Preparation method of glutinous rice paper based on chitosan lipidosome

A chitosan and liposome technology, applied in the field of packaging materials, can solve the problems of reducing the efficacy of essential oils, low water solubility, etc., and achieve the effects of improving stability, strong hydrophobicity, and high antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

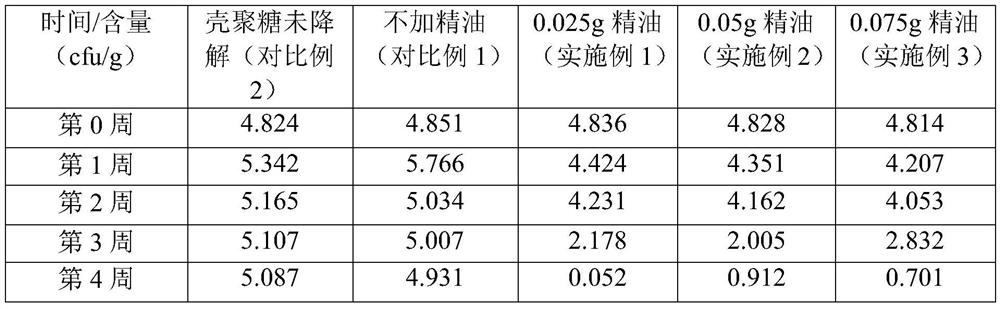

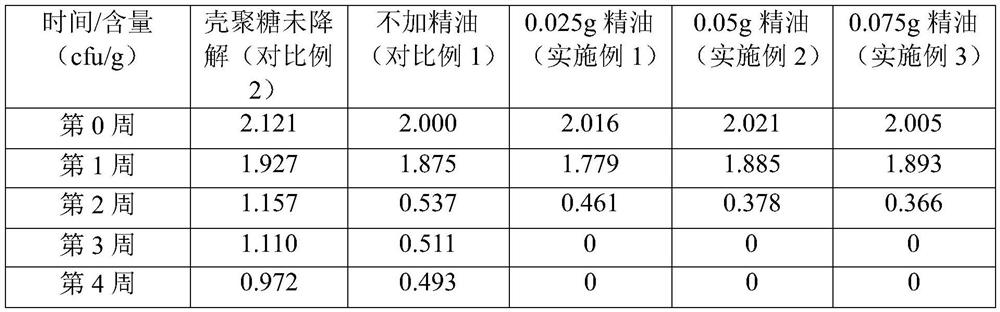

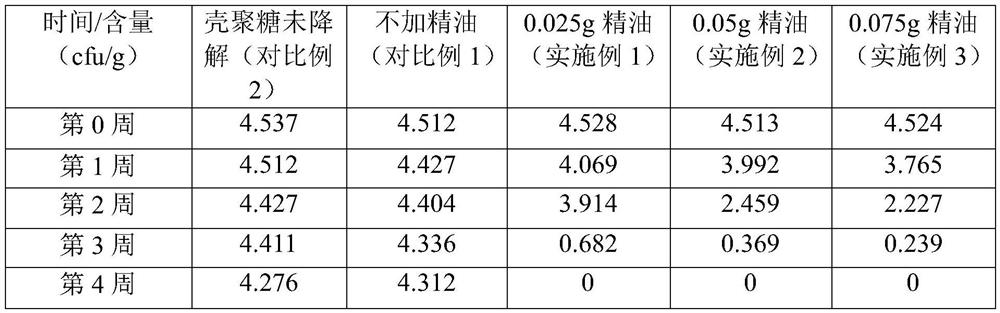

Examples

Embodiment 1

[0034] 1) Dissolving chitosan in a 2vol% hydrochloric acid solution to obtain a mixed solution;

[0035] 2) Add 0.2g NaNO to the mixed solution at room temperature in a mass ratio of 65:1 2 , react for 2h to obtain degraded chitosan, and store at 4°C for further use; 3) add 2g of lecithin to 50mL of chloroform solution dissolved with 0.025g of lemon essential oil, and stir at room temperature for 30min to dissolve;

[0036] 4) Add 50 mL of 3wt% degraded chitosan solution to the above mixture, and stir at 1500 rpm and 60° C. for 30 min to obtain a milky suspension;

[0037] 5) Concentrate the milky suspension obtained in step 4) under reduced pressure at 50° C. for 1 h until the solution is in the form of a paste;

[0038] 6) rehydrate the paste-like product obtained by concentrating in step 5) with distilled water, and adjust the solution volume to 60 mL;

[0039] 7) ultrasonically treating the emulsion after the volume adjustment in step 6) in an ultrasonic bath for 2 h, an...

Embodiment 2

[0043] A method for synthesizing waxy rice paper based on chitosan liposome, comprising the following steps:

[0044] 1) Dissolving chitosan in a 2vol% hydrochloric acid solution to obtain a mixed solution;

[0045] 2) Add 0.2g NaNO to the mixed solution at room temperature in a mass ratio of 65:1 2 , the degraded chitosan was obtained after the reaction for 2 h, and was stored at 4°C for further use;

[0046] 3) 2 g of lecithin was added to the 50 mL of chloroform solution in which 0.05 g of lemon essential oil was dissolved, and stirred at room temperature for 30 min to dissolve;

[0047] 4) Add 50 mL of 3wt% degraded chitosan solution to the above mixture, and stir at 1500 rpm and 60° C. for 30 min to obtain a milky suspension;

[0048] 5) Concentrate the milky suspension obtained in step 4) under reduced pressure at 50° C. for 1 h until the solution is in the form of a paste;

[0049] 6) rehydrate the paste-like product obtained by concentrating in step 5) with distille...

Embodiment 3

[0054] A method for synthesizing waxy rice paper based on chitosan liposome, comprising the following steps:

[0055] 1) Dissolving chitosan in a 2vol% hydrochloric acid solution to obtain a mixed solution;

[0056] 2) Add 0.2g NaNO to the mixed solution at room temperature in a mass ratio of 65:1 2 , the degraded chitosan was obtained after the reaction for 2 h, and was stored at 4°C for further use;

[0057] 3) 2 g of lecithin was added to the 50 mL of chloroform solution in which 0.075 g of lemon essential oil was dissolved, and stirred at room temperature for 30 min to dissolve;

[0058] 4) Add 50 mL of 3wt% degraded chitosan solution to the above mixture, and stir at 1500 rpm and 60° C. for 30 min to obtain a milky suspension;

[0059] 5) Concentrate the milky suspension obtained in step 4) under reduced pressure at 50° C. for 1 h until the solution is in the form of a paste;

[0060] 6) rehydrate the paste-like product obtained by concentrating in step 5) with distill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com