Dust removal type cloth winding equipment suitable for detection operation

A technology of cloth rolls and equipment, applied in the direction of cleaning methods using gas flow, analytical materials, measuring devices, etc., can solve problems such as large workload, detection errors, dust pollution, etc., and achieve the effect of simple disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

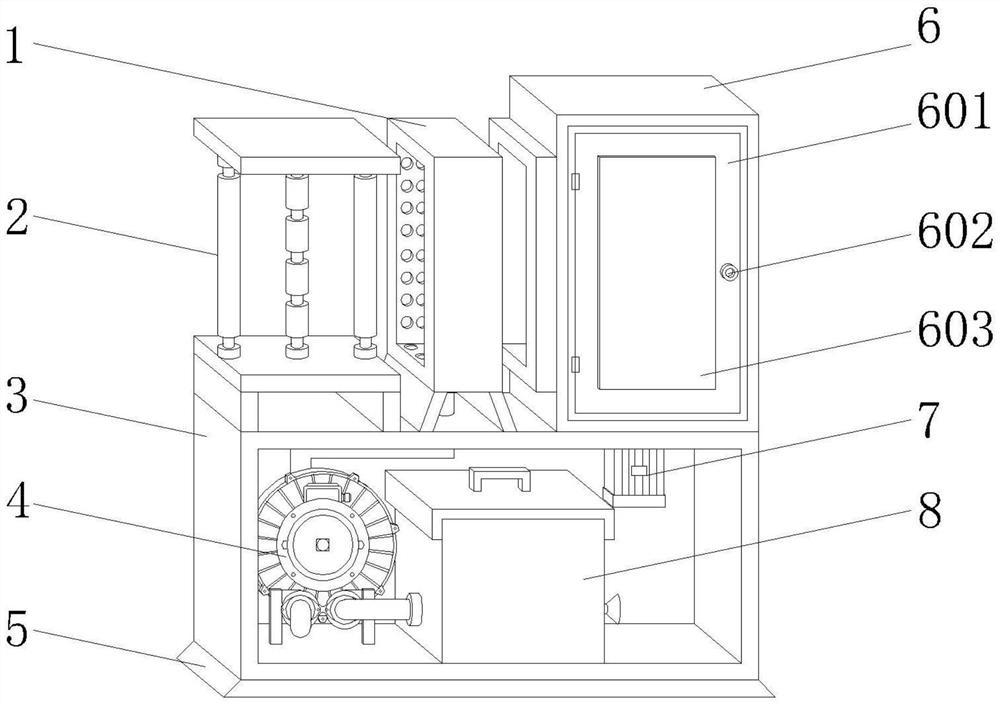

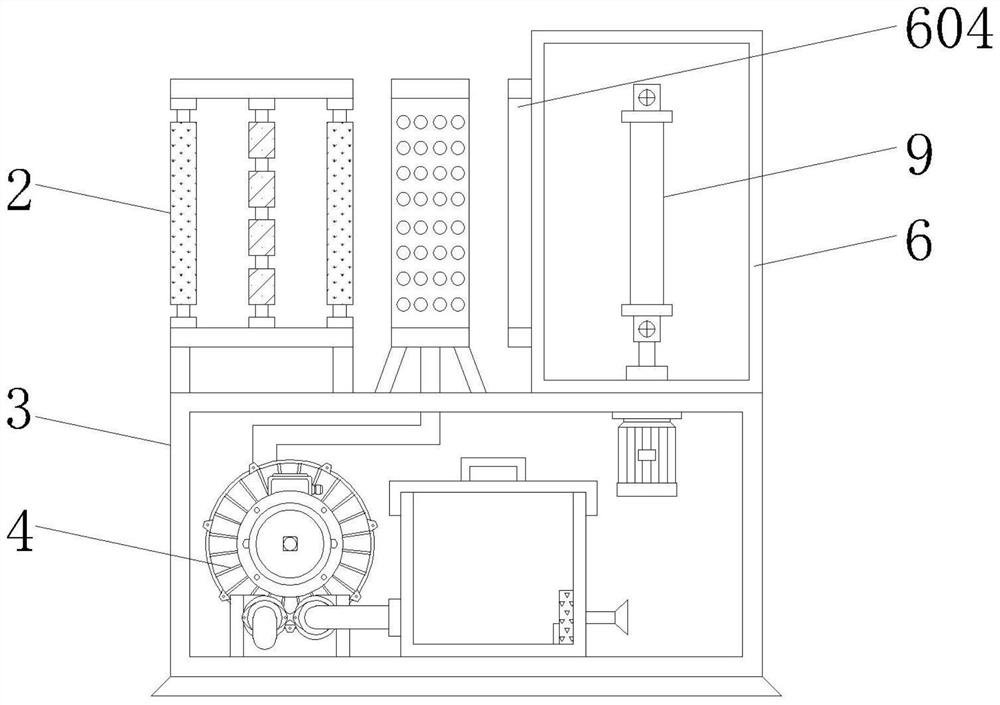

[0032] see Figure 1-6 , a kind of dust-removing cloth retracting equipment suitable for detection operation provided by the present invention comprises a dust suction chamber 1, a storage rack 3 and a collection tank 8, the bottom of the storage rack 3 is fixedly installed with a base 5, and the top of the storage rack 3 is fixed A guide assembly 2 is installed, and the guide assembly 2 includes connecting plates 201, rotating shafts 204 are installed equidistantly between the connecting plates 201, hair-sticking rollers 203 are installed equidistantly between the rotating shafts 204, and guide rollers are fixedly installed between the hair-sticking rollers 203 202, the bottom of the connection plate 201 is equidistantly installed with a second support plate 205;

