Construction waste conversion matrix for sedum lineare roof greening and application thereof

A construction waste and roof greening technology, which is applied in the field of construction waste conversion matrix, can solve the problems of poor ventilation and storage capacity, unstable structure, complicated preparation process, etc., and achieve reduced roof load, strong air permeability, and plant growth promotion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this example, the proposed planting 50m 2For the roof of sedum plants, after completing the construction of roof waterproofing and root layer, and before preparing the substrate layer for construction, transport the materials to the roof greening site. The preparation of a roof greening construction waste conversion matrix includes materials: fine peat soil, two kinds of red brick particles with different particle size ranges, concrete particles, and environment-friendly pumice particles. The preparation method of the substrate is as follows: according to the plant species, the particle size of the peat soil is selected. The test plant is Sedum sedum. Due to the extrusion and compaction of the peat soil during transportation, the fine peat soil is passed through a 10mm mesh screen, and the The fine peat soil that passes through the sieve is not used, and passes through the 10mm sieve for use; the recycled construction waste red bricks are mechanically pulverized, pas...

Embodiment 2

[0037] Experiment on the effect of cultivation on the substrate of foetida

[0038] 1.1 Materials to be tested

[0039] The test plant is Sedum sedum, which has growth characteristics such as drought tolerance and nutrient-poor resistance, and is a good light roof greening plant.

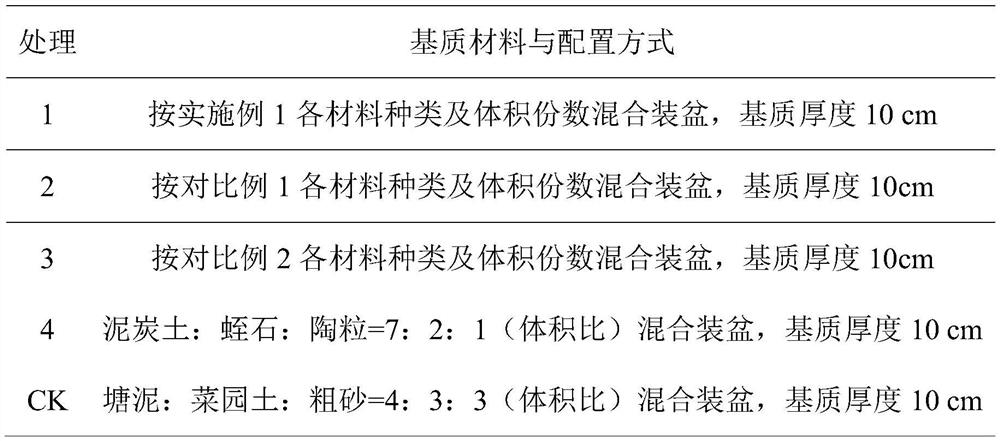

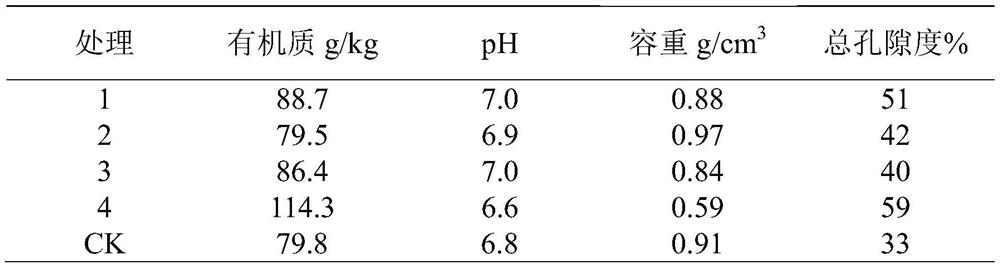

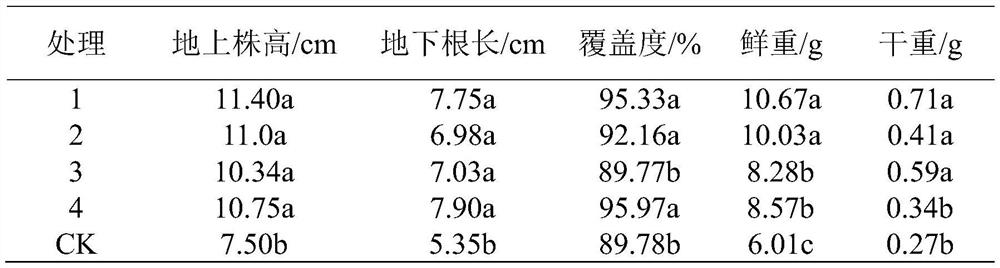

[0040] 1.2 Test treatment

[0041] In this study, 5 matrix treatments were set up according to different matrix components and different preparation methods (as shown in Table 1). The tested plants were all used in lightweight boxes, the practical length of the lightweight box was 38cm, the width was 29cm, and the height was 13cm, and were planted by cuttings. Before planting, the substrates with different treatments were placed in pots according to Table 1, and then the prepared sedum plants were evenly inserted into the pots. The cultivation density is 6 plants / pot. The thickness of the planting layer was 10 cm, and each treatment was repeated 3 times. The cultivation and growth period was ni...

Embodiment 3

[0059] Compared with Example 1, most of them are the same, except in this example, the volume fractions of peat soil, red brick particles, concrete particles and environmental pumice particles are adjusted to 15 parts, 10 parts, 3 parts, 3 copies.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com