Manipulator clamp for grabbing synthetic cavity of cubic press

A technology of six-sided top press and synthesizing cavity is applied in the process of applying ultra-high pressure, the method of chemically changing substances by using atmospheric pressure, chemical instruments and methods, etc., which can solve the problem of poor use effect and unexpected situations. To deal with problems such as poor effect and complex control process, to avoid the trouble of wrong feeding, improve the control effect, and ensure the effect of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

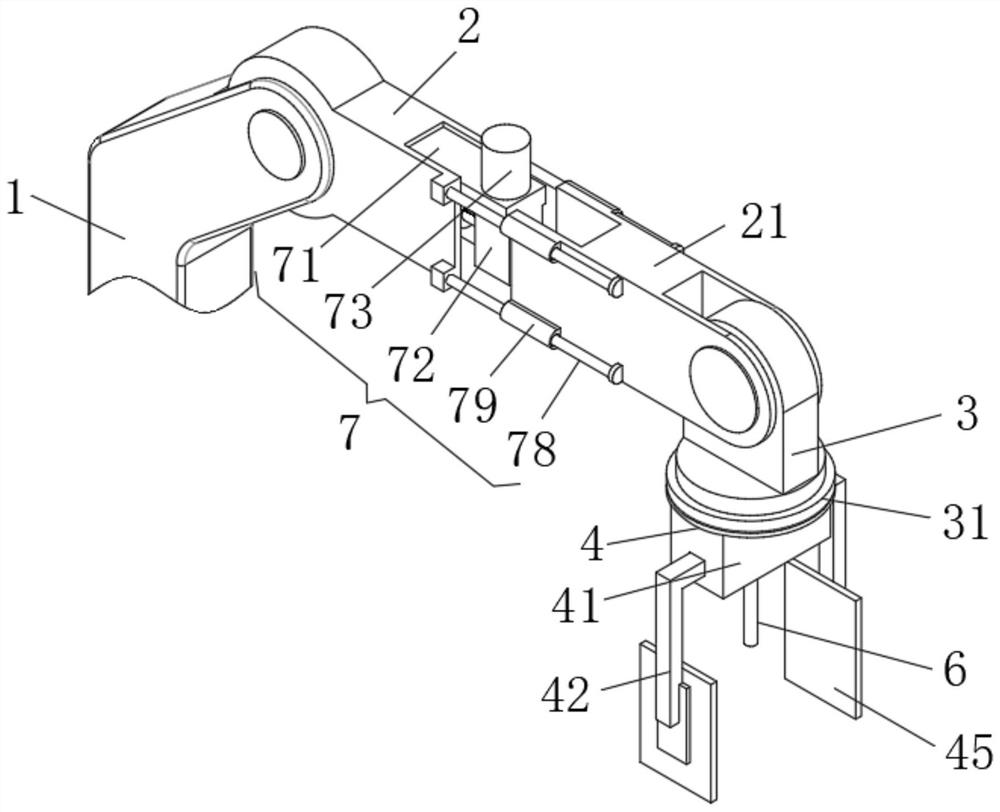

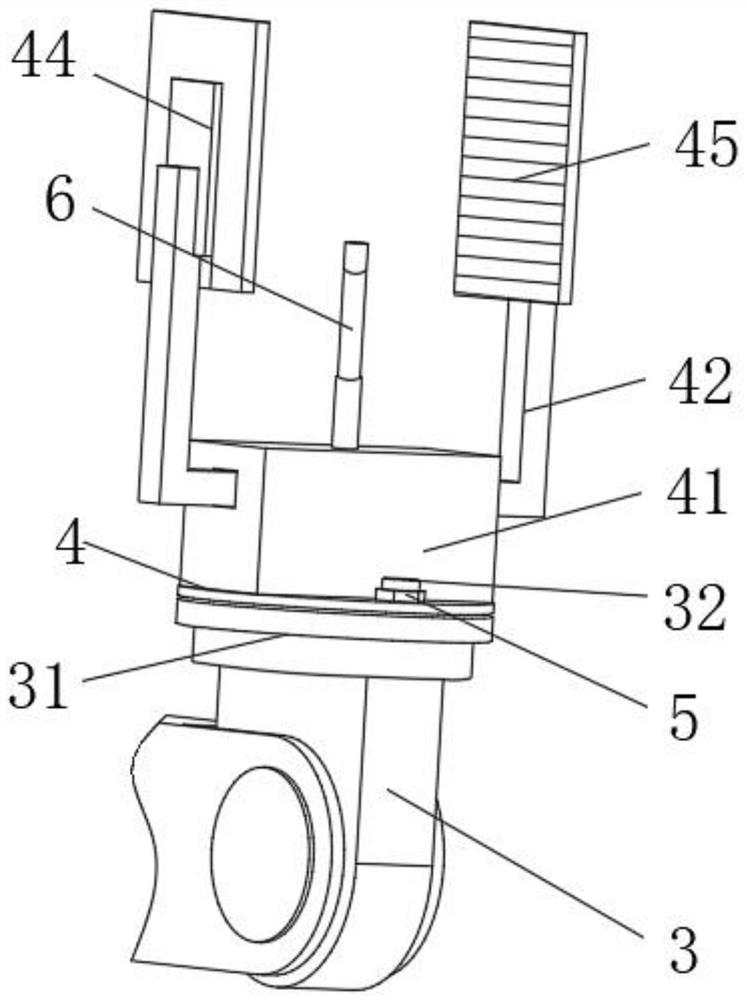

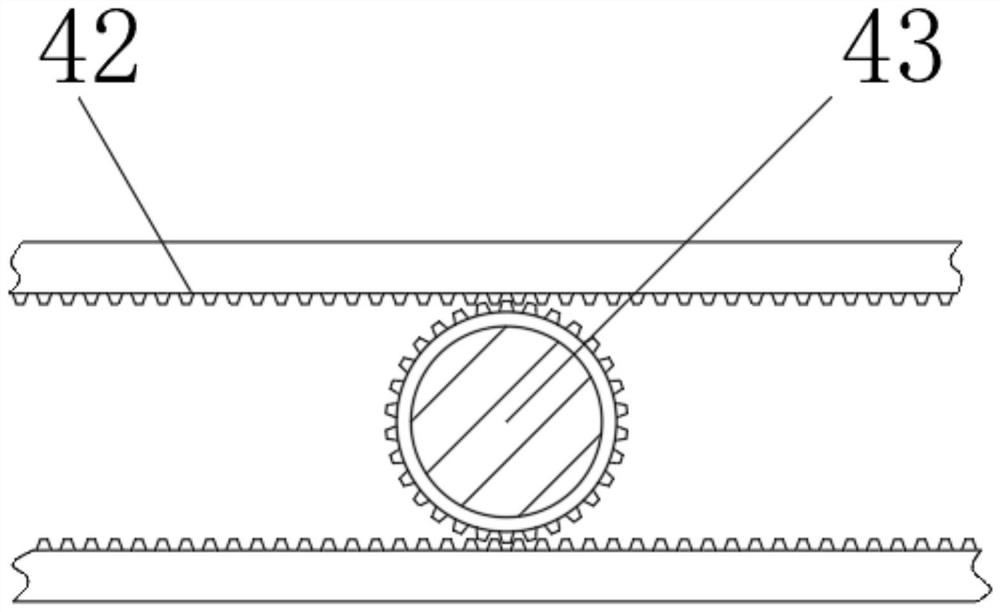

[0033] see Figure 1-5 , a manipulator fixture for grabbing the composite cavity of a six-sided top press, comprising a support arm 1, the external rotation of the support arm 1 is connected with a connecting arm 2, and the external part of the connecting arm 2 is movably connected with an extension arm 21, and the connecting arm 2 and the extension arm 21 is provided with an extension mechanism 7, the movable end of the extension arm 21 is rotatably connected with the movable arm 3, and the end of the movable arm 3 is rotatably connected with the rotary platform 31, and the exterior of the rotary platform 31 is fixedly connected with two sets of positioning Pin 32, the outside of rotary table 31 is movably connected with mounting plate 4, the outside of mounting plate 4 is fixedly connected with drive block 41, the outside of drive block 41 is movably connected with drive rod 42, and the outside of drive block 41 is provided with induction mechanism 6.

[0034] Among them, be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com