Coal mill primary air control logic optimization method

A technology of control logic and optimization method, applied in the direction of comprehensive factory control, grain processing, etc., to achieve the effect of increased reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

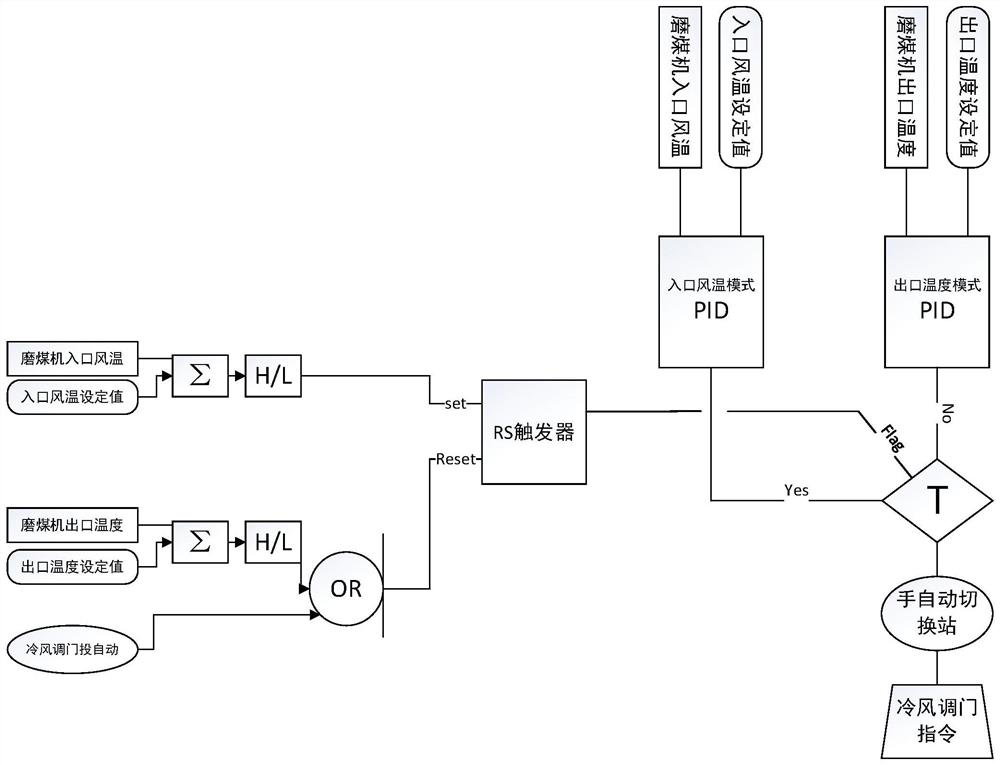

[0026] refer to figure 1 , which is the first embodiment of the present invention, which provides a method for optimizing primary air control logic of a coal mill, including:

[0027] S1: Sum the actual value of the inlet temperature of the coal mill and the set value of the inlet temperature of the coal mill, and input the operation result to the signal judgment module, and the output of the signal judgment module is input to the RS trigger through the Set terminal.

[0028] like figure 1 As shown in the figure, the actual value of the inlet temperature of the coal mill and the set value of the inlet temperature of the coal mill are summed, and the calculation result is input to the signal judgment module (H / L).

[0029] S2: When the actual value of the inlet temperature of the coal mill is greater than the set value of the inlet temperature of the coal mill, the RS trigger sends the first signal to the switching module, and the entire cold air regulating door command is swi...

Embodiment 2

[0044] In order to verify and illustrate the technical effect adopted in this method, this embodiment selects the traditional technical solution and adopts this method to carry out comparative test, and compares the test results by means of scientific demonstration to verify the real effect of this method.

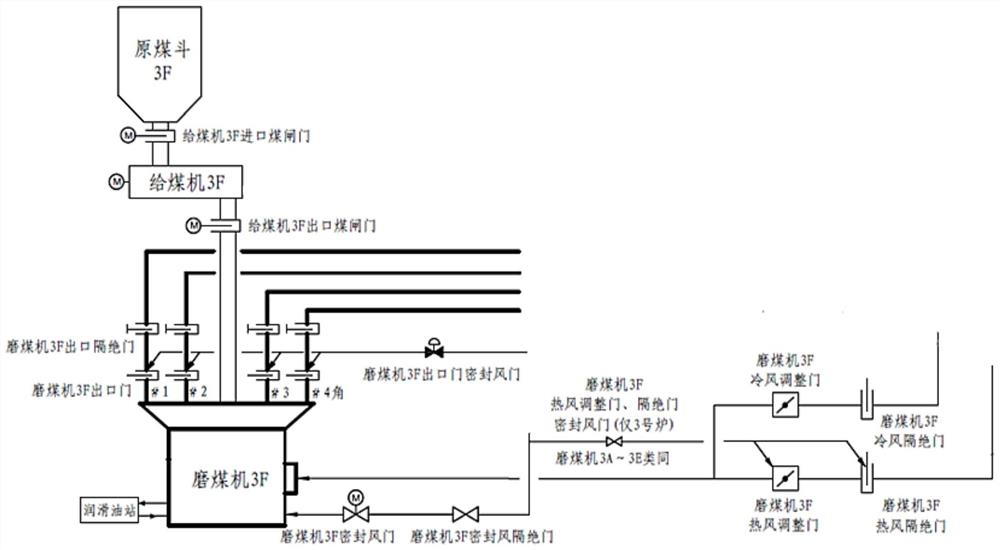

[0045] like figure 2 As shown, each coal mill is equipped with a pneumatic isolation door for cold air, an electric adjustment door for cold air, a pneumatic isolation door for hot air and an electric adjustment door for hot air.

[0046] This embodiment adopts the traditional technical solution and this method respectively to figure 2 The coal mill shown was controlled to compare the performance of the traditional technical solution and this method, and the results are shown in the following table.

[0047] Table 1: Control performance comparison.

[0048] traditional technical solutions this method Outlet air temperature mode can be switched ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com