Composite dry vacuum pump with Roots rotors and screw rotors connected in series and use method of composite dry vacuum pump

A technology of dry vacuum pump and screw pump, applied to rotary piston/oscillating piston pump components, rotary piston/oscillating piston pump combinations for elastic fluids, components of pumping devices for elastic fluids, etc. Direction, it can solve the problems that cannot be actually produced and used, the pumping speed ratio cannot be too large, and the pumping efficiency is reduced, so as to achieve obvious energy-saving effect, enhanced safety, and avoid over-compression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

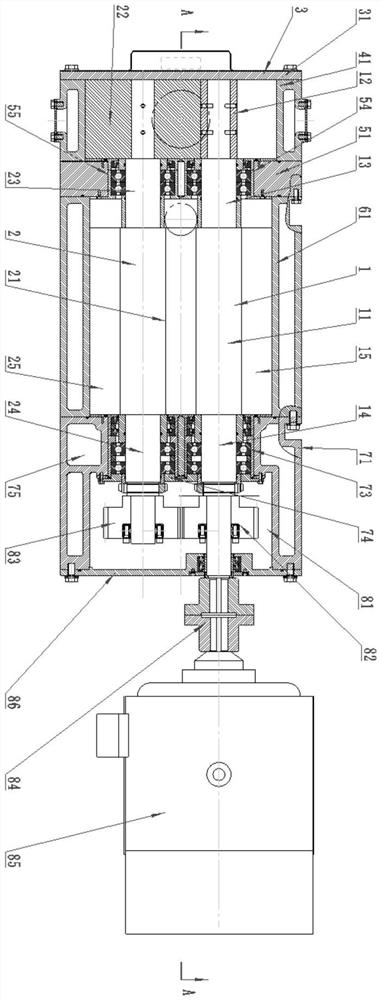

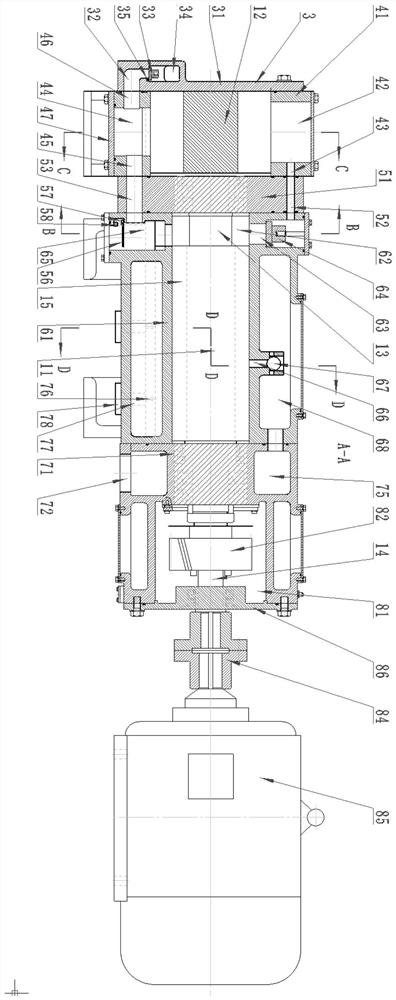

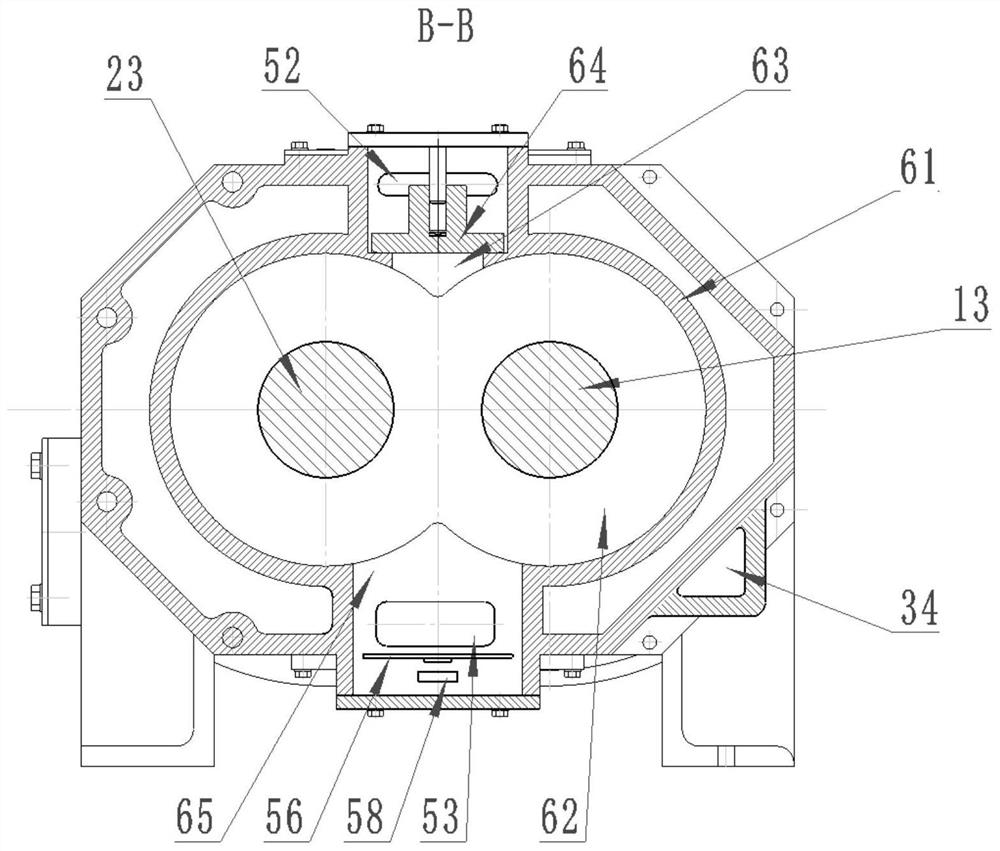

[0040] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below through specific implementation manners in conjunction with the accompanying drawings.

[0041] like Figure 1-5 As shown, a compound dry vacuum pump with a Roots rotor and a screw rotor connected in series, including a driving rotor combination 1, a driven rotor combination 2 and a pump body combination 3, the driving rotor combination 1 includes a driving screw rotor body 15 processed in the middle The active rotor shaft 11 and the active Roots rotor body 12 set on the active front end shaft 13, the active front end shaft 13 is coaxially connected to the front end of the active rotor shaft 11; the driven rotor combination 2 includes a driven screw rotor body 25 processed in the middle The driven rotor shaft 21 and the driven Roots rotor body 22 sleeved on the driven front shaft 23, the driven fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com