Beam type regenerative buffer guardrail

A guardrail and beam-type technology, applied in the field of beam-type regenerative buffer guardrails, can solve the problems of large distance between the corrugated beam guardrail and the ground, vehicles are easy to cross or break the guardrail, and the blocking function is weak, and achieves low cost, small deformation, and production. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

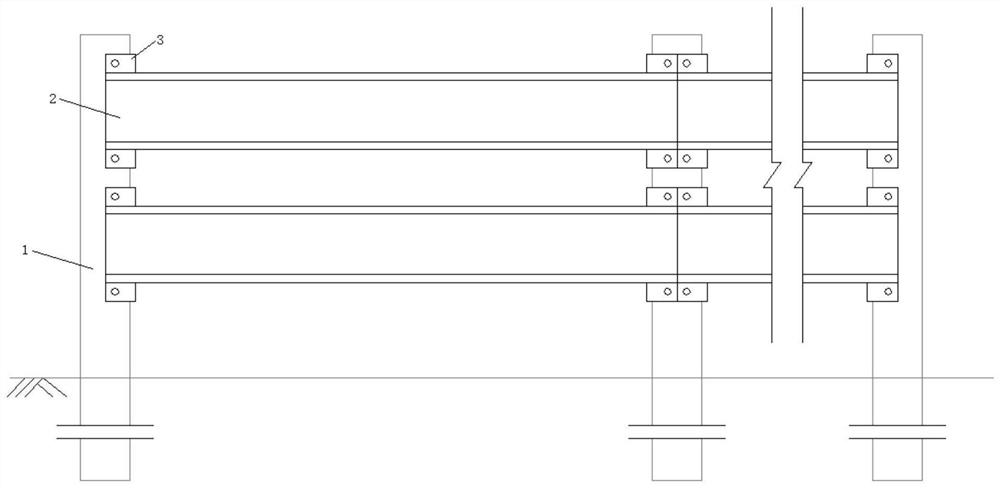

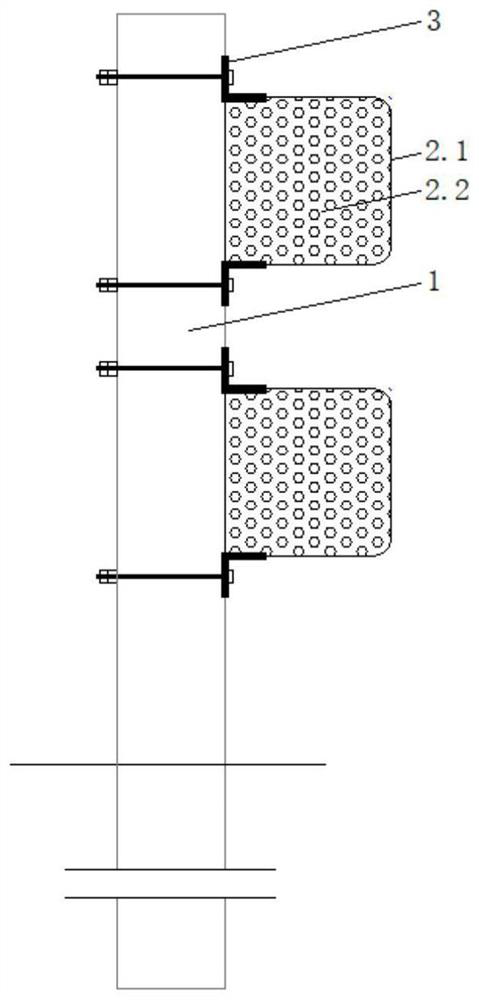

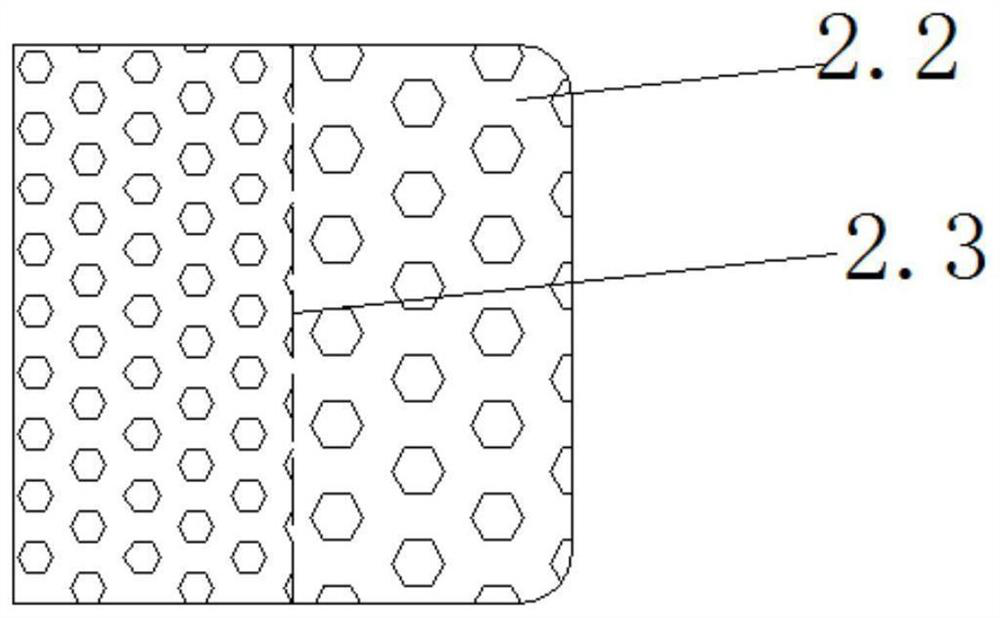

[0021] Such as figure 1 and figure 2 The shown buffer guardrail for preventing vehicle rollover includes two support columns 1 and at least one buffer beam 2 parallel to each other. The two support columns 1 are respectively arranged at both ends of the buffer beam 2. Arranged at intervals, and the two ends of the buffer beam 2 are fixedly connected to the support column 1; the buffer beam 2 includes a recycled buffer energy-absorbing material 2.2 and a shell 2.1, and the recycled buffer energy-absorbing material 2.2 is prepared from construction waste. As a result, the regenerative buffer energy-absorbing material 2.2 is filled inside the housing 2.1 to form the buffer beam 2, and the housing 2.1 is fixedly connected to the support column 1.

[0022] Preferably, the housing 2.1 is made of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com