Hydrogel patch comprising syneresis mode adjusting filling liquid and preparation method thereof

A hydrogel patch and syneresis technology, applied in skin care preparations, medical preparations containing active ingredients, pharmaceutical formulations, etc., can solve problems not specifically raised, achieve good physical properties, and improve transdermal delivery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

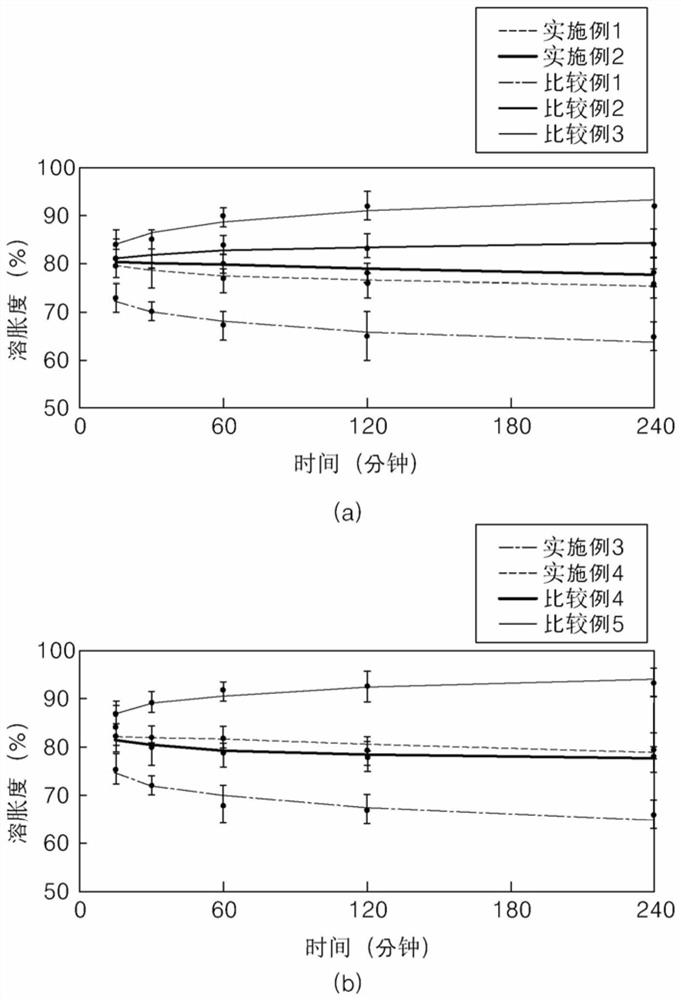

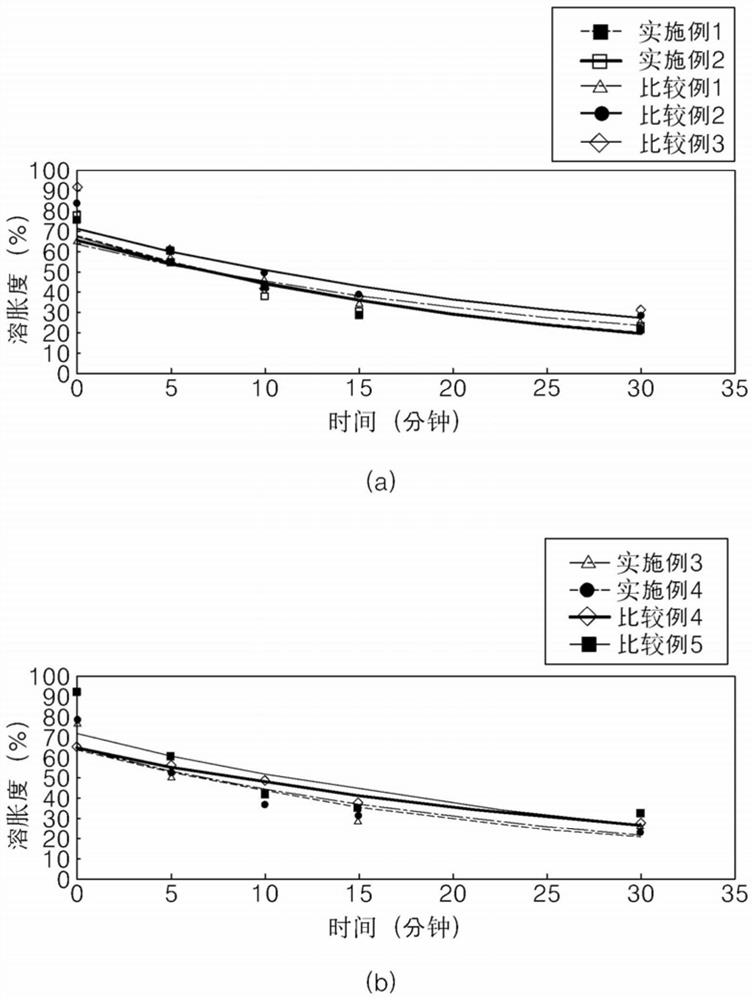

Examples

preparation example Construction

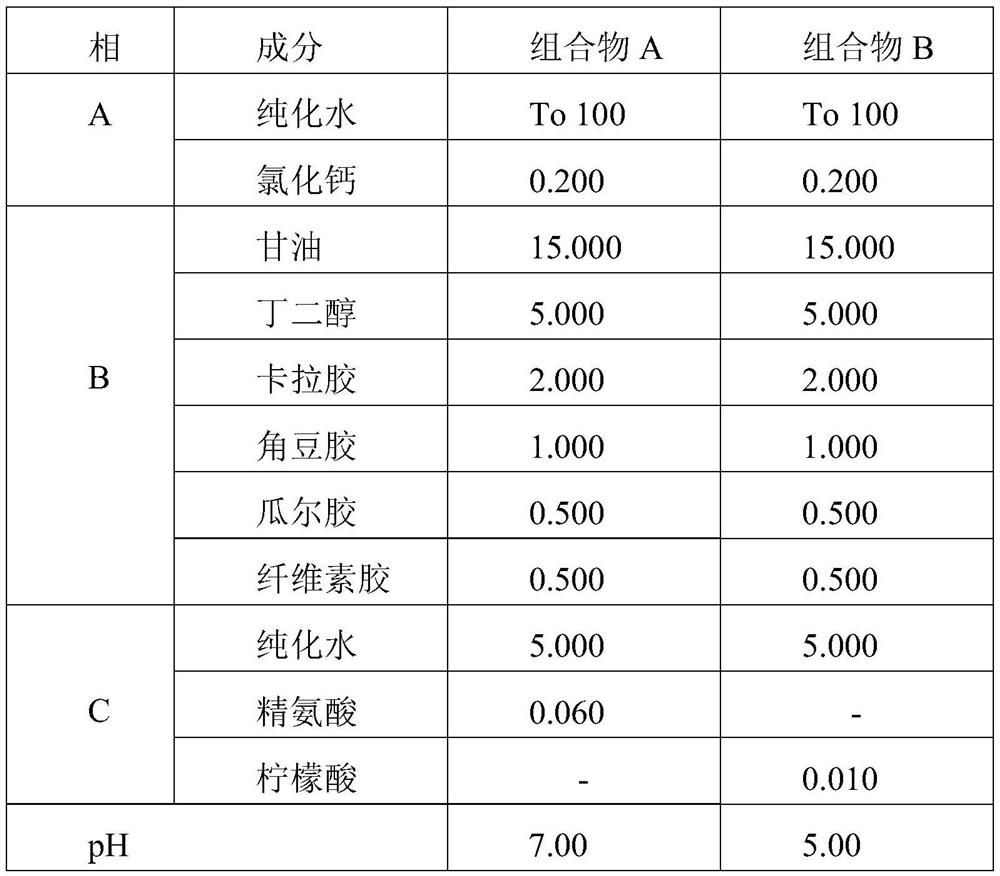

[0041] The preparation method of the hydrogel is performed by dividing the raw materials into the A phase, the B phase and the C phase, and then adding the B and C phases to the A phase after stirring, respectively. Stir at 800 rpm for 5 minutes at 85°C in phase A, at 800 rpm at room temperature for 5 minutes in phase B, and at 800 rpm at room temperature for 5 minutes in phase C. Then, after adding phase B to the said A phase, it stirred at 1000-3000 rpm for about 5 minutes at 70-95 degreeC, and after injecting into C phase, it stirred at 1000-3000 rpm at 70-95 degreeC for about 5 minutes. After applying a high-temperature hydrosol with a roll of 0.1 to 5 mm together with the plastic film paper, it is cooled at 1° C. to normal temperature until the hydrogel reaches normal temperature to complete the hydrogel sheet. In order to measure the pH of the completed hydrogel sheet, 4 g of the hydrogel and 60 g of purified water were put into it, fully swollen on a heating stirrer wit...

Embodiment 1

[0059] Hydrogel Preparation Composition A of Example 1. According to the stirring conditions of the separated phases, phase A was stirred at 85°C at 800 rpm for 5 minutes, phase B was stirred at 800 rpm at room temperature for 5 minutes, and phase C was stirred at 800 rpm at room temperature for 5 minutes. , and stirred at 2000 rpm for 5 minutes at 85°C, and after adding phase C, the mixture was stirred at 85°C at 2000 rpm for 5 minutes. After that, it was coated with a thickness of 2.0 mm, cooled at room temperature, and then molded into a circle having a diameter of 75 mm. The fill liquid of Example 1 prepared Composition C. The stirring conditions of the separated phases were as follows: Phase D was stirred at 800 rpm for 5 minutes at 80°C, Phase E was stirred at 800 rpm for 5 minutes at room temperature, and Phase F was stirred at 800 rpm for 5 minutes at room temperature. , and stirred at 500 rpm for 5 minutes at 80°C, and after adding the F phase, the mixture was stirr...

Embodiment 2

[0061] The same procedure as in Example 1 was carried out, except that a 78 mm circular container was filled so that the hydrogel of the composition A was 80 g and the filling liquid of the composition C was 20 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com