Device for refining high-purity hypereutectic niobium-chromium-containing 8 cast iron and application thereof

A hypereutectic and pure technology, which is applied in the direction of casting equipment, casting molten material container, process efficiency improvement, etc., can solve the problems of inability to detect the degree of inert gas flushing, high cost, and failure to avoid furnace accidents. Achieve the effects of avoiding furnace break-through accidents, saving costs, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

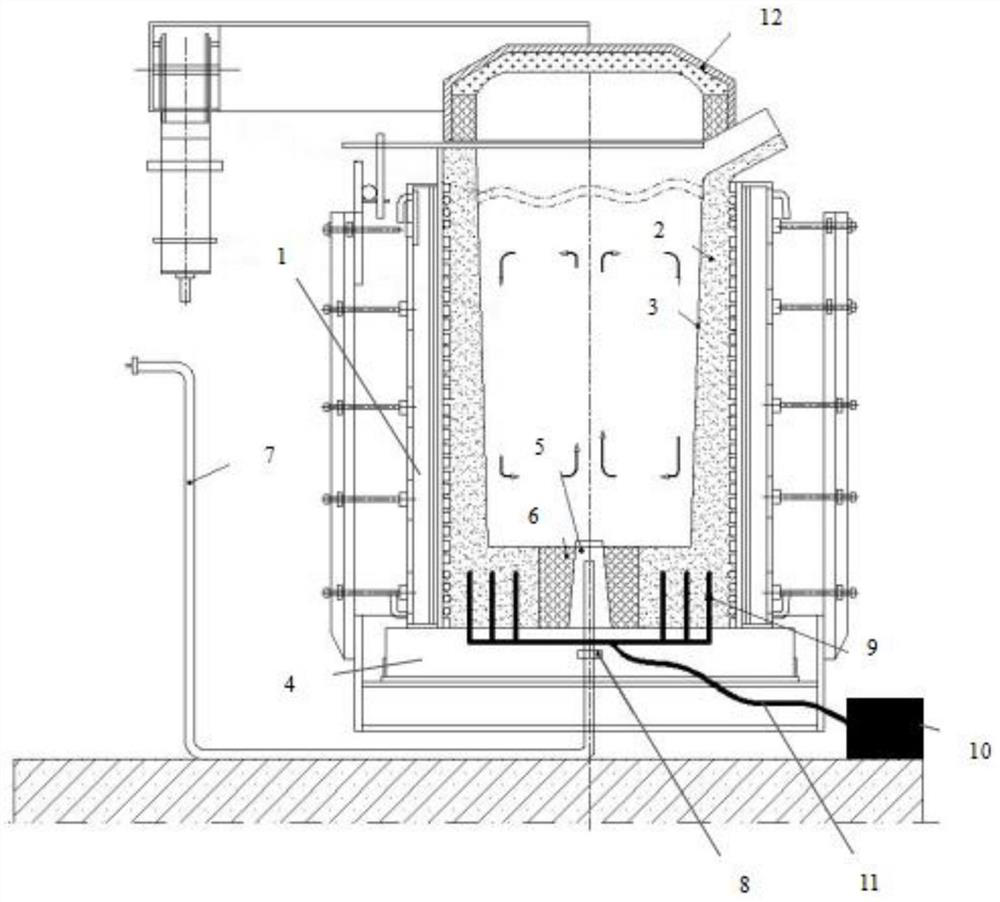

[0033] like figure 1 As shown in the figure, a device for refining high-purity hypereutectic niobium-chromium-8 cast iron, comprising: a casing 1, a refractory lining 2, a wall layer 3, a base 4, a gas diffuser 5, a ventilation block 6, an air inlet pipe 7, and a union 8 , bottom protection contact 9, contact protector 10, wire 11, cover 12, the casing 1 is wrapped with a refractory lining 2, the outer surface of the refractory lining 2 is provided with a wall layer 3, and the bottom of the casing 1 is provided with There is a base 4, a gas diffuser 5 and a breathable block 6 are arranged above the base 4, the breathable block 6 wraps the gas diffuser 5, the air inlet pipe 7 is connected with the gas diffuser 5, and the live joint 8 is connected to the gas diffuser 5. The air intake pipe 7 is connected and fixed on the base 4, the bottom protection contact 9, the contact protector 10, and the wire 11 constitute a refractory lining protection device, and the bottom protection c...

Embodiment 2

[0042] like figure 1 As shown in the figure, a device for refining high-purity hypereutectic niobium-chromium-8 cast iron, comprising: a casing 1, a refractory lining 2, a wall layer 3, a base 4, a gas diffuser 5, a ventilation block 6, an air inlet pipe 7, and a union 8 , bottom protection contact 9, contact protector 10, wire 11, cover 12, the casing 1 is wrapped with a refractory lining 2, the outer surface of the refractory lining 2 is provided with a wall layer 3, and the bottom of the casing 1 is provided with There is a base 4, a gas diffuser 5 and a breathable block 6 are arranged above the base 4, the breathable block 6 wraps the gas diffuser 5, the air inlet pipe 7 is connected with the gas diffuser 5, and the live joint 8 is connected to the gas diffuser 5. The air intake pipe 7 is connected and fixed on the base 4, the bottom protection contact 9, the contact protector 10, and the wire 11 constitute a refractory lining protection device, and the bottom protection c...

Embodiment 3

[0051] like figure 1As shown in the figure, a device for refining high-purity hypereutectic niobium-chromium-8 cast iron, comprising: a casing 1, a refractory lining 2, a wall layer 3, a base 4, a gas diffuser 5, a ventilation block 6, an air inlet pipe 7, and a union 8 , bottom protection contact 9, contact protector 10, wire 11, cover 12, the casing 1 is wrapped with a refractory lining 2, the outer surface of the refractory lining 2 is provided with a wall layer 3, and the bottom of the casing 1 is provided with There is a base 4, a gas diffuser 5 and a breathable block 6 are arranged above the base 4, the breathable block 6 wraps the gas diffuser 5, the air inlet pipe 7 is connected with the gas diffuser 5, and the live joint 8 is connected to the gas diffuser 5. The air intake pipe 7 is connected and fixed on the base 4, the bottom protection contact 9, the contact protector 10, and the wire 11 constitute a refractory lining protection device, and the bottom protection co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com