Thiadiazole lubricating oil anti-wear additive and preparation method thereof

A lubricating oil additive, lubricating oil technology, applied in the directions of additives, lubricating compositions, petroleum industry, etc., can solve the problems of difficult and widely used, poor oil solubility, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

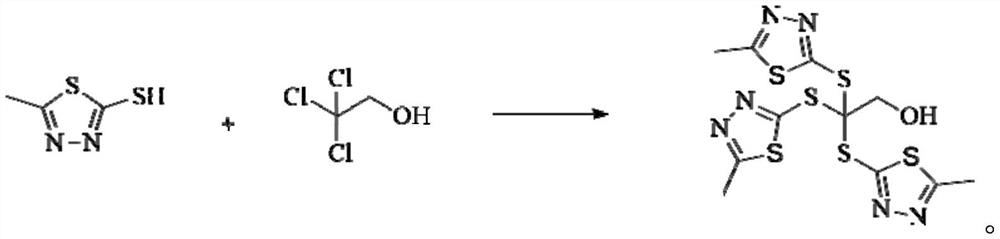

[0015] Add 0.3 mol of 5-methyl-2-mercaptothiadiazole to the three-necked flask, then add 0.3 mol of sodium hydroxide and 100 mL of distilled water to the system, slowly raise the temperature to 70°C, and maintain the temperature and stir for 1 hour; After all the solids in the system are dissolved, add 0.1 mol of 2,2,2-trichloroethanol, maintain the temperature and stir the reaction for 4 hours; after stopping the reaction, wash the reaction solution with hot water to remove water-soluble impurities, and extract it with dichloromethane. The organic layer was collected, and the solvent was distilled off under reduced pressure to obtain a light yellow solid product, which was the target product of the additive.

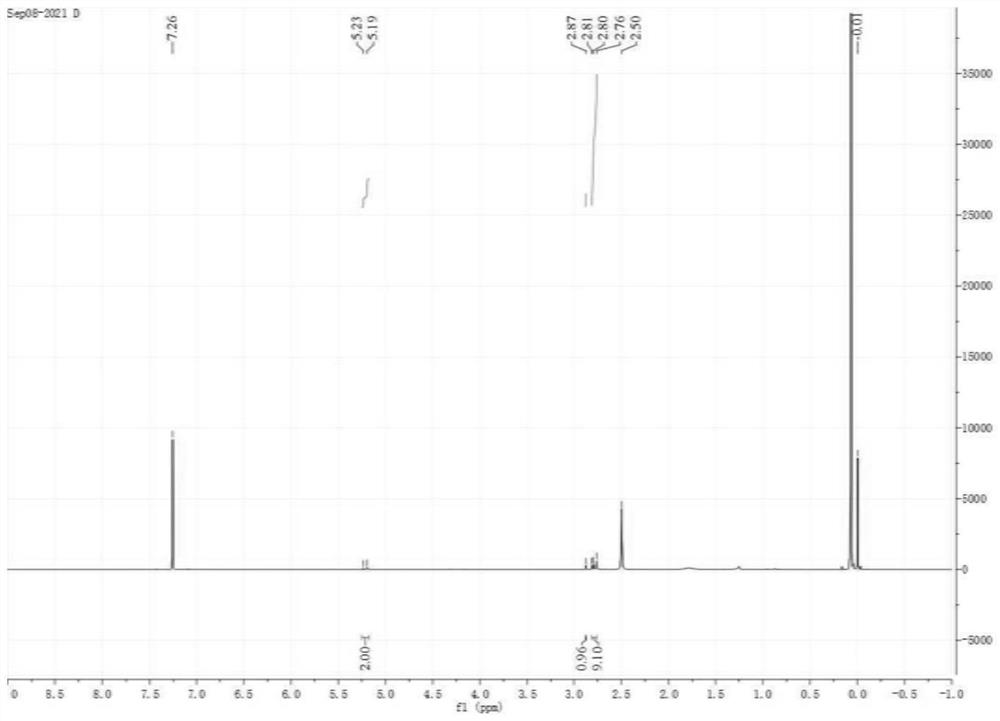

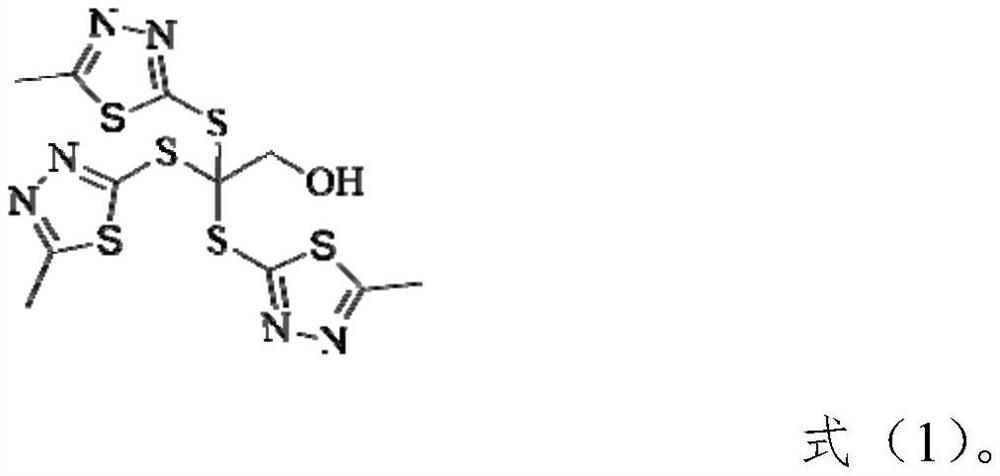

[0016] The target product was identified as 2,2,2-tris((5-methyl-1,3,4-thiadiazol-2-yl)thio)ethanol by H NMR spectrum. figure 1 .

Embodiment 2

[0018] Add 0.15 mol of 5-methyl-2-mercaptothiadiazole to the three-necked flask, then add 0.15 mol of sodium hydroxide and 50 mL of distilled water to the system, slowly raise the temperature to 70°C, and maintain the temperature and stir for 0.5 hours; After all the solids in the system are dissolved, add 0.05mol of 2,2,2-trichloroethanol, keep the temperature and stir the reaction for 3 hours; after stopping the reaction, wash the reaction liquid with hot water to remove water-soluble impurities, extract with dichloromethane, The organic layer was collected, and the solvent was distilled off under reduced pressure to obtain a light yellow solid product, which was the target product of the additive.

[0019] The target product was identified as 2,2,2-tris((5-methyl-1,3,4-thiadiazol-2-yl)thio)ethanol by H NMR spectroscopy.

Embodiment 3

[0021] Add 0.06 mol of 5-methyl-2-mercaptothiadiazole to the three-necked flask, then add 0.06 mol of sodium hydroxide and 20 mL of distilled water to the system, slowly raise the temperature to 65°C, and maintain the temperature and stir for 0.5 hours; After all the solids in the system are dissolved, add 0.02mol of 2,2,2-trichloroethanol, keep the temperature and stir the reaction for 3 hours; after stopping the reaction, wash the reaction liquid with hot water to remove water-soluble impurities, extract with dichloromethane, The organic layer was collected, and the solvent was distilled off under reduced pressure to obtain a light yellow solid product, which was the target product of the additive.

[0022] The target product was identified as 2,2,2-tris((5-methyl-1,3,4-thiadiazol-2-yl)thio)ethanol by H NMR spectroscopy.

[0023] Tribological performance evaluation

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com