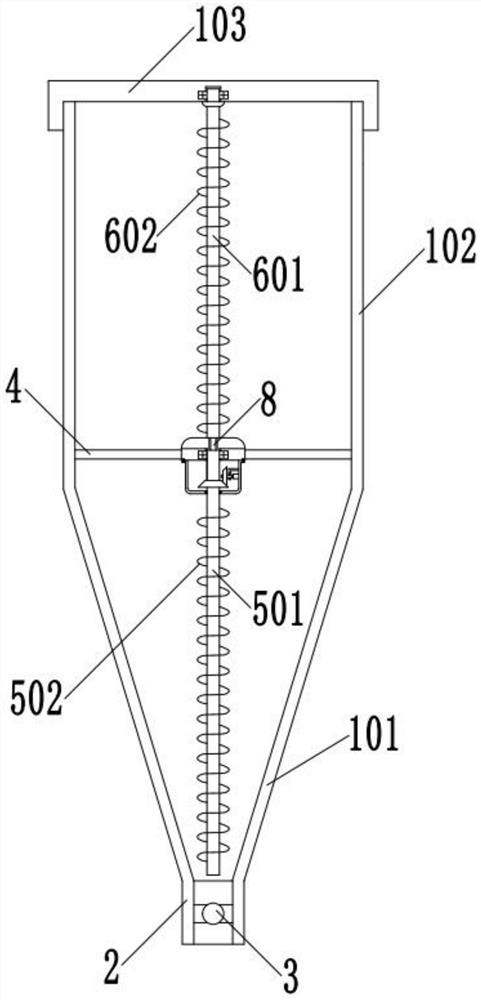

[0048] like figure 1As shown, the embodiment of the present invention provides a pharmaceutical mixing device for pharmaceutical production and processing, including a cylinder body 1, which is fixed on a three-dimensional moving arm of a three-dimensional movement mixer; the cylinder body 1 includes a conical part 101, a cylindrical part 102 and a cylinder cover 103; the tapered portion 101 is fixed on a three-dimensional moving arm of the three-dimensional motion mixer, the lower end of the tapered portion 101 is fixed with a discharge pipe 2, and the discharge pipe 2 is provided with a valve 3; the The upper end of the conical part 101 is fixedly connected with the lower end of the cylindrical part 102, the cylindrical part 102 is fixed on another three-dimensional moving arm of the three-dimensional motion mixer, and the upper end of the cylindrical part 102 is detachably connected with the cylinder cover 103; the support 4, Fixed at the lower end of the inner side of the ...

Embodiment 2

[0054] This embodiment is based on Embodiment 1. The first propeller 5 includes a first rotating shaft 501 and a first helical blade 502 fixed on the side wall of the first rotating shaft 501; the upper end of the first rotating shaft 501 is connected to the first rotating shaft 501 through a bearing. - the support 4 is connected;

[0055] The second propeller 6 includes a second rotating shaft 601 and a second helical blade 602 fixed on the side wall of the second rotating shaft 601; the lower end of the second rotating shaft 601 is fixed with a spline 7, and the spline 7 is connected to the first rotating shaft. The spline groove 8 opened on the upper end of 501 is adapted; the upper end of the second rotating shaft 601 is connected to the cylinder cover 103 through a bearing.

[0056] Further, the support member 4 includes a disk 401, the upper end of the first rotating shaft 501 penetrates the disk 401, and the side wall of the first rotating shaft 501 is connected with th...

Embodiment 3

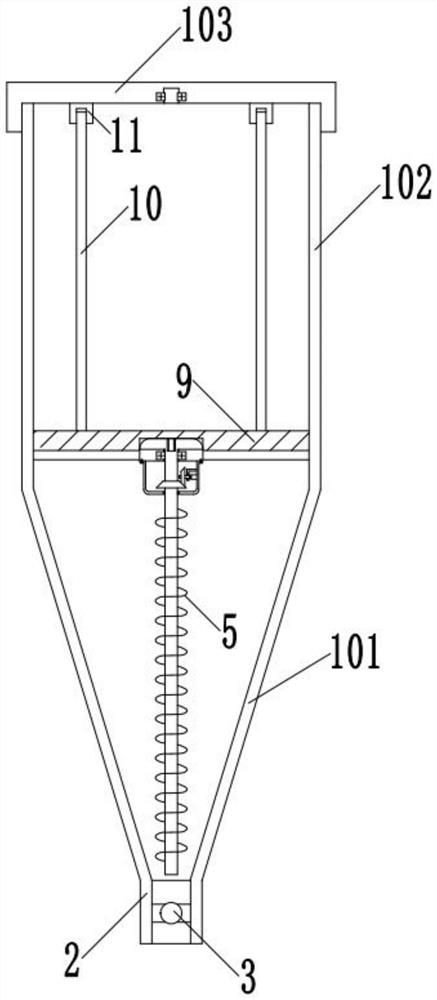

[0060] This embodiment is based on Embodiment 2. The partition assembly includes a partition plate 9, the partition plate 9 is a disc-shaped structure, and the outer diameter of the partition plate 9 is adapted to the inner diameter of the cylindrical portion 102; the support rod 10, the support rod The lower end of 10 is fixedly connected with the upper surface of the partition plate 9, and the upper end of the support rod 10 is provided with an external thread; the sleeve 11 is fixed on the lower surface of the cylinder cover 103, and the inner side of the sleeve 11 is provided with an internal thread, and the internal thread is connected with the inner thread. The outer thread provided on the upper end of the support rod 10 is threadedly connected.

[0061] Further, the lower surface of the partition plate 9 is provided with a groove matching with the disk 401 .

[0062] The partition assembly in the present invention adopts a detachable structure. The sleeve 11 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com