Homogenizing production device for spore oil

A production device and technology for spore oil, applied in sampling devices, measuring devices, mixers with rotary stirring devices, etc., can solve problems such as prolonging the reaction time of raw materials, affecting product quality, and inability to stir materials, and reducing time , Guaranteed quality, fast mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

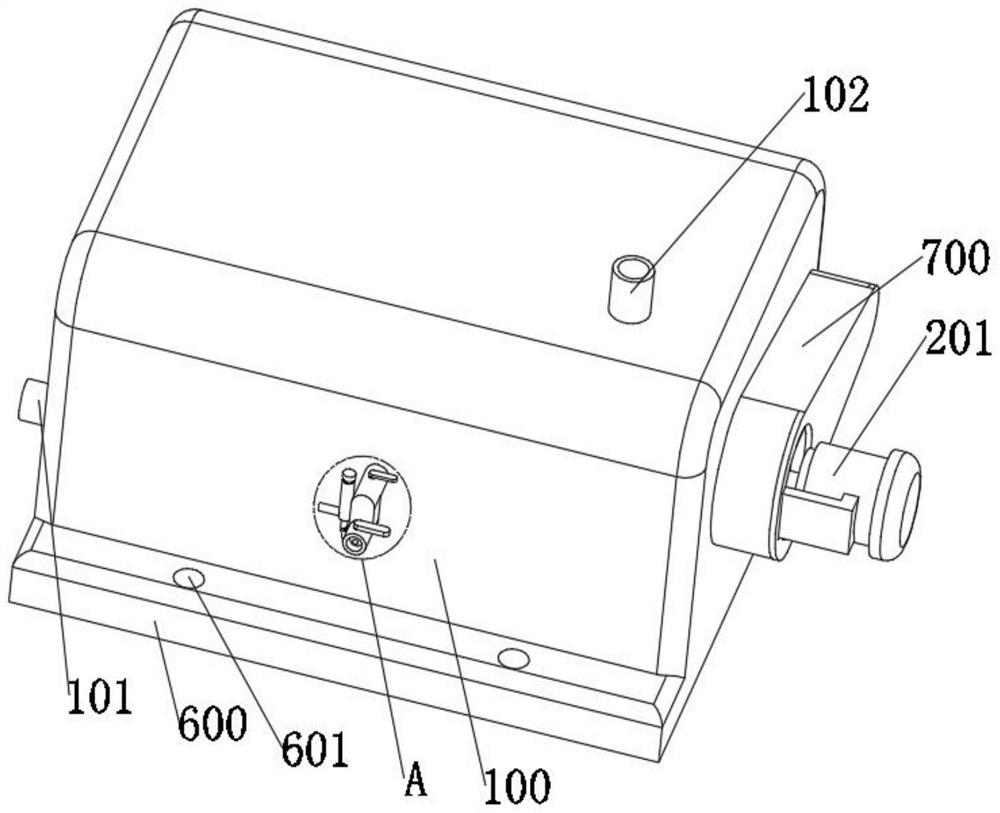

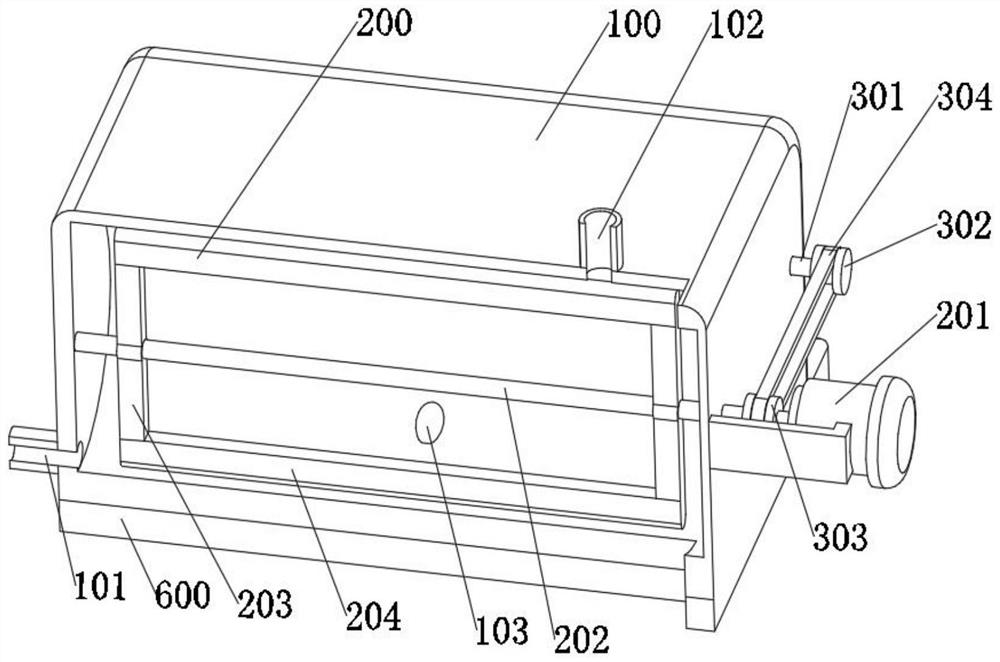

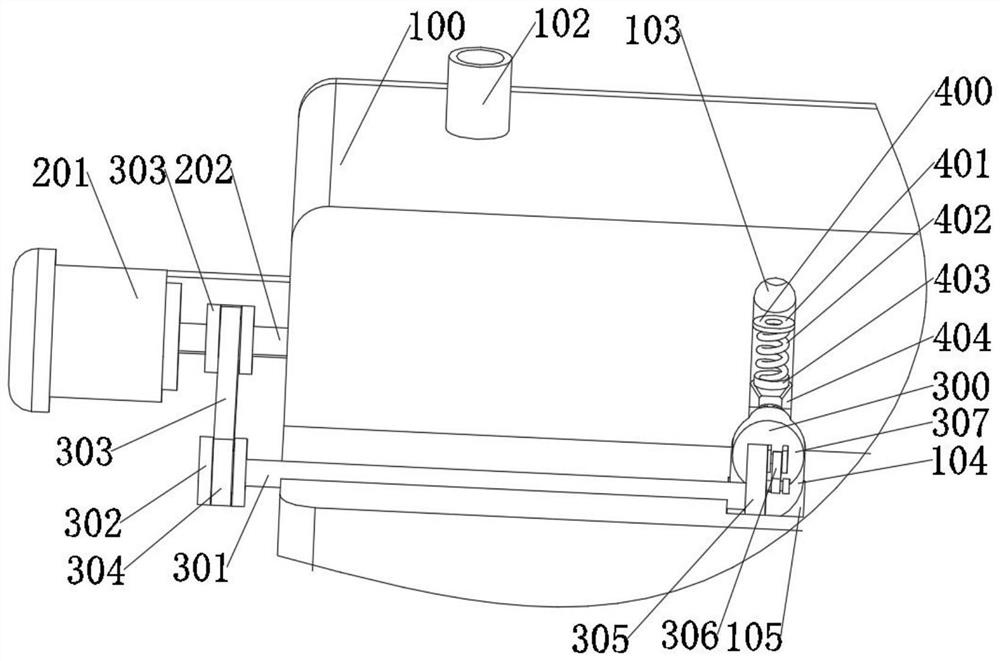

[0035] refer to Figure 1-7As shown, a homogeneous production device for spore oil includes a reactor 100, a discharge pipe 101 and a feed pipe 102. The left surface of the reactor 100 is fixedly installed with a discharge pipe 101, and the discharge pipe 101 and The interior of the reaction kettle 100 is communicated, the upper surface of the reaction kettle 100 is fixedly installed with a feed pipe 102, and the feed pipe 102 is communicated with the interior of the reaction kettle 100, and the interior of the reaction kettle 100 is provided with a U-shaped groove 103, and the U-shaped groove Both ends of 103 are communicated with the interior of the reaction kettle 100, and the interior of the reaction kettle 100 is provided with a chute 104 at the corresponding position of the U-shaped groove 103, and the interior of the chute 104 and the U-shaped groove 103 are communicated, and the chute 104 The side wall of the reactor 100 is provided with a mounting groove 105, the insi...

Embodiment 2

