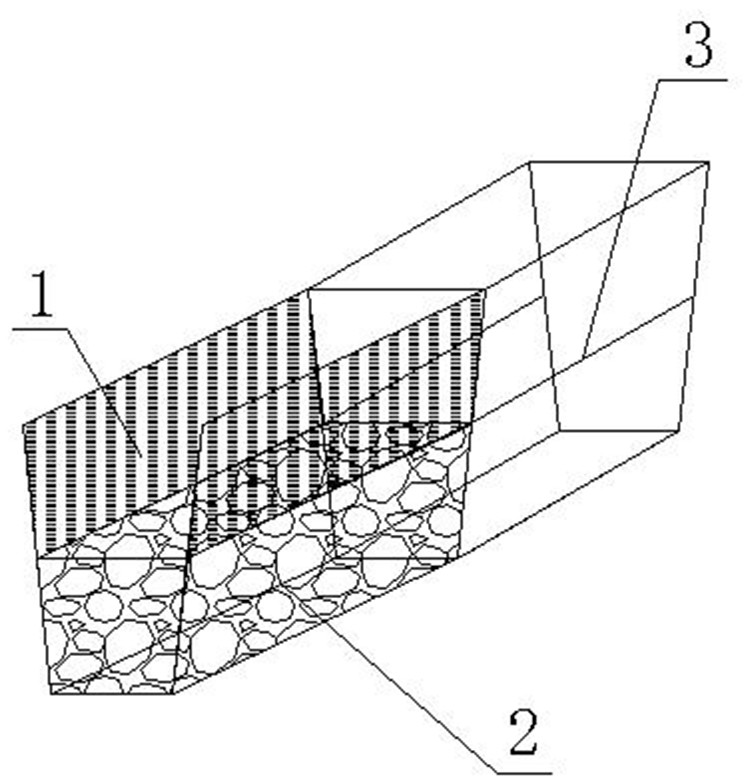

Long-distance deep and narrow pipe ditch stonework excavation and protection method

A ditch and long-distance technology, which is applied in the field of long-distance deep and narrow pipe trench excavation and protection, can solve the problems of difficulty in controlling the direction of flying stones, can not meet the needs of use, low construction efficiency, etc. Excavation construction efficiency, easy control, and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1, please refer to Figure 5 , and its construction method is described as follows:

[0038] (1) On-site site selection. Based on the construction drawings and actual site conditions, determine the site for the blasting test with the consulting engineer and the owner. The site is required to be in a relatively wide area with few residents and buildings, so as to facilitate the construction of the test section.

[0039] (2) According to the reported construction plan and planned length of the test section, determine the actual length of the test section. After communicating with the consulting engineer, the length of the test section is finally determined to be 30m.

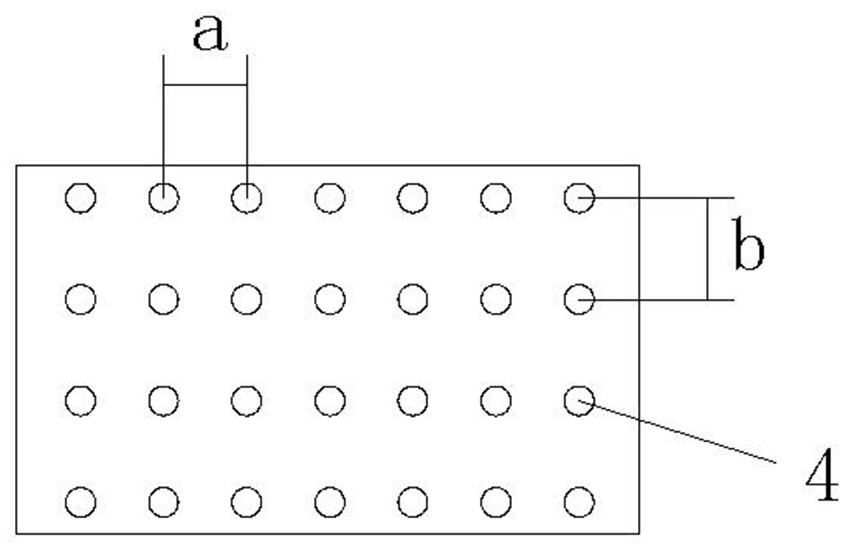

[0040] (3) According to the reported test section plan and the actual situation on site, determine the parameters of the blasting construction. The total length of the test section is 30m. The hole row spacing is divided into 0.4m, 0.5m, and 0.6m respectively, and the blasting construction of the t...

Embodiment 2

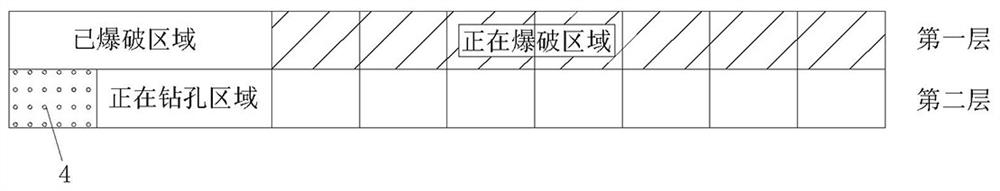

[0045] (8) The test section adopts this method for construction, which can speed up the construction speed on the premise of ensuring the construction quality of deep and narrow pipe trenches. Engineering input. Example 2, please refer to Image 6 , and its construction method is described as follows:

[0046] A: Current situation investigation: Through the construction drawings, first conduct surveys at the construction site of the deep and narrow pipe trench to find out the existing underground pipelines and other pre-embedded equipment. Determine whether the pipeline position in the current drawing design is reasonable and whether it needs to be adjusted. Areas with dense population and many buildings in the construction area should be investigated as a key point; because there are no detailed drawings of underground pipelines in some parts, there are many unknown situations, and it is impossible to judge the risks existing in the construction process, so the current situ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap