Infiltration method and device for large thin-wall part

A large-scale thin-walled parts, impregnation technology, applied in the field of impregnation, thin-walled parts production, can solve the waste of impregnating liquid, complex structure, time-consuming and other problems, to achieve short vacuuming time, small volume, low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Impregnation of large thin-walled parts

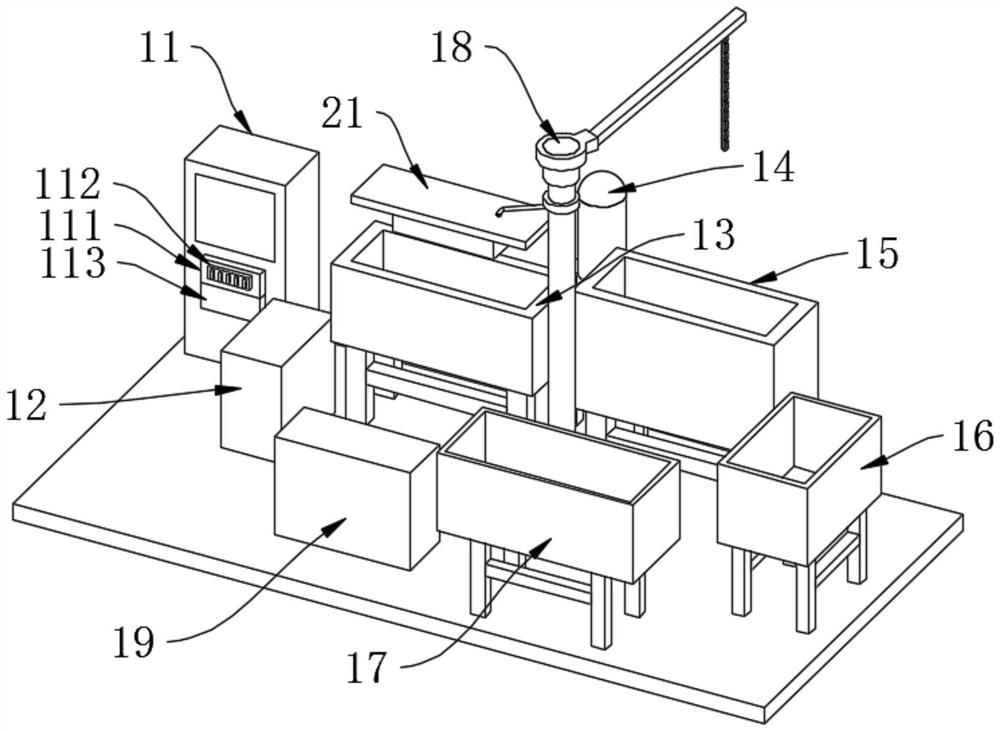

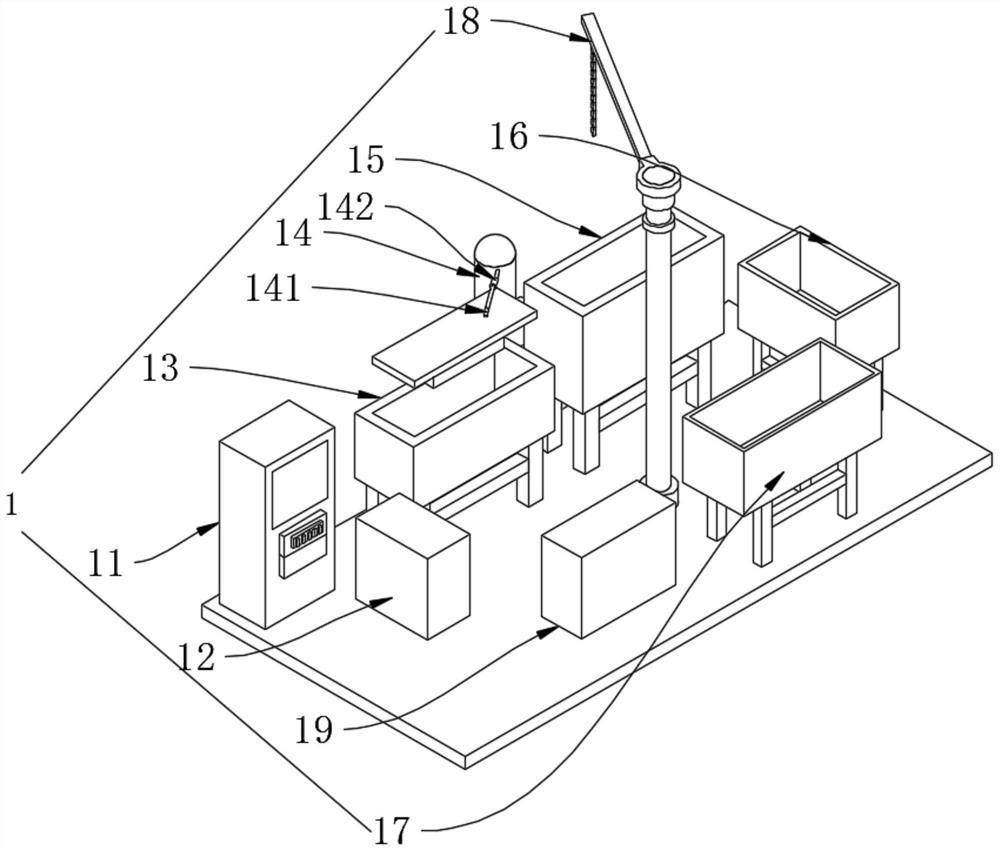

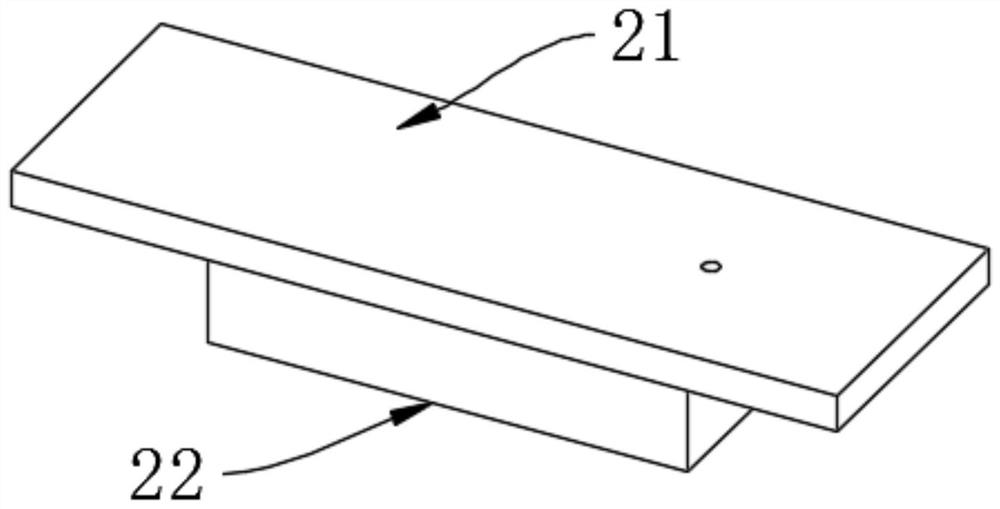

[0036]Including main assembly 1, main assembly 1 includes electric control cabinet 11, clamping table 12, vacuum sealing tooling assembly 2, impregnation tank 13, vacuum pump 14, air shower deliquoring tank 15, cleaning tank 16, hot water curing tank 17. Cantilever crane 18 and processing table 19, vacuum sealing tooling assembly 2 includes vacuum sealing plate 21 and adsorption seat 22, adsorption seat 22 is installed on the bottom of vacuum sealing plate 21 by bolts, electric control cabinet 11, clamping work The stage 12, the impregnation tank 13 and the air shower deliquoring tank 15 are arranged in sequence, the vacuum pump 14 is arranged on one side of the impregnation tank 13, the cleaning tank 16 is arranged on the side of the air shower deliquoring tank 15, and the hot water curing tank 17 is arranged on the cleaning tank. 16 side, the processing table 19 is set on the hot water curing pool 17 side, the canti...

Embodiment 2

[0044] Example 2: Casting Stability Monitoring

[0045] Including main assembly 1, main assembly 1 includes electric control cabinet 11, clamping table 12, vacuum sealing tooling assembly 2, impregnation tank 13, vacuum pump 14, air shower deliquoring tank 15, cleaning tank 16, hot water curing tank 17. Cantilever crane 18 and processing table 19, vacuum sealing tooling assembly 2 includes vacuum sealing plate 21 and adsorption seat 22, adsorption seat 22 is installed on the bottom of vacuum sealing plate 21 by bolts, electric control cabinet 11, clamping work The stage 12, the impregnation tank 13 and the air shower deliquoring tank 15 are arranged in sequence, the vacuum pump 14 is arranged on one side of the impregnation tank 13, the cleaning tank 16 is arranged on the side of the air shower deliquoring tank 15, and the hot water curing tank 17 is arranged on the cleaning tank. 16 side, the processing table 19 is set on the hot water curing pool 17 side, the cantilever cran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com