[0038] combine figure 1 , figure 2 and image 3 As shown, based on the above-mentioned Embodiment 1, the stirring assembly 200 includes a motor 201, a rotating shaft 202, a mounting plate 203 and a stirring blade 204, the right side surface of the reaction kettle 100 is fixedly installed with the motor 201 through the fixing table, and the output shaft end of the motor 201 A rotating shaft 202 is fixedly installed on the outer surface of the rotating shaft 202, and the end of the rotating shaft 202 penetrates the right side wall of the reaction kettle 100, and the end of the rotating shaft 202 extends to the interior of the reaction kettle 100. The outer surface of the rotating shaft 202 is fixedly installed with two groups of Mounting plate 203, two sets of stirring blades 204 are symmetrically and fixedly connected between the two sets of mounting plates 203.

[0039] Based on the above structure, the motor 201 drives the rotating shaft 202 and the mounting plate 203 to r...

Embodiment 3

[0041] combine figure 2 , image 3 and Figure 4 As shown, based on the above-mentioned Embodiment 1 or 2, the linkage assembly 300 includes a rotating rod 301, a pulley A302, a pulley B303 and a transmission belt 304, the right side surface of the reaction kettle 100 is rotatably installed with the rotating rod 301, and the end of the rotating rod 301 Running through the right side surface of the reactor 100, and the end of the rotating rod 301 extends to the interior of the installation groove 105, the end of the rotating rod 301 located on the right side of the reactor 100 is fixedly installed with a pulley A302, and the outer surface of the rotating shaft 202 is connected to the pulley. A pulley B303 is sleeved at the position corresponding to A302. The outer surface of the pulley B303 and the transmission belt 304 is sleeved with a transmission belt 304. The end of the rotating rod 301 located inside the installation groove 105 is fixedly installed with a rotating disc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com