Method for repairing high-abrupt-slope rock mass through RFP component and thick-layer base material spray-seeding combined technology

A combined process and steep slope technology, applied in planting substrates, infrastructure engineering, botanical equipment and methods, etc., can solve problems such as loss of water and soil conservation capacity, low vegetation coverage, and loss of ecological functions, so as to reduce construction difficulty and reduce vegetation loss. High coverage, anti-weather peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

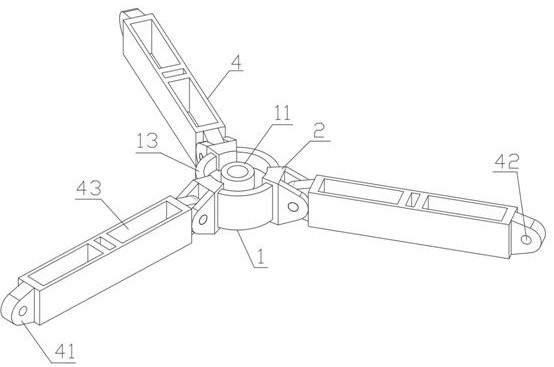

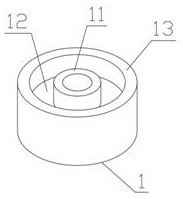

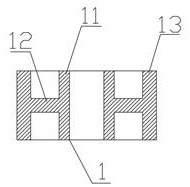

[0083] like figure 1 , 2 , 3, 4, 6, 7, 8, 9, an RFP component, including a fixed connector 1, a first slider 2, a first leg 4, an anchor rod fixing assembly 8 and a shaft;

[0084] The fixing connector 1 includes a fixing column 11, a connecting plate 12 is fixedly connected to the outer wall of the fixing column 11, and a sliding rail 13 is fixedly connected to the outer wall of the connecting plate 12; the fixing column 11 is provided with an anchor rod through hole;

[0085] One end of the first sliding block 2 is fixedly connected with a first card slot 21, the other end is fixedly connected with a first connecting groove 22, and two sides of the first connecting groove 22 are provided with sliding block connecting holes 23;

[0086] Both ends of the first leg 4 are respectively fixedly connected with first connecting ears 41 , the first connecting ears 41 are provided with a leg connecting hole 1 42 , and the first leg 4 is also provided with a first weight reduction thr...

Embodiment 2

[0110] like figure 1 , 2 , 3, 4, 6, 7, 8, 9, an RFP component, including a fixed connector 1, a first slider 2, a first leg 4, an anchor rod fixing assembly 8 and a shaft;

[0111] The fixing connector 1 includes a fixing column 11, a connecting plate 12 is fixedly connected to the outer wall of the fixing column 11, and a sliding rail 13 is fixedly connected to the outer wall of the connecting plate 12; the fixing column 11 is provided with an anchor rod through hole;

[0112] One end of the first sliding block 2 is fixedly connected with a first card slot 21, the other end is fixedly connected with a first connecting groove 22, and two sides of the first connecting groove 22 are provided with sliding block connecting holes 23;

[0113] Both ends of the first leg 4 are respectively fixedly connected with first connecting ears 41 , the first connecting ears 41 are provided with a leg connecting hole 1 42 , and the first leg 4 is also provided with a first weight reduction thr...

Embodiment 3

[0138] like figure 2 , 3 , 5, 8, 10, 11, 12, 13, an RFP component includes a fixed connector 1, a second slider 3, a third leg 6, an anchor rod fixing assembly 8 and a shaft;

[0139] The fixing connector 1 includes a fixing column 11, a connecting plate 12 is fixedly connected to the outer wall of the fixing column 11, and a sliding rail 13 is fixedly connected to the outer wall of the connecting plate 12; the fixing column 11 is provided with an anchor rod through hole;

[0140] One end of the second sliding block 3 is fixedly connected with a second clamping slot 31, and the other end is fixedly connected with a first connecting block 32, and the first connecting block 32 is provided with a slider ball joint head groove 33;

[0141] Both ends of the third leg 6 are respectively fixedly connected with a first ball joint head 61, and a third weight reduction through hole 62 is also opened on the third leg 6;

[0142] A plurality of second sliders 3 are slidably connected t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com