[0033] Specifically, such as figure 1 and Figure 4 As shown, during use, by fixedly installing the guide assembly 2 on the top of the storage rack 3, the rotating shaft 204 can be used to assist the guide roller...

Embodiment 2

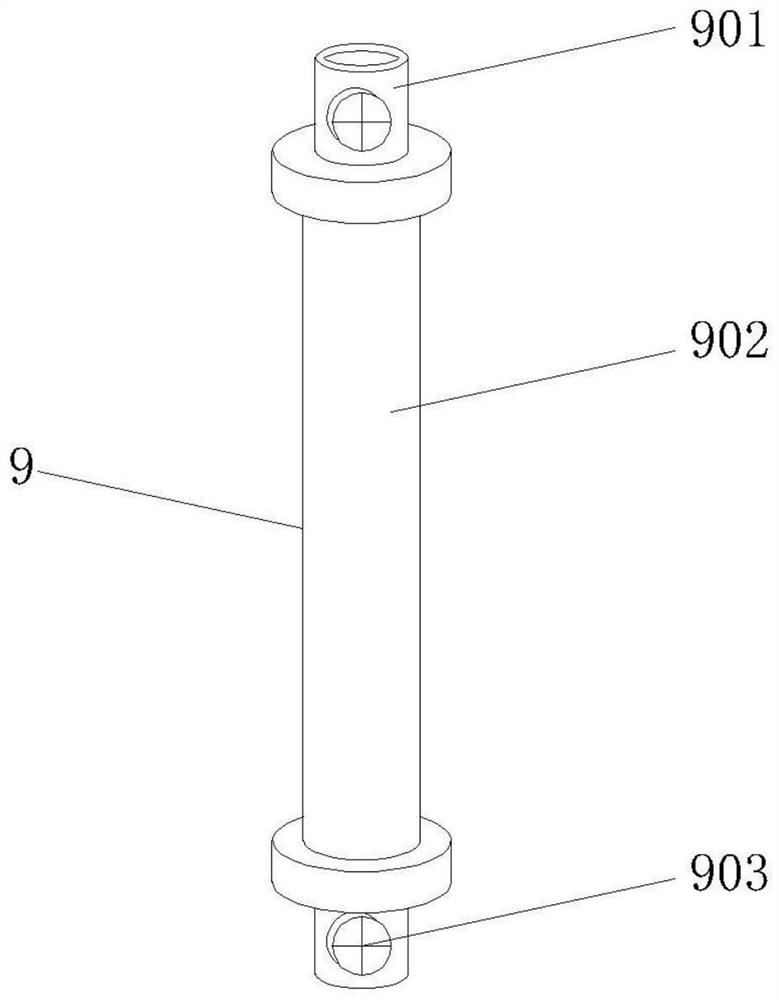

[0042] The structure of the dust-removing type cloth retracting device suitable for detection operation in this embodiment is basically the same as that of the dust-removal type cloth retraction device applicable to detection operation in Embodiment 1. One-way valve 10, the three-way valve 10 itself has three-way conduction performance, and can be electrically controlled with an external controller. Any output end of the three-way valve 10 is connected to the input end of the vacuum cleaner 4, and the three-way valve 10 The other output end of the vacuum cleaner is equipped with a detection tube 12. When the vacuum cleaner 4 needs to perform suction operation, it is necessary to open the connection between the three-way valve 10 and the vacuum cleaner 4. In certain cases, in order to avoid the vacuum cleaner 4 The internal composition is complex or there are components such as engine oil that affect the dander detection, the switch between the three-way valve 10 and the detